|

|||

|

|

|||

|

Page Title:

Table 4-1. Preventive-Maintenance Checks and Services |

|

||

| ||||||||||

|

|

TM 3-1040-214-12

4-19. Servicing After Use

After disperser has been used by the operator, perform

(1) Disassemble the M9 gun (para 4-14).

the following operations:

(2) Inspect rubber tube for holes, cracks, and

deterioration.

Check especially the area that is

a. Check to see that the operator performed

squeezed by the trigger.

cleaning operations (para 2-10).

(3) Inspect rubber tube sleeve and connector

b. Decontaminate the disperser if agent has been

for damage.

used (para 4-12 through 4-15). If T1 (talc) has been

used, clean the tank group with air pressure

(4) Inspect barrel section for cracks, dents,

and defective threads.

Inspect locknut threads for

damage. Inspect collar and setscrews for damage.

1-5) including

(5) Inspect valve section parts for damage,

attaching parts for damaged and missing parts.

dents, and defective threads. Check cover plate for

damage and missing screws Operate and check trigger

parts for damage.

and trigger safety for proper operation.

Open end

(6) Stow the rubber tube in the packing chest

should be free of foreign material.

as a separate item.

(7) Stow the disassembled gun in the packing

chest.

and cotton cord for damage, mildew, rot, and wear.

Check all attaching buckles, hardware, and carrier frame

4-20. Preventive-Maintenance Checks and Services

for damage and missing parts.

a. Purpose. The preventive-maintenance checks

and services (table 4-1) provide organizational

and deterioration.

maintenance personnel with a list of maintenance

services which must be performed at the intervals

WARNING

prescribed. Use the list to make sure that all required

Unserviceable hose assemblies must

maintenance is accomplished. If corrective action is not

be replaced. No repair is authorized.

authorized at organizational level, report equipment

defects to direct support maintenance personnel.

b. Explanation of Columns. A number under the

h. Inspect quick-disconnect coupling half for

sequence number column indicates that the service

damage. Check inner balls and ball depressing ring for

opposite the number must be performed monthly in

ease of operation.

Check inner rubber gasket for

numerical sequence.

damage and deterioration.

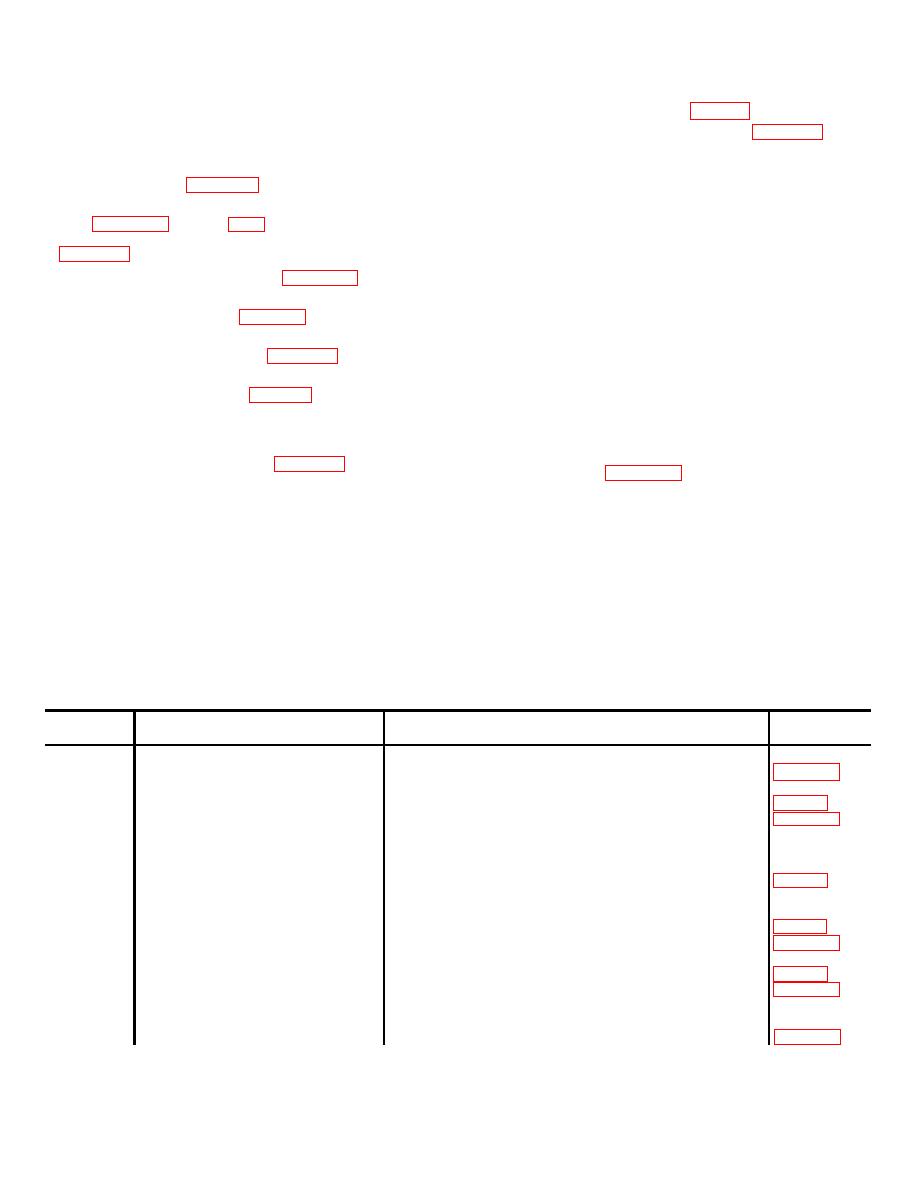

Table 4-1. Preventive-Maintenance Checks and Services

Organizational Maintenance Category

Monthly Schedule

Sequence

Paragraph

No

Item to be inspected

Procedure

reference

GUN GROUP

1

M9 gun -----------------------------------------

Inspect M9 gun for damage -------------------------------------------

2

Rubber tube, collar connector, and

Inspect rubber tube for holes, cracks, and deterioration.

sleeve.

Check especially the area that is collapsed by the

operation of the trigger. Inspect sleeve and connector

for damage. Replace parts as authorized.

3

Valve section ---------------------------------

a. Inspect the valve section for damage. Inspect threads

for damage.

b. Check cover plate for damage and missing screws --------

c. Operate the trigger and trigger safety catch for

proper operation. Check for missing or damaged

parts. Replace parts as authorized.

d. Adjust trigger if required --------------------------------------------

4-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |