|

|||

|

|

|||

|

Page Title:

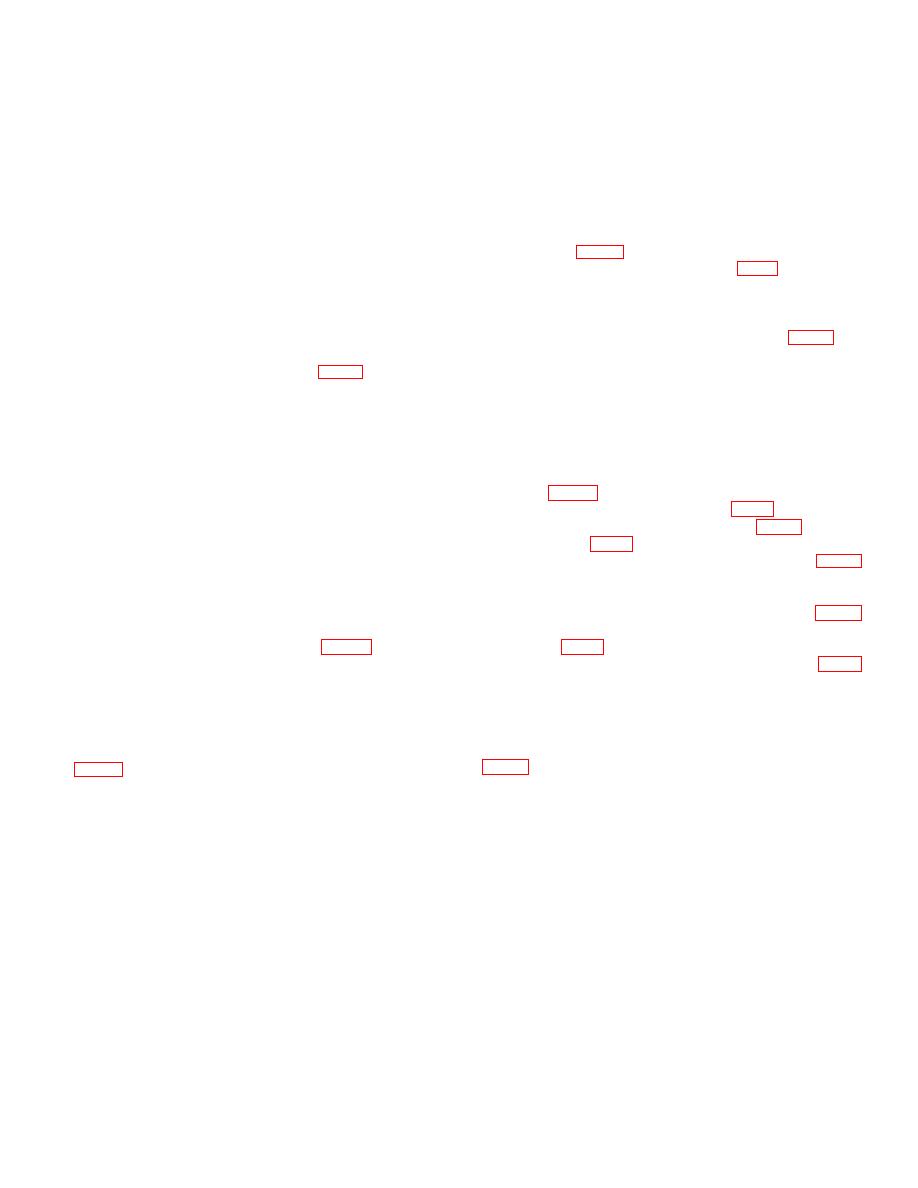

Alternate Method of Charging From Commercial Air Cylinder |

|

||

| ||||||||||

|

|

f. Charging.

(1) Close the filling line valves (3). Observe the

pressure indicated on each gage (1).

(1) Close both filling line valves (3).

With chalk, mark the pressure on each cylinder.

(2) Open the air cylinder valves (2).

(2) Close the valves on the cylinder.

(3) Determine from the pressure gages (1) which

(3) Open the filling line valves.

cylinder has the lower pressure.

(4) Bleed all rubber hoses. Disconnect the bleeder

Open the filling line valve (3) at the gage that shows the

valve assemblies from the check valves.

lower pressure. Fill the pressure tanks to the pressure

Replace the threaded caps on the check valves (7);

shown on the gage. Close the filhng line valve. Open

wrench tighten the caps.

the other filling line valve and fill the pressure tanks until

(5) Disconnect the filling lines from the cylinder

they reach at least 1,700 psi pressure.

adapters (19, fig. 2). Use two wrenches and take care

(4) When the pressure tanks are filled, close the

not to twist or kink the metal hose (4, fig. 8). Support the

filling line valves (3). Open the bleeder valves (6) on the

lines during the operation so that their full weight does

rubber hoses (5). Remove the hose fittings from the

not hang on the metal hose.

check valves (7). Screw the threaded caps onto the

(6) Remove cylinder adapters from cylinders.

check valves; wrench- tighten the caps.

g. Attaching Two Filling Lines to Four Commercial

(7) Replace the safety plug assembly (25, fig. 2).

Air Cylinders. If many pressure tanks must be charged,

(8) Replace the commercial air cylinder protection

cap.

combine the filling line assemblies (27), fig. 2) in two or

more kits for more efficient charging. An additional metal

8. Alternate Method of Charging From Commercial

hose is provided in each kit for connecting two filling line

Air Cylinder

assemblies.

When connecting two filling line

The following method can be used to charge one M2A1-

assemblies, remove one pipe plug from each assembly

7 flamethrower pressure tank, when it is removed frbm

and screw the metal hose into the openings. The

the flamethrower or riot control agent disperser:

procedure for charging is similar to the one used for two

a. Attach the filling line assembly to commercial air

cylinders (d above).

cylinders (para 7d(1) through (5)).

Air is taken first from the cylinder with the lowest

b. Cap the unused safety plug (9, fig. 9) of the filling

pressure and last from the cylinder with the highest

line assembly. Screw a tube reducer (7, fig. 3) into the

pressure.

tube reducer (3, fig. 9).

h. Proper Pressure. Insure that the air delivered to

c. Connect the bleeder valve assembly (35, fig. 2)

the flamethrower pressure tank is at a minimum of 1,700

of the 6-foot rubber hose (4) to the tube reducer (3). Be

psi pressure; 2,000 psi pressure is recommended.

sure that the bleeder valve is closed.

CAUTION

d. Unscrew the charging line adapter (33, fig. 2)

Do not overtighten the packing nut

from the other end of the rubber hose and screw a tube

reducer (9), fig. 3) into the hose.

on the filling line valve (3, fig. 8).

e. Screw a quick-disconnect coupling half (7, fig. 9)

Over- tightening can damage the

into the tube reducer (8).

packing and mating threads and

f. Attach the quick-disconnect coupling half to the

cause the valve to jam.

male quick-disconnect half on the M2A1-7 flamethrower

(1) If a filling-line valve leaks, wrench- tighten the

pressure tank.

packing nut.

g. Unscrew the metal cap from the check valve (7,

(2) When the highest pressure shown on the gage

(1, fig. 8) is less than 1,700 psi, close both cylinder

check valve with water or saliva. (Moisture prevents

valves (2) and bleed the pressure from the rubber hose

damage

to

the

rubber

wash-

by opening the bleeder valve. Close the filling line valves

(3). Remove the cylinder having the lowest pressure and

replace it with a fully charged cylinder to complete the

charging operation.

With chalk, mark the lowest

pressure on the removed cylinder.

i. After-Charging Procedure. When charging is

completed, proceed as follows:

13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |