|

|||

|

|

|||

|

Page Title:

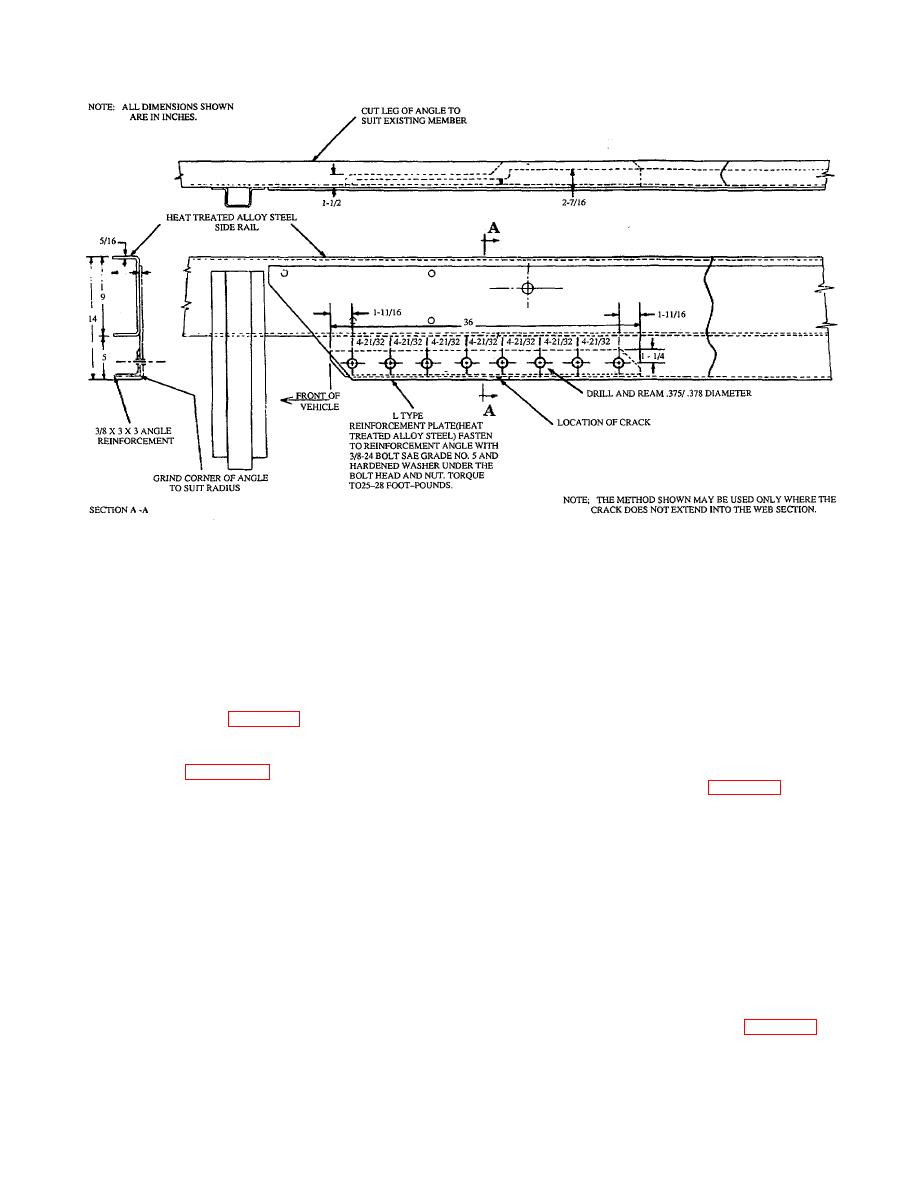

Figure 30. Reinforcement Angle for 5-Ton Truck Frame |

|

||

| ||||||||||

|

|

TB 9-2300-247-40

Figure 30. Reinforcement Angle for 5-Ton Truck Frame

NOTE

WARNING

The rear axle suspension bracket

Use only effective chip guarding

located below the lower flange of the

equipment, protective equipment and

main side member prevents the

protective clothing (goggles, shields,

adding of reinforcement plates in this

gloves aprons, etc.) when doing any

area. However, reinforcements may

drilling, grinding, or welding. Failure

be located in the area within the

to follow this warning could result in

channel (refer to Figure 29 ).

injury to personnel.

(1) Remove bolts and rivets securing

Fabricate the reinforcing member as

brackets or other items to the frame

shown in Figure 31. The metal is

as described in Chapter 1.

being added primarily to the lower

flange. This is the principal area

(2) For tractors, remove fifth wheel anchor

where the additional support is

bolts, as required.

needed. Because metal cannot be

welded to the main side rail, the full

(3) For cargo trucks, remove cargo body

design load cannot be supported.

brackets, anchor bolts, and raise body

The metal to provide design load

for clearance.

support must be added to the

reinforcing member by welding,

j.

Using jack, deflect side rail member

using low carbon steel.

outward a distance of not more than

1/2-inch at the rear crossmember.

h.

Remove rear axle suspension bracket,

bumper bracket, on the cracked side of the

k.

Remove

defective

reinforcement

frame only.

member as shown in Figure 28.

i.

Remove

the

following

components/

assemblies as required for accessibility:

28

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |