|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

general check to indicate the equipment which probably

14. Connections

has been shipped.

d. Check the overall equipment for any loss or

Determine the voltage, type of current available, and

damage that might have occurred during shipment. If

the type of enlarger to be used (par. 4). Check to see

the equipment has been damaged or is incomplete, refer

that all switches are in the OFF position. See that the

to paragraph 2.

corrective voltage lamps (110-volt or 6-volt) are in the

e. If the equipment has been used or

safelight and in the enlarger body. If the lamp must be

reconditioned, check to see whether it has been changed

changed, refer to paragraph 36a.

by a modification work order (MWO). If modified, the

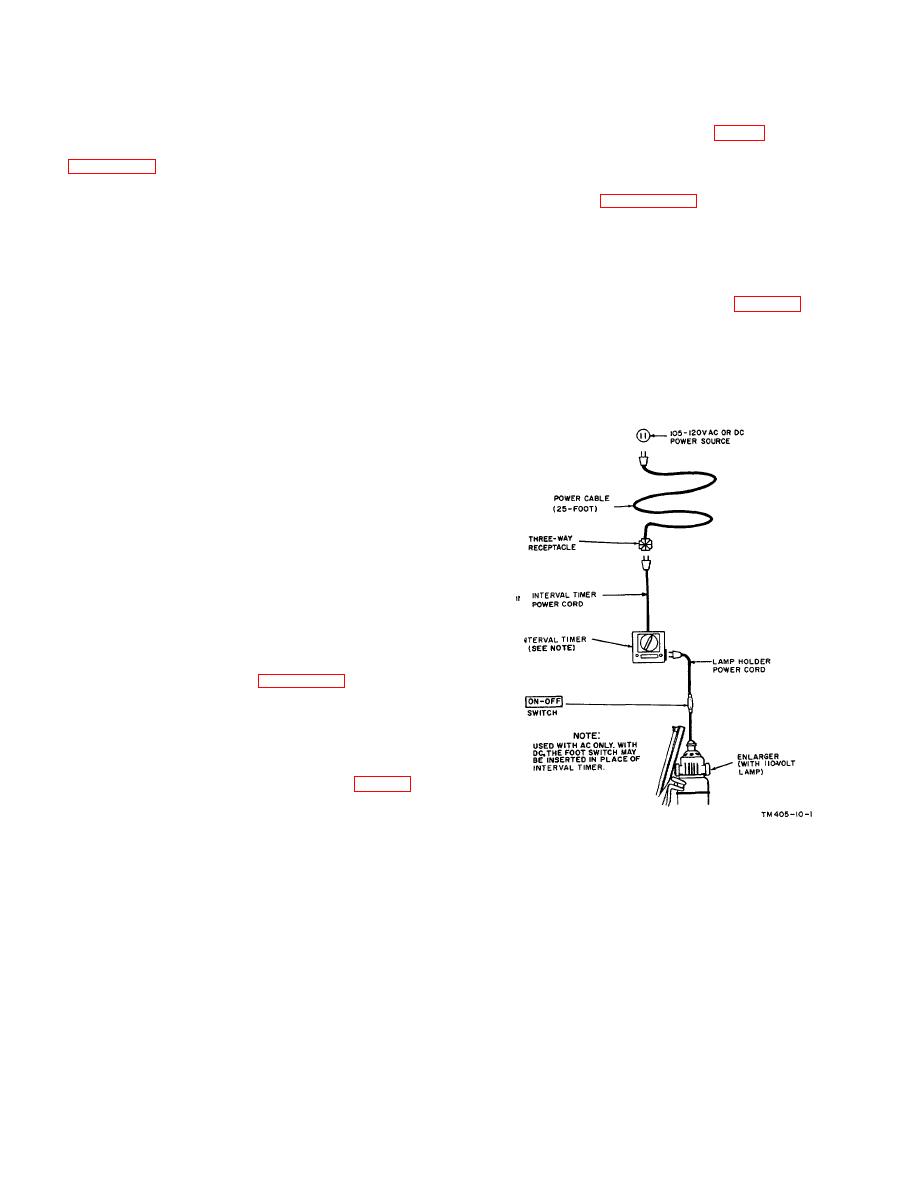

a. PH-129, PH-129-B, or EN-16 (1). Connect the

MWO number will be marked on the front of the enlarger

power cable (25-foot) to a 105- to 120-volt ac or dc

body.

power source. Connect the remainder of the equipment

12. Siting

as follows:

(1) If the power source is ac, connect the

equipment as shown in figure 11.

a. Exterior Requirements. The site where the

(2) If the power source is dc, replace the

processing set will be located is governed by the tactical

interval timer with a foot switch.

situation and by the type of housing facilities available

b. PH-129-A or PH-639(*)/TF. The procedure for

(tents, buildings, etc.). If possible, choose a location

connecting the PH-129-A or the PH639(*)/TF to an ac

where a fiat area is available for setting up the

power source is covered in (1) below. The procedure for

equipment.

Be sure that drainage facilities are

connecting to a dc power source is covered in (2) below.

adequate.

(1) General. After locating the shelter in

which the processing set is to be placed,

make the necessary arrangements for

darkroom operation. Equip all windows

with material to prevent the passage of

light. Shelters should be light tight.

Note.

Refer to TM 11-401 for details of shelter

(darkroom)

requirements.

(2) Space

Requirements.

Operating

personnel must have sufficient space and

table area to allow the work of developing

and printing.

The minimum space

required is 8 by 8 by 8 feet.

(3) Electrical requirements. For the power

requirements of the enlarger and the

safelight refer to paragraph 4.

(4) Water requirements. Large quantities of

fresh water (running water for 8 to 12

changes) are needed for washing prints

and negatives.

13. Assembly and Installation The processing set

must be assembled and installed on the site (par. 12) at

which it is to be operated. At this time arrangements

should be made to secure the services of organizational

maintenance personnel for assembly and installation of

the equipment.

TM405-10-1

Figure 11. Connection diagram for 105- to 120-volt ac or

dc of PH-129, PH-1 29-B, or EN-16(1).

AGO 5894A

17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |