|

|||

|

|

|||

|

Page Title:

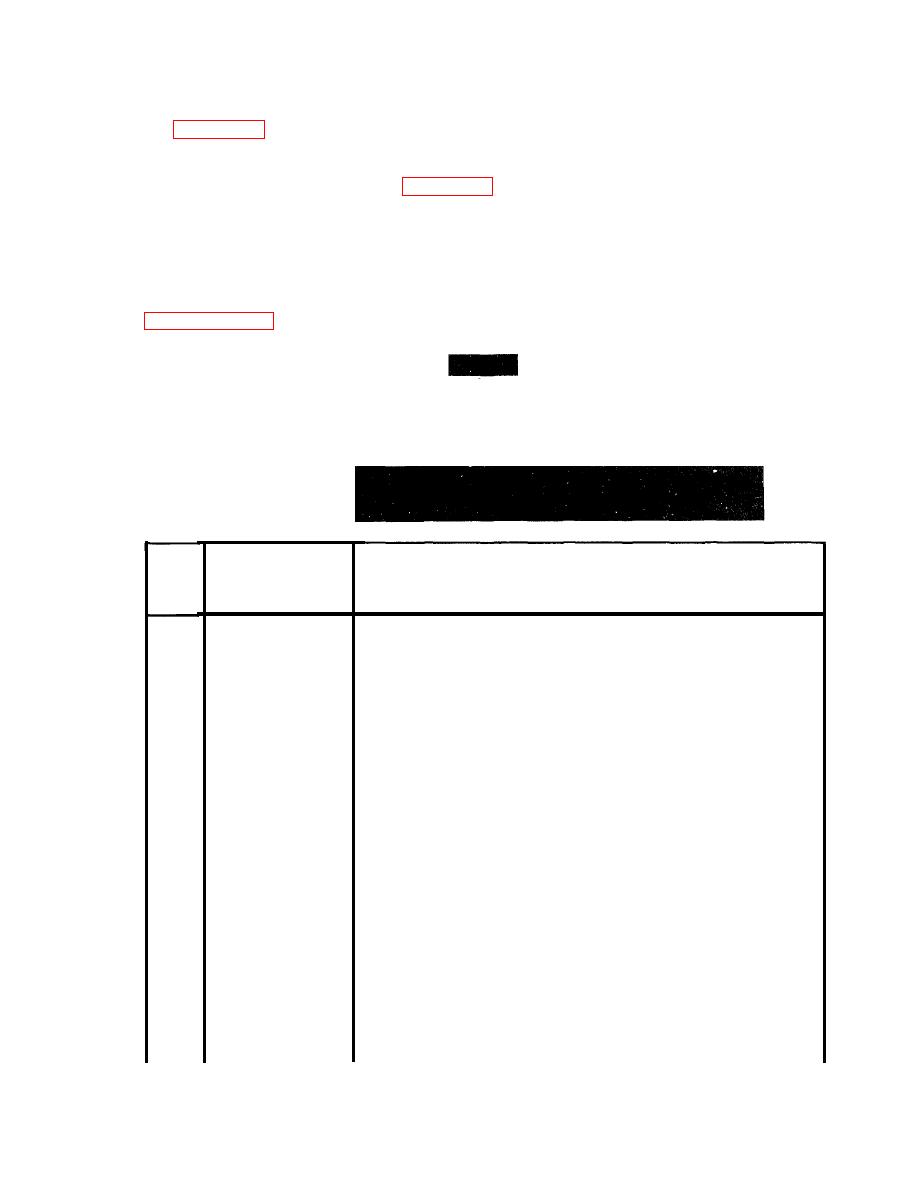

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS) |

|

||

| ||||||||||

|

|

TM 11-6665-209-20

a. Use Table 2-2 to perform preventive maintenance checks and services to be sure

that the Radiac Set is always ready for use.

b. The Item Number column in Table 2-2 should be used when making out DA Form

2404, Equipment Inspection and Maintenance Work Sheet. The item numbers in the

PMCS table go into the TM Number column on DA Form 2404.

c. The Procedures column in the table gives instructions for performing PMCS.

d. If the Radiac Set fails to operate, then follow the maintenance instructions in

paragraph 2-4 Troubleshooting.

When performing any PMCS or routine checks, keep in

mind the WARNINGS and CAUTIONS shown in this

manual.

Procedures

Item

Item to be

No.

Inspected

Painted

Check painted surfaces for missing, blistered,

1

Surfaces

or chipped paint. If surface area missing paint

is larger than one square inch, touch up painting

is required.

Inspect glass surfaces for cracks or scratches

Glass Surfaces

2

that would impair ability to obtain accurate read-

ings.

Inspect the battery compartment for corrosion.

Battery

3

Clean if necessary. Check rubber gaskets for

Compartment

wear, frays or tears, and replace if necessary.

Check for worn threads and broken or worn

Captive Screws

4

gaskets. Replace if necessary.

Range Switch

Check that the knob is not cracked or missing.

5

Check that the knob is not loose or binding. Re-

place or repair as necessary.

Check for frays, tears, or cracks in the probe and

Cables

6

headset cables.

Check for frays or tears. Check for two complete

Harness

7

clip fasteners.

Check for cracks or breaks.

Headset

8

Inspect for broken clasps or handles.

Case

9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |