|

|||

|

|

|||

|

Page Title:

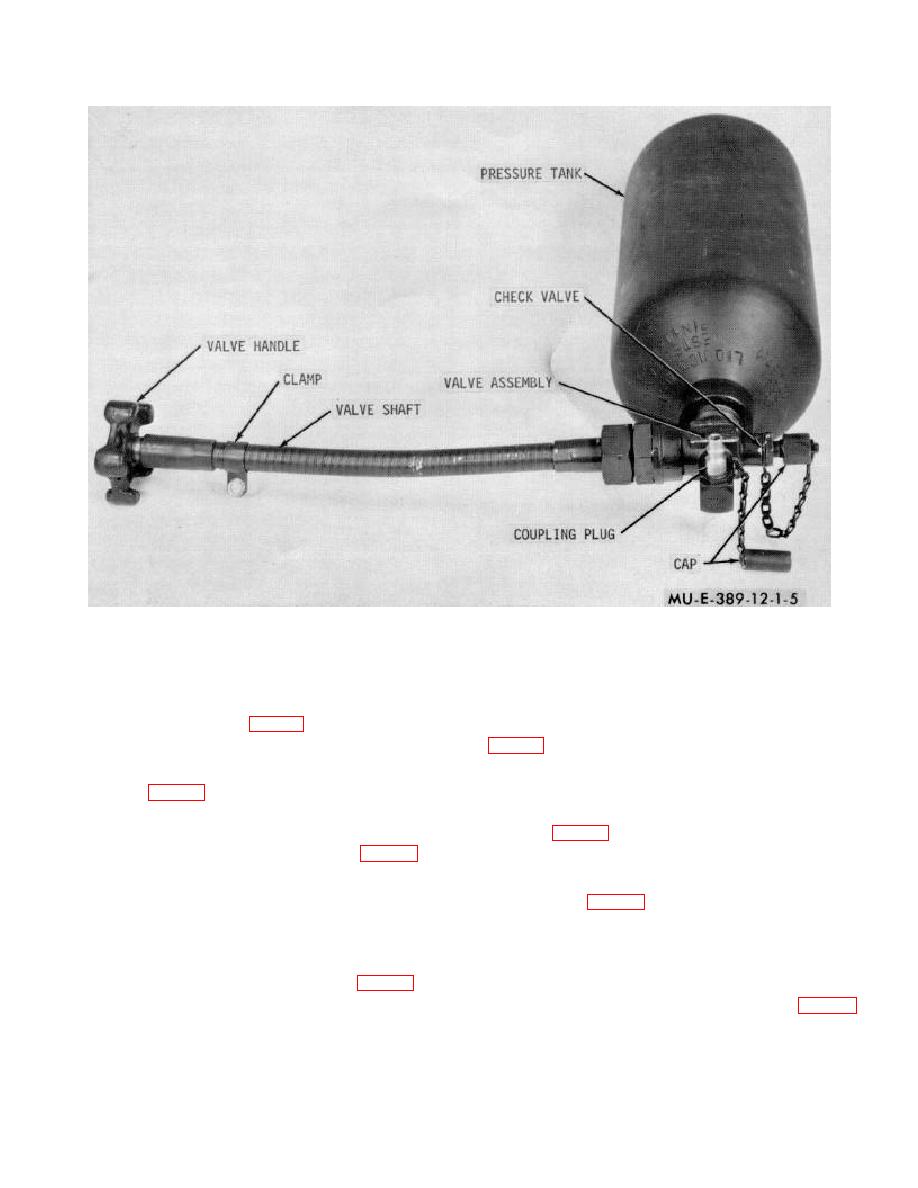

Figure 1-5. Pressure tank and valve assembly. |

|

||

| ||||||||||

|

|

TM 3-1040-214-12

Figure 1-5. Pressure tank and valve assembly.

clamp and wingnut.

For maximum efficiency, air

safety valve contains a replaceable safety head

pressure is between 1,700 psi and 2,100 psi.

containing a disk that will rupture when air pressure

exceeds 150 psi 25 psi.

(2) Pressure regulator and tube assembly.

One end of a tube assembly (fig. 1-6) is connected to the

(5) Shutoff valve and handle. A shutoff valve

inlet side of the pressure regulator. The other end of the

tube assembly contains a quick-disconnect coupling half.

and the diffusion pipe assembly. A shutoff valve handle,

This coupling is the connection for the pressure tank

turned counterclockwise, opens the shutoff valve and

coupling plug (fig. 1-5). The pressure regulator reduces

permits pressurized air in the agent tanks and the

the air pressure coming from the pressure tank.

diffusion pipe assembly to escape through the vent tube

assembly (fig. 1-7) and into the atmosphere.

(3) Safety

valve

adapter

and

hose

b. Agent Section.

connected to the safety valve adapter.

The quick

(1) Pipe and cap assembly. The pipe and

disconnect coupling half on the other end of each hose

cap assembly (fig. 1-6) is screwed into the top of each

assembly is connected to the pipe and cap assembly.

agent tank. A hose assembly is connected to each of

Pressurized air from the pressure regulator passes

the pipe and cap assemblies. Pressurized air passes

through the safety valve adapter, hose assemblies, and

through the hose assemblies, pipe and cap assemblies,

into each agent tank.

and into each agent tank. The safety valve adapter also

(4) Safety valve. The safety valve (fig. 1-7) is

contains a second air route to relieve air pressure from

connected between the outlet side of the pressure

the agent tanks through the diffusion pipes (fig. 1-7),

regulator and safety valve adapter. The bottom of the

shut-off

1-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |