|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

SB 740-95-20

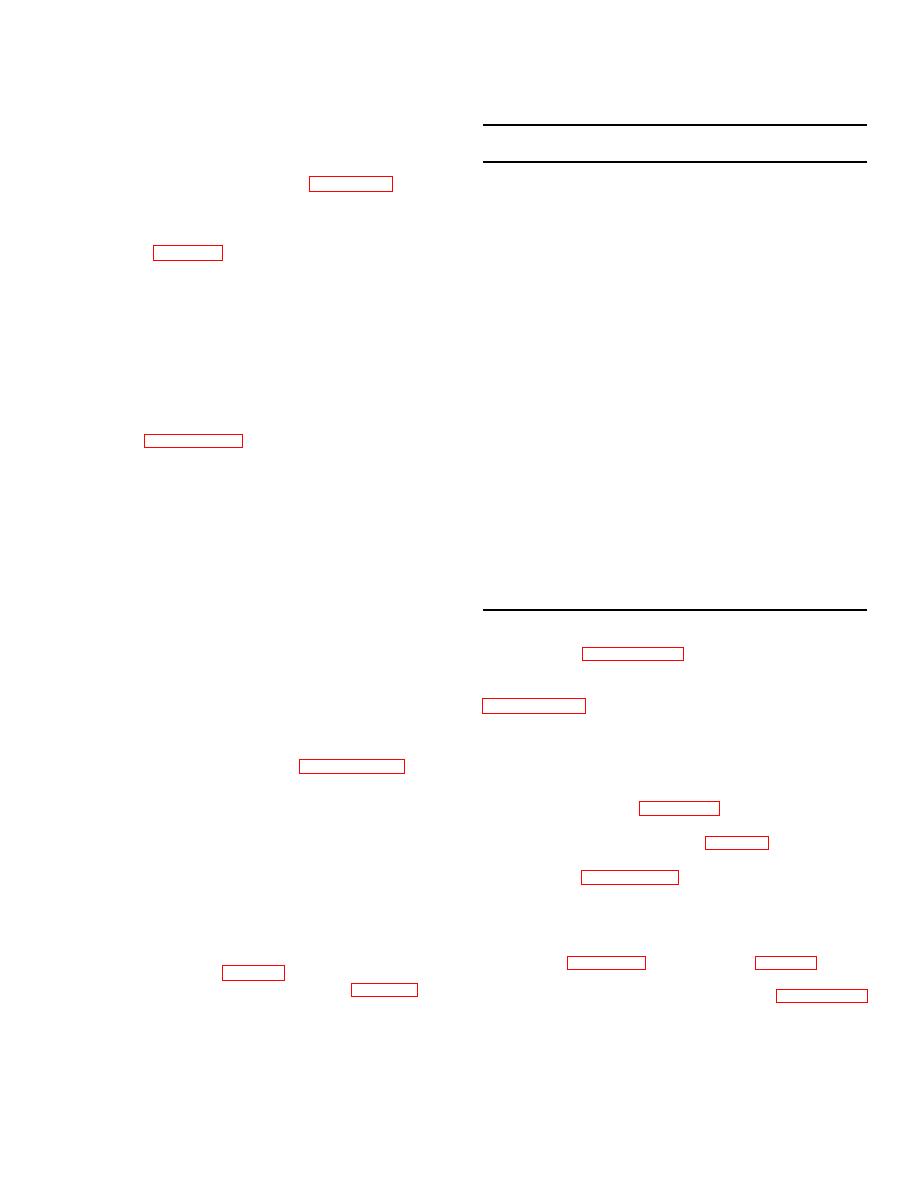

Table 2-1. Initial Receipt Inspection (IRI) or

General Inspection Level II, and AQL of 4.0 percent for

Prestorage Inspection (PSI)

Major Defectives, and an AQL of 10.0 percent for Minor

Defectives.

Defect

Inspection

c. Cyclical Inspection (CI). Sampling shall be

Category Number

Defect

Method

conducted by this paragraph and MIL-STD-105 using the

Critical:

None defined.

Inspection Level and AQL specified in appendix A or the

Major:

sampling instructions provided in the applicable appendix

101

Item damaged.

Visual

(TRC) of this bulletin for the item being sampled.

102

Packaging, packing, or

Visual

d. Pre-Issue Inspection (PII).

Sampling, if

preservation damaged

required, (see para 2-5d(2)) shall be conducted by c

or deteriorated to the

above.

extent that adequate

e. Selection of Samples.

protection is no longer

(1) All portions of the lot must be located for

afforded to the item

sampling.

or handling and

(2) Every reasonable effort must be made to

storing would be ad-

obtain a random sample. When conditions make a

versely affected.

proper random sampling impossible, record this fact and

103

Item packaging or pack-

Visual

a brief description of the condition that prevents random

ing contaminated,

sampling under the remarks section Part I, Block 20, of

wet, or mildewed as a

the DA Form 984, 1 Jun 80, Munitions Surveillance

result of adverse ship-

Report. See paragraph 2-9a(1), Part I (t), of this bulletin.

ping conditions.

(3) In selecting samples from depot lots,

104

Packaging, packing,

Visual

grand lots, or miscellaneous lots, choose the items to

marking, or preserva-

represent all materiel. For example, if a manufacture's

tion incorrect.

lot is one-third of the total lot, then select one-third of the

Minor:

lot sample at random from that manufacturer's lot.

201

Slight damage to

Visual

f.

Sample Disposition.

packaging, packing.

(1) In the inspection records, identify as

or preservation but

reinspected, all samples that have been inspected and

not affecting the pro-

then packed and resealed in barrier material.

tection.

(2) Reseal barrier material using the

instructions furnished with the material, on the material,

(3) Reporting. Use DA Form 984 and the

or with the sealing iron.

instructions in paragraph 2-9. In addition, report failure

(3) Return serviceable samples to storage

data and discrepancies encountered on SF 368 (Quality

with the parent lot.

Deficiency Report), in accordance with AR 702-7. See

(4) Segregate samples with critical or major

defects or samples that cannot be returned to the original

b. Prestorage Inspection (PSI).

package configuration and report such in the remarks

(1) Frequency. Perform this inspection on

section, Part II, Block 13, of DA Form 984, 1 Jun 80,

an occurrence basis.

Munitions Surveillance Report. See paragraph 2-9a(1),

(2) Examination and test.

When the

Part II (h) of this bulletin.

serviceability status is unknown, perform the examination

2-5. Inspection. Conduct all inspections and tests

and test of the item by appendix A instructions, including

under the control of a qualified inspector (see para 1-

any applicable appendix (TRC) of this bulletin. Examine

3b(12)). The inspections and tests normally will be

all lots for receipt condition using table 2-1.

conducted at the surveillance inspection area; however,

(3) Reporting. Use DA Form 984 and the

when authorized, examinations or tests may be

instructions in paragraph 2-9.

performed at the storage site or elsewhere, but must be

c. Cyclical Inspection (CI).

within the limitations of all safety and security

(1) Frequency. The inspection frequencies

requirements.

for given types of storage and given types of packing

a. Initial Receipt Inspection (IRI).

based on the Army Master Data File (AMDF) are

(1) Frequency. Perform this inspection on

contained in appendix B by the IFC (see para 2-6e).

(2) Examination and test.

Perform the

(2) Classification of defects. Use table 2-1 to

examinations and tests of the item by appendix A

evaluate the incoming materiel.

instructions including any applicable appendix (TRC) of

this bulletin.

2-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |