|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

3208 INDUSTRAIL AND MARINE ENGINES

DISASSEMBLY AND ASSEMLBLY

FLYWHEEL

REMOVE FLYWHEEL

11-1156

Tools Needed

A

FT120

Lifting Bracket

1

S609

Bolt

1

start by:

a) remove marine gear (marine engine only)

1.

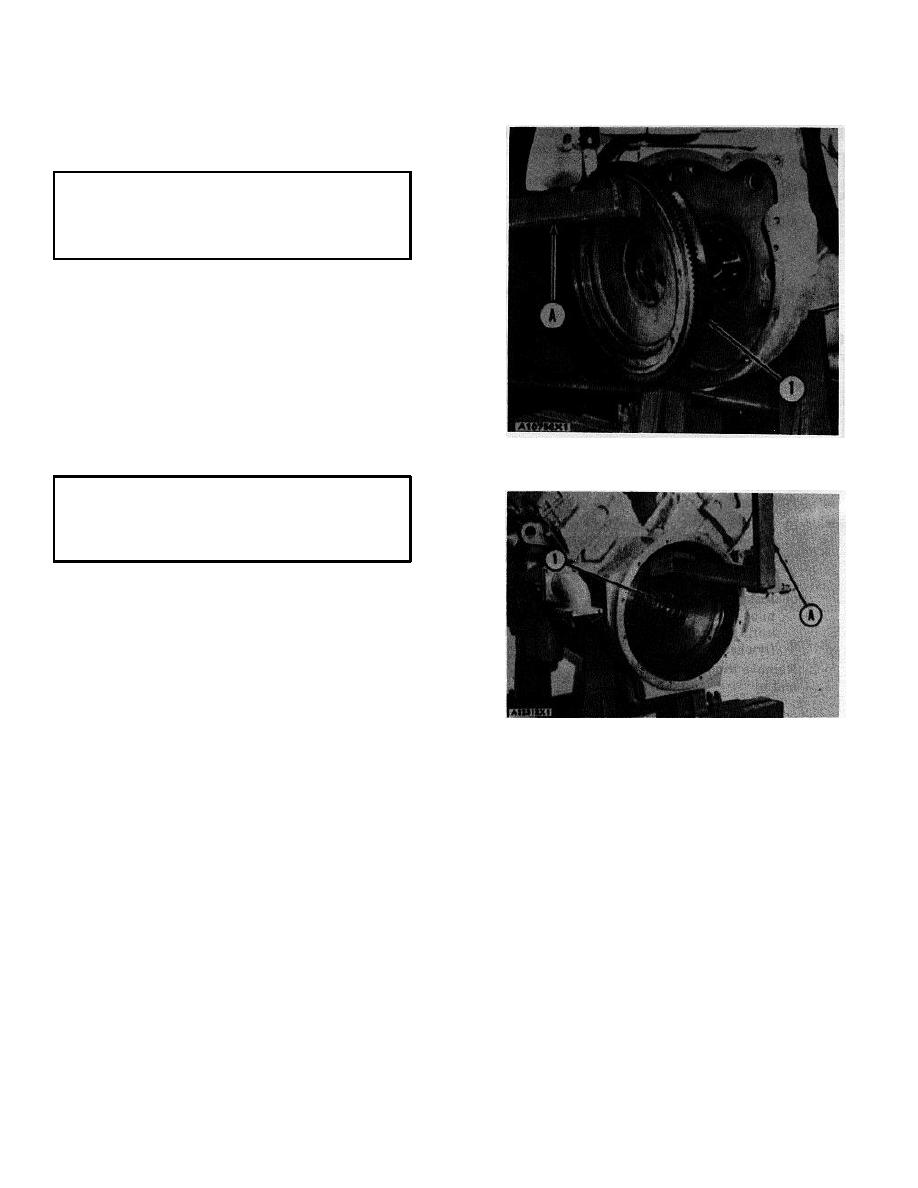

Install tooling (A) on the flywheel.

Fasten a

hoist to tooling (A).

2.

Remove the bolts that hold the flywheel in

place. Remove flywheel (1). The weight of the

flywheel is 68 lb. (31 kg).

INSTALL FLYWHEEL

12-1156

MARINE ENGINE SHOWN

Tools Needed

A

FT120

Lifting Bracket

1

S509

Bolt

1

1.

Install tooling (A) on the flywheel, Fasten a

hoist and put the flywheel in position on the

crankshaft. Make sure the marks on the

flywheel and crankshaft are in alignment.

2.

Put 8H5137 Gasket Sealer on the bolt threads

and install bolts (1). Tighten the bolts to a

torque of 55 5 lb. ft. (7.6 0.7 mkg).

NOTE: Make sure that the correct sealant is put on the

INDUSTRIAL ENGINE SHOWN

bolt threads. The holes for the bolts in the crankshaft

flange are drilled through making the holes open to the

oil in the engine. Leaking along the bolt threads can be

the result if the correct sealant is not used.

CAUTION: When installing a new flywheel, check the

thickness of the new flywheel at the bolt holes in relation

to the thickness of the old flywheel. Install the correct

length bolts so they will be fully engaged in the

crankshaft flange. Bolts that are too long will make

contact with the block on back side of the crankshaft

flange and pull crankshaft back. This will cause the

crankshaft thrust bearing to fail.

end by:

a)

install marine gear (marine engine only)

89

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |