|

|||

|

|

|||

|

Page Title:

Weld Profiles and Joint Requirements . |

|

||

| ||||||||||

|

|

TB9-2510-242-40

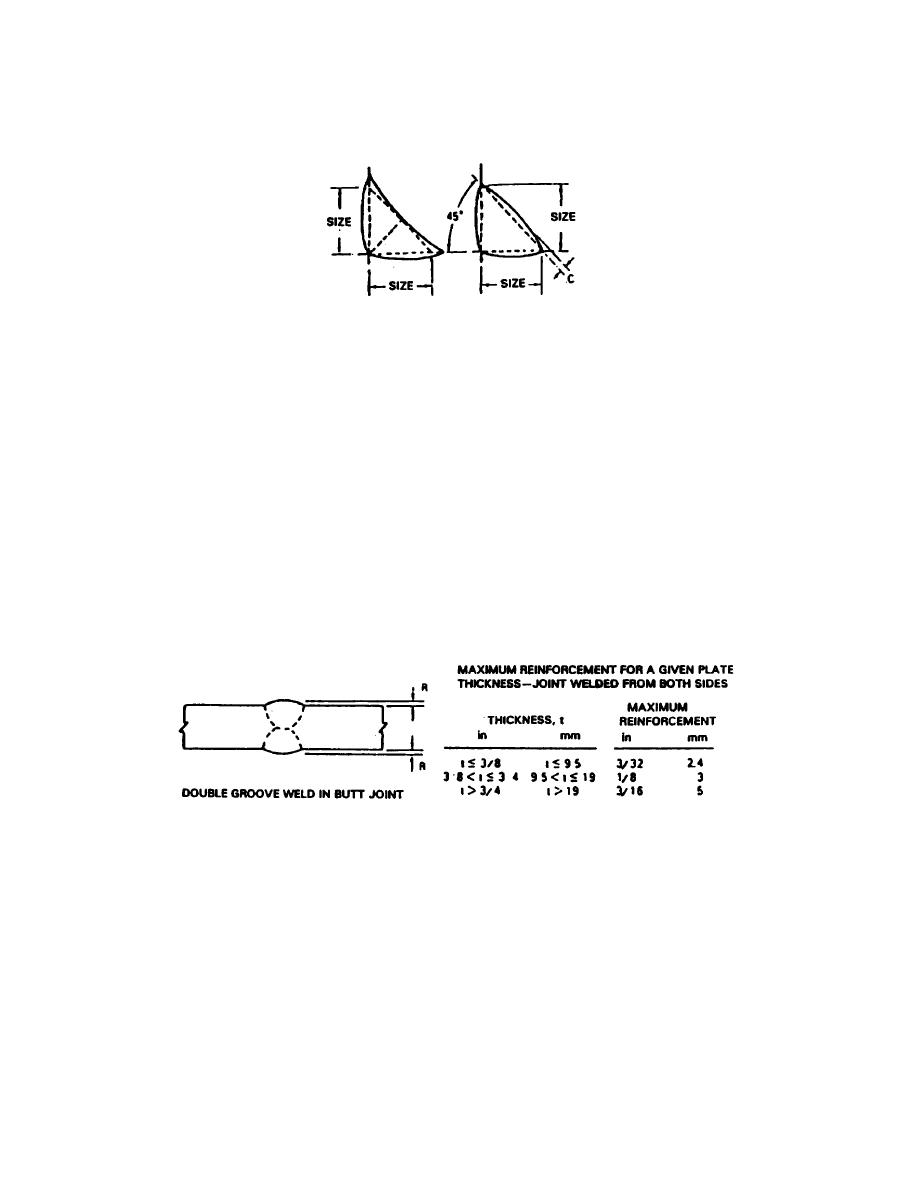

outside corner joints, the convexity ("C") of a weld or individual surface bead shall not exceed the values listed in

Figure 4, and shall have a gradual transition to the plane of the base metal surface.

NOTE: Convexity, C, of a welded or individual surface bead shall not exceed 0.057 times the actual face

width of the weld or individual bead, respectively, plus 0.06in .

Figure 4. Desirable Fillet Weld Profiles

b. Surfaces of butt joints required to be flush, shall be finished so as not to reduce the thickness of either of the

base metals or weld metal by more than 1/32 inch or 5% of thickness, whichever is smaller, or leave

reinforcement that exceeds 1/32 inch. See Figure 5 for reinforcement values.

c. All reinforcement shall blend smoothly into the plate surfaces with the transition areas free from edge weld

undercut. Where the weld forms part of a faying or contact surface, all reinforcement shall be removed.

Chipping may be used, provided it is followed by grinding or other smoothing operations. Welds shall be free

from overlap.

d. Careful joint fit-up is essential for a good quality weld. Rigid fixtures can be used to minimize distortion. Backing

bars may be used with butt welds. Tack welding may be used for ease in reassembling joints; however, tack

welds tend to be low quality and therefore should be removed as the rampis reassembled.

FIGURE 5. DESIRABLE GROOVE WELD

E-17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |