|

|||

|

|

|||

|

Page Title:

Table 5. Permissible Undercut Values |

|

||

| ||||||||||

|

|

TB9-2510-242-40

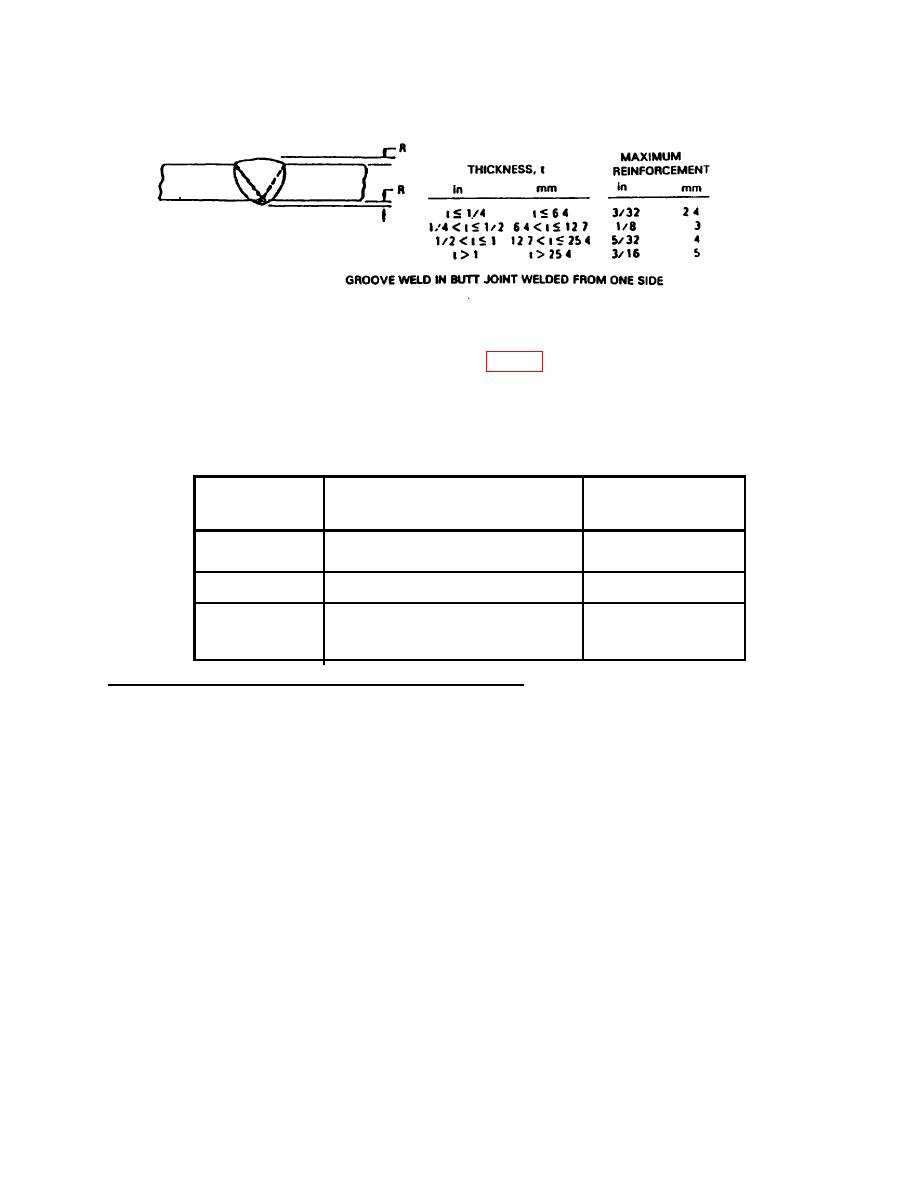

MAXIMUM REINFORCEMENT FOR A GIVEN PLATE

THICKNESS-JOINT WELDED FROM BOTH

Figure 5. Desirable Groove Weld - Cont.

f. On multi-pass welds the beads shall be wire-brushed with a degreased stainless steel brush. Brushes that have

been used to clean steel may not be re-used.

Table 5. Permissible Undercut Values

PRIMARY STRESS

MAXIMUM

THICKNESS

DIRECTION

UNDERCUT

1/8 to 1 in

Transverse

0.01 in

Over 1 in

Transverse

0.03 in

All

Parallel or none

0.03 in

4.1.9

Welding Techniques - Gas Tungsten Arc Welding (GTAW)

The following restrictions on the GTAW procedures must be observed at all times.

a. The maximum size of fillet weld made in one pass shall be no more than 1/4 inch for all positions.

b. The thickness of weld layers shall not exceed 1/4 inch. When the root opening of a groove weld exceeds 3/8

inch, a multiple pass, split layer technique shall be used. The split layer technique shall be used also when

making all multiple pass welds when the width of the layer exceeds 3/8 inch.

E-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |