|

|||

|

|

|||

|

Page Title:

CHAPTER 4 FRAME REPAIR PROCEDURES |

|

||

| ||||||||||

|

|

TB 9-2300-247-40

CHAPTER 4

FRAME REPAIR PROCEDURES

SECTION I. 3/4 TO 1-1/4 TON SERIES VEHICLE FRAMES

(2) Rear shock absorber shaft attachment

to side rail

38.

General.

(3) Inner and outer side rail joints, both top

a.

Types of repairs. Common types of frame

and bottom, between the front engine

failure repairs which can be performed on

support

and

the

number

2

the CUCV and HMMMV (3/4 to 1-1/4-ton

crossmember.

series) vehicles are; (1) Inadequate or

broken welds and (2) cracked side rails, top

(4) Steer gear bracket to the side rail

and bottom flanges and the frame vertical

frame structure.

web.

(5) Vertical weld between the front engine

CAUTION

mount bracket and its support bracket,

riveted to the inner side rail.

Welding is not an approved or

acceptable alternate method of repair

(6) Vertical weld between the end

for any riveted or bolted attachment

brackets

on

the

number

2

(e.g. crossmember, spring hanger

crossmember and the inner side rail.

etc.) on the CUCV vehicle series

39.

Cleaning and Painting.

frame assembly.

a.

Thoroughly clean vehicle frame of all oil,

b.

Welding Instructions. Welding instructions

grease, dirt, and debris.

described in Section I will be followed to

repair broken welds in the following areas

b.

Prime and paint repair area and

of this vehicle series frame:

surrounding surfaces as specified in TM-

43-0139.

(1) Front spring hangar brackets to side

rail.

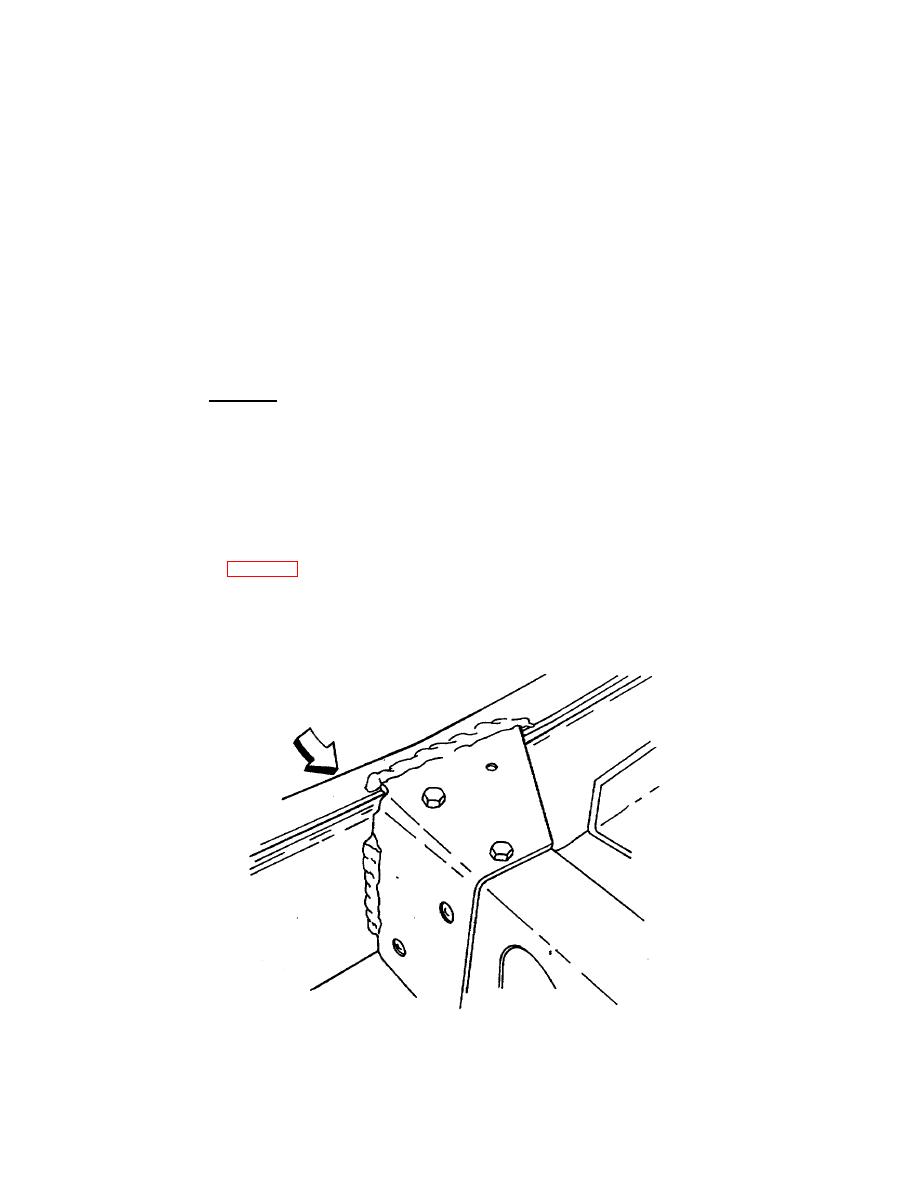

Figure 18. Cracked Side Rail Outer Flange

18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |