|

|||

|

|

|||

|

Page Title:

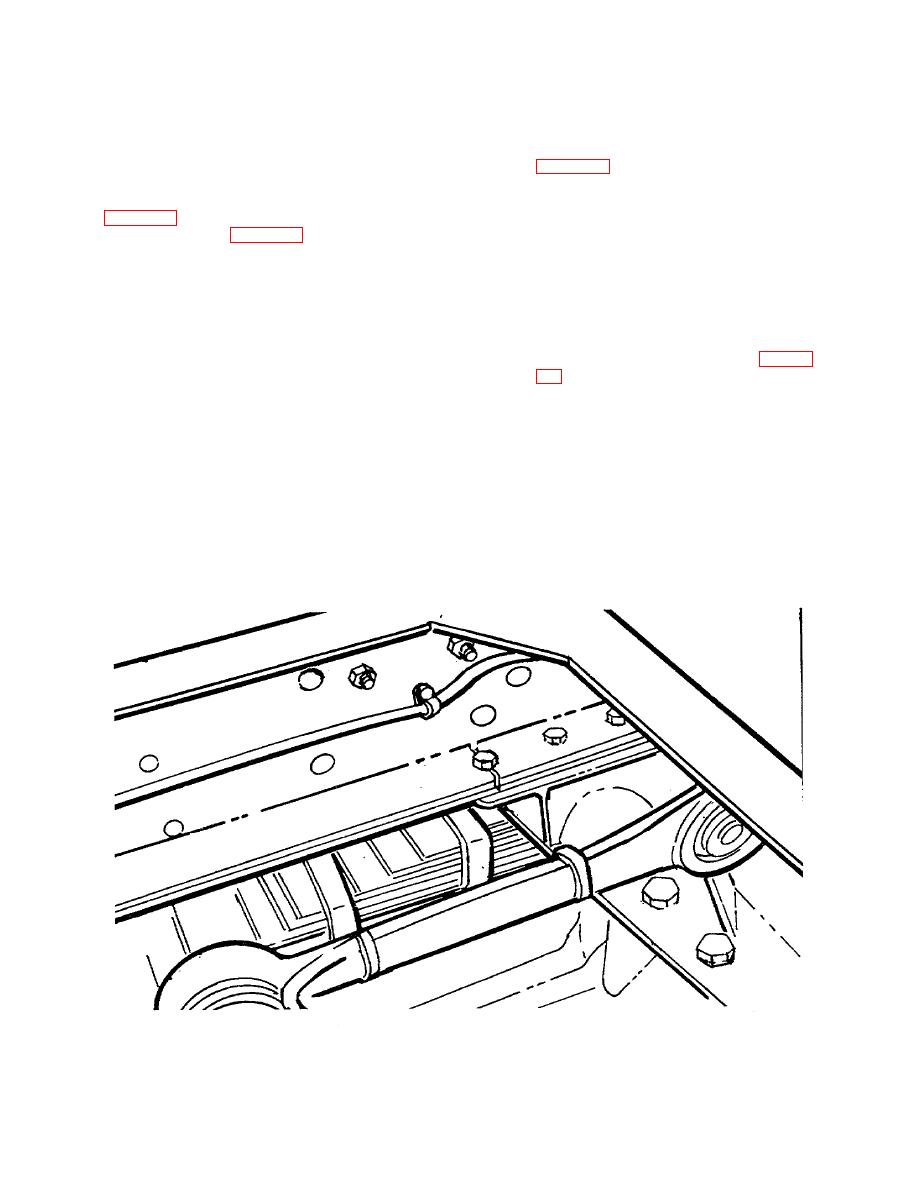

Figure 31. Crack in Lower Flange of Main Side Rail and Reinforcement Member |

|

||

| ||||||||||

|

|

TB 9-2300-247-40

l.

Drill a 3/8-inch diameter hole at the terminal of

o. Temporarily position spacer between side rail

the crack in the reinforcement member to reduce

and reinforcing member and weld reinforcement

the tendency of the crack to continue.

angle, stiffener, and filler plate as shown in

m. Fabricate reinforcement members and angles

using cold rolled steel plate as shown in

p. Remove temporary spacer and secure

reinforcement member to side rail with new No.

place as shown in Figure 29. Check carefully for

8 bolts, washers, and locknuts.

accurate fit.

NOTE

NOTE

Do not reinstall the bottom front bolt

The angle reinforcement is added

securing the bogie bracket to the rail

after the reinforcement member is in

flange at the side. The front bolt that

place. The addition of the angle is to

must be removed from all 5-ton

provide additional metal to offset the

series vehicles is identified in Figure

loss of critical metal caused by the

crack. To avoid overheating of the

hole is to remain unused as a bolt

side

rail

during

the

welding

hole.

operation, a temporary spacer must

q. Replace

all

crossmembers,

brackets,

be

provided

between

the

components/assemblies, items, anchor bolts,

reinforcement member to be welded

and other materials removed for access to the

and the side rail.

repair work, using new bolts, washers and

locknuts for all vehicle framing members.

n. Locate and drill undersized mounting holes as

shown on the sketches and ream to the exact

r.

Thoroughly clean repaired

surfaces

and

size of the new bolts to be selected.

surrounding area of repair.

Figure 31. Crack in Lower Flange of Main Side Rail and Reinforcement Member

29

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |