|

|||

|

|

|||

|

Page Title:

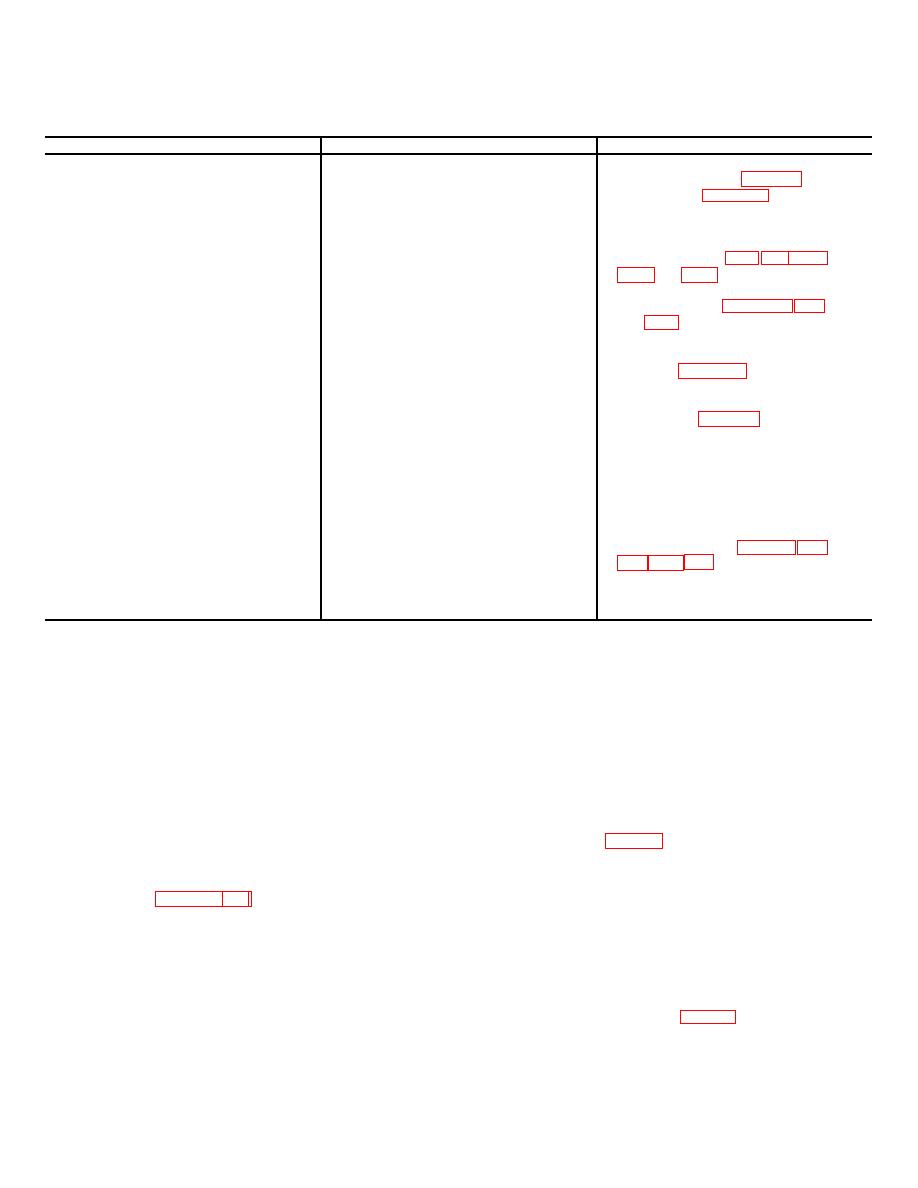

Chart 3-1. Troubleshooting-Direct Support |

|

||

| ||||||||||

|

|

TM 5-4310-340-24

Chart 3-1. Troubleshooting-Direct Support

Malfunction

Probable Cause

Corrective Action

1. Compressor overheats.

a. Defective fan spring.

b. Defective fan.

c. Replace compressor (TM-9-2350-

components

232-20-1).

2. Relief valve activated (open).

a. Defective cooler to next higher

a. Replace defective cooler and/or

stage and/or defective af-

tercooler.

b. Defective relief valve.

b. Test relief valve by replacement

with a new valve (para 3-12. 3-1

and 3-17). Discard relief valve

removed if defective.

3. Excessive oil consumption.

a. Defective oil seals and/or

a. Replace defective seals and/or

packings.

packings (para 3-26).

b. Excessive worn internal corn-

b. Replace compressor (TM 9-2350-

ponents.

232-20-1).

4. Excessive vibration.

a. Defective fan.

b. Defective compressor.

b. Replace compressor (TM 9-2350-

232-20-1).

5. Compressor

a. Defective spline (input shaft).

a. Replace compressor (TM 9-2350-

232-20-1).

b. Replace compressor (TM 9-2350-

components.

232-20-1).

6. Insufficient air pressure in system.

a. Leaking cooler or cooler con-

a. Tighten connection or replace

nection.

cooler as required (para 1-5, 3-8,

b. Defective relief valve.

b. See item 2b.

c. Defective compressor.

c. Replace compressor (TM 9-2350-

232-20-1).

Section IIl. REMOVAL AND INSTALLATION OF MAJOR COMPONENTS

3-4. General

CAUTION

The information this section provides direct and general

support maintenance personnel with the necessary

Cap or plug all openings, after removal of

instructions to remove and install all compressor assembly

components or subassemblies from compressor,

major components and assemblies as allocated by the

in order to prevent entry of dirt into unit. Entry of

maintenance allocation chart. Removal and installation of a

dirt into unit can result in damage or malfunction

component or an assembly does not require the removal of all

of equipment.

preceding components

in the disassembly sequence.

Remove only those items necessary to permit -access to the

3-5. Fan Guard

defective components being removed. During installation of

a. Removal (fig C-3).

Remove four screws (10),

pipe threaded fittings use teflon tape. per MIL-T-27730 at

lockwashers (9), washers (8) and fan guard (7) from brackets

threads and lubricate-thread-and packings with oil per M1L-L-

(26).

23699., Torque components as specified in the assembly

b. Installation. Position fan guard (7) on brackets (26)

instructions and paragraph 1-5.

with cutaway at bottom of compressor. Aline bracket screw

holes between fan guard parallel traverse bars. Secure fan

WARNING

guard to brackets with four washers (8), lockwashers (9), and

Do not attempt to remove

or disassemble

screws (10).

pressurized equipment. Stop all equipment

operation, vent all pressure to atmosphere prior

3-6. Fan and Fan Spring

to performing work in order to prevent injury to

WARNING

personnel and damage to equipment.

Remove fan spring (18, fig C-3) with extreme

care. The spring is spring loaded and will recoil

suddenly when removed causing possible injury

to personnel.

3-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |