|

|||

|

|

|||

|

Page Title:

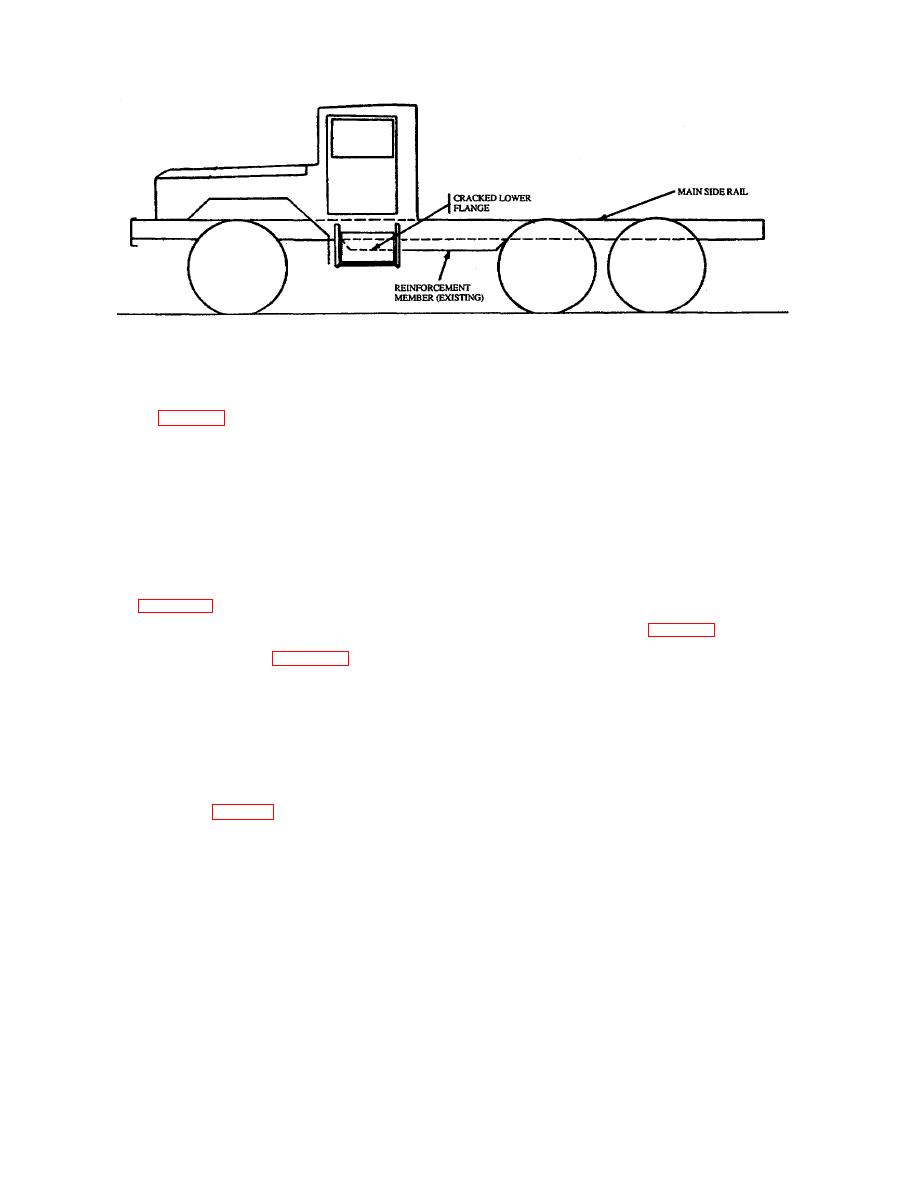

Defect. Main Side Rail Lower Flange And Reinforcing Member Failure |

|

||

| ||||||||||

|

|

TB 9-2300-247-40

Figure 29. Crack in Lower Flange of Main Side Rail Reinforcement Member

g.

Fabricate a 3/8 x 3 x 3-inch steel angle

vehicle framing members, causing

shaped to provide an accurate fit to suit the

the metal adjacent to the weld to be

reinforcing member under repair as shown

weakened.

As a result of the

in figure 31 h. Clamp the steel angle into

destructive properties of welding on

position and bolt as indicated.

heat-treated steel, welding of heat-

treated 5-ton truck framing members

i.

Thoroughly clean repaired surfaces and

is prohibited except as otherwise

surrounding area of repair.

specified. This repair can best be

accomplished by plates secured with

j.

Prime and paint repair area and

bolts, locknuts, and washers.

surrounding surfaces as specified in TM-

43-0139.

c.

Remove the rear axle suspension

bracket, rubber bumper bracket,

k.

Verify frame alignment as specified in

and remove the crossmembers,

removing all rivets and bolts as

specified in Section I.

48.

Defect. Main Side Rail Lower Flange And

d.

Slightly deflect the side rail on the side of

failure in the lower flange of the main side rail and

the cracked crossmember.

reinforcing member approximately 12 or 13 inches

forward of the centerline of the rear axle assembly.

e.

Detach the cracked reinforcement member

from the cracked side only.

a. Thoroughly clean vehicle frame of all oil,

grease, dirt, and debris.

f.

Carefully jack up the rear of the vehicle

frame at four locations to evenly distribute

b. Perform general vehicle frame inspection as

the load and to reduce the stress at the

specified in Section I.

point of the frame defect.

NOTE

g.

Perform the necessary removal of

Heat-treated steel frames, such as

components, service lines, electrical wiring,

those used in 5-ton trucks are

etc., as required to gain access to the

assembled using bolts and rivets.

proposed repair.

Most welding processes destroy the

heat treatment properties of the

27

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |