|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 3-1040-214-12

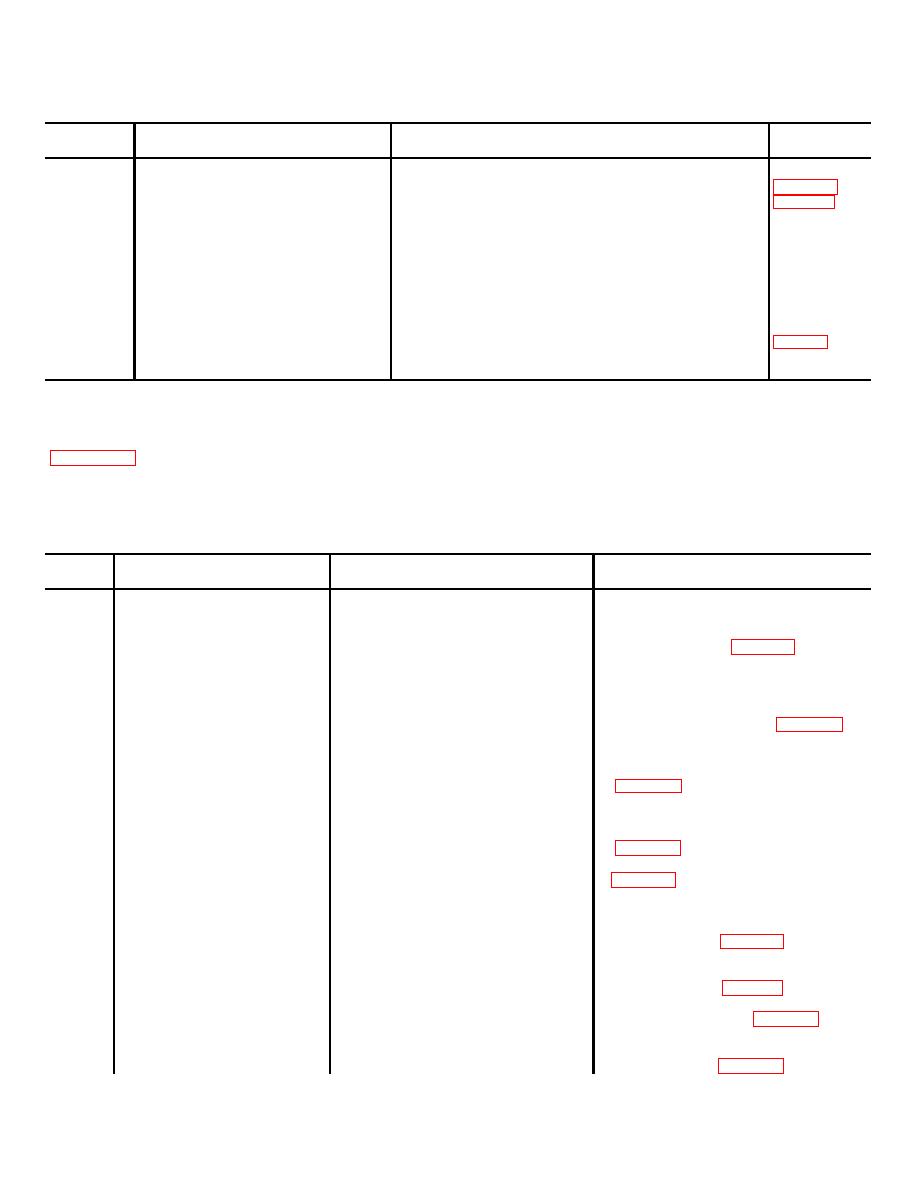

Table 4-1. Preventive-Maintenance Checks and Services-Continued

Organizational Maintenance Category

Monthly Schedule

Sequence

Paragraph

No

Item to be inspected

Procedure

reference

GENERAL

20

Exposed-metal painted surfaces on dis-

Inspect painted surfaces for corrosion, rust, and chipped

perser.

paint. Clean and repaint surfaces as required.

ACCESSORY GROUP

21

Publications -----------------------------------

See that a copy of TM 3-1040-214-12 is packed with

the equipment.

22

Gloves ------------------------------------------

Inspect gloves for tears and deterioration. Replace

gloves as required.

REPAIR PARTS

23

Connector, safety heads, check valves

Inspect for damage and deterioration. Replace parts as

preformed packing, washers, and

authorized.

rubber tube.

Section VI. TROUBLESHOOTING

4-21. General

4-22. Troubleshooting

for

Report all malfunction beyond

the scope of

organizational maintenance personnel.

organizational

maintenance

to

direct

support

maintenance personnel.

Table 4-2. Troubleshooting

Item

No.

Malfunction

Probable cause

Corrective action

1

Agent leaks at connection be-

Loose connection between gun and

Tighten connection.

tween gun and hose cou-

hose.

pling.

2

Agent leaks at trigger or

Rubber tube defective -------------------------

Replace rubber tube (para 4-24).

locknut.

3

Agent leaks at agent delivery

a. Quick-disconnect coupling half not

Disconnect quick-disconnect coupling

pipe coupling and quick-

installed properly on delivery

half and connect correctly.

disconnect coupling half on

pipe coupling.

hose assembly.

b . Preformed packing in quick-discon-

Replace preformed packing (para 4-27b).

nect coupling half missing or

damaged.

c. Defective quick-disconnect coupling

Replace quick-disconnect coupling half

half.

4

Agent leaks between pipe and

a. Tank cap loose------------------------------

Handtighten tank cap.

cap assembly and agent

b . Tank cap threads dirty---------------------

Clean threads.

tank.

c. Preformed packing rings missing

Replace preformed packing rings

or damaged.

d. Damaged pipe and cap assembly------

Replace pipe and cap assembly

5

Agent leaks between pipe

a. Quick-disconnect coupling half not

Disconnect quick-disconnect coupling

and cap assembly and hose

installed properly on pipe and

half and connect correctly.

assembly quick-disconnect

cap connector.

half.

b . Pipe and cap connector defective ------

Replace connector (para 4-28).

6

No discharge of agent when

a. Pressure tank valve closed --------------

Fully open pressure tank valve (turn

trigger is pressed.

handle counterclockwise).

b . Agent tank empty---------------------------

Fill tanks with agent (para 4-8).

c. Insufficient pressure in pressure

Replace pressure tank with a fully

tank.

charged pressure tank (para 4-10).

7

Trigger or trigger safety in-

a. Dirt accumulated under trigger

Clean.

operative.

safety.

b . Safety catch improperly adjusted ------

Adjust safety catch (para 4-25).

4-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |