|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 11-6665-232-40

be overlooked. If present, this type of trouble

ate (center) position. The pointer of the meter

often may be made to appear by tapping or jar-

should return to 0.

ring the equipment. Check the wiring (fig. 3-5

and 3-6) and connections within the radiacme-

mined that the radiacmeter is operating nor-

ter.

mally (b above), install the radiacmeter in the

(6) Calibration check. A calibration check

AN/USM-2 and perform the calibration check

procedure as instructed in TM 11-6665-227-12.

obtained from the radiacmeter are accurate.

The radiacmeter is exposed to known dose rates

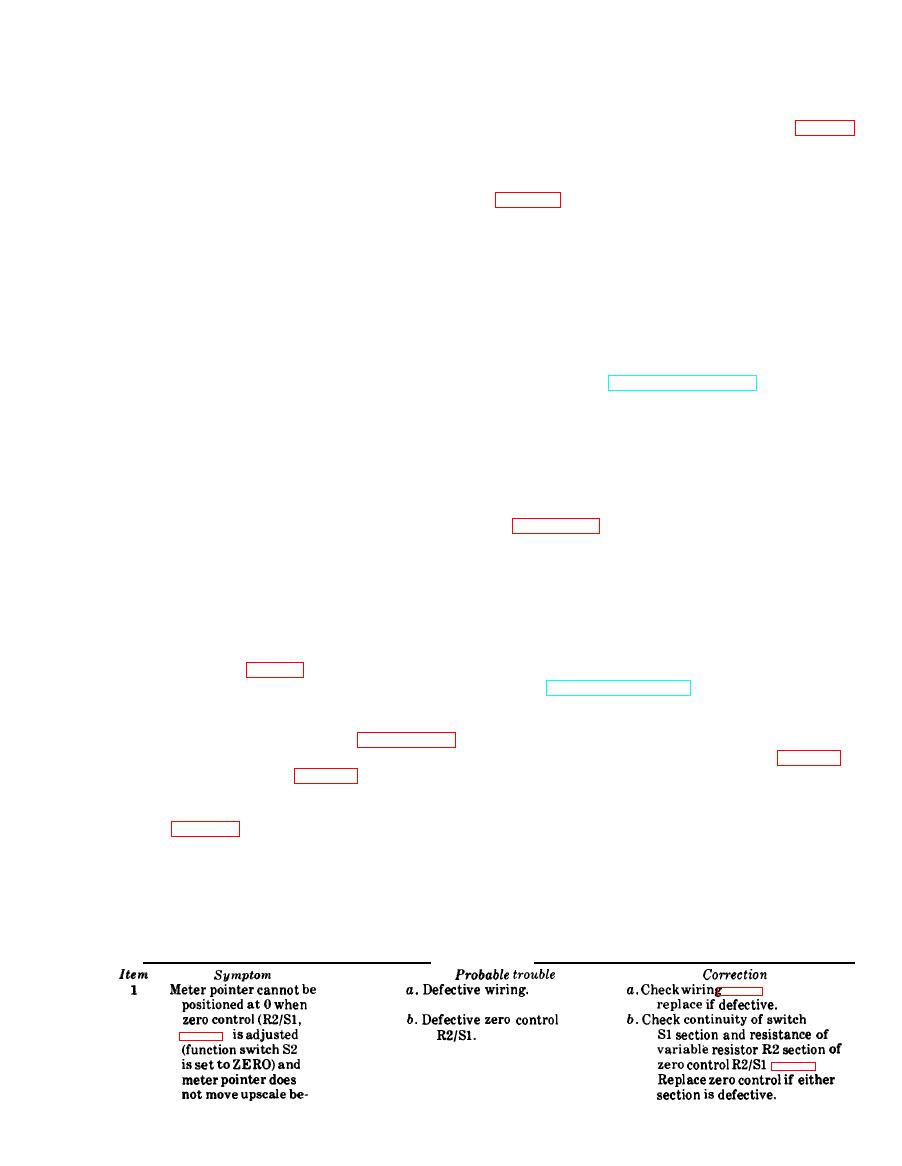

3-4. Troubleshooting Procedures

of radiation and the readings obtained are com-

pared with the known dose rates.

a. Genera/. The first step in servicing a defec-

tive readiacmeter is to localize the fault. Lo-

3-5. Troubleshooting Chart

calizing means tracing the fault to a defective

NOTE

stage or circuit responsible for the abnormal

To reach the parts of the radiacmeter,

condition. The second step is isolation. Isolation

r e m o v e the battery cover from the

means locating the defective part or parts. Some

radiacmeter (TM 11-6665-232-12), un-

faults, such as burned-out resistors, can often be

screw the small captive screws in the

located by sight and smell. The majority of the

cover assembly, and carefully remove

faults, however, must be located by checking

the cover assembly.

resistances.

a. General. In the troubleshooting chart (c be-

b. Localization. The tests listed below will aid

low), the procedures are outlined for localizing

in isolating the trouble. First localize the trou-

t r o u b l e s within the various sections of the

ble to a single circuit, and then isolate the trou-

radiacmeter. The parts locations are indicated

ble within that circuit by resistance; continuity,

in figures 3-1 through 3-4. Depending on the

and voltage measurements.

nature of the operational symptoms, one or

(1) Visual inspection. The purpose of visual

more of the localizing procedures will be neces-

inspection is to locate faults without testing or

sary. When trouble has been localized to a par-

measuring circuits. All meter readings or other

ticular portion of the radiacmeter, use voltage

visual signs should be observed and an attempt

and resistance measurements to isolate the

made to localize the fault to a particular circuit.

trouble to a particular part.

(2) Operational test. Operational tests fre-

b. Use of Chart. The troubleshooting chart is

quently indicate the general location of trouble.

designated to supplement the troubleshooting

The calibration check (para 3-3) is a good opera-

chart in TM 11-6665-232-12. If previous opera-

tional test.

tional checks have resulted in reference to a

(3) Resistance measurements. The resis-

particular Item of this chart, go direct to the

tance measurements will help locate the indi-

referenced item. If no operational symptoms are

vidual component part at fault. Figures 3-1

known, perform the calibration check (para 3-3)

through 3-4 show the location of all components.

and proceed until a symptom appears.

Use the resistor color code (fig. FO-1) to find the

c. Troubleshooting Chart.

value of the components.

NOTE

(4) Troubleshooting chart. The troubleshoot-

Replacement of parts indicated and

ing chart (para 3-5) lists symptoms of common

calibration of radiacmeter can be per-

troubles and gives (or references) corrective

formed only by depot repairmen. If a

measures.

component is replaced, the radiacmeter

(5) Intermittent trouble. In all the tests, the

must be recalibrated.

possibility of intermittent troubles should not

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |