|

|||

|

|

|||

|

Page Title:

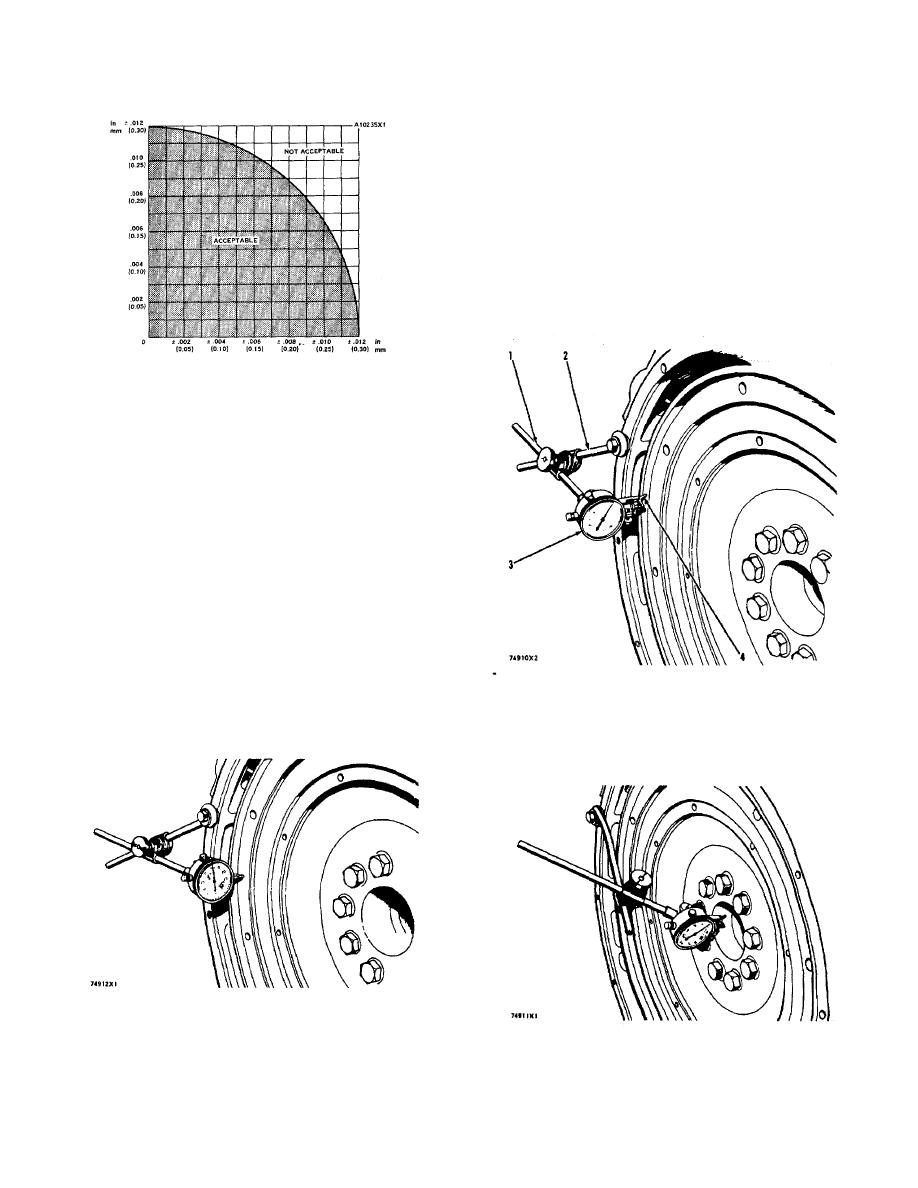

Face Run out (axial eccentricity) of the Flywheel |

|

||

| ||||||||||

|

|

BASIC BLOCK

TESTING AND ADJUSTING

3. Turn the flywheel and read the indicator every 90

.

4. The difference between the lower and higher

measurements taken at all four points must not be

more than .006 in. (0.15 mm), which is the maximum

permissible face runout (axial eccentricity) of the

flywheel.

Bore Runout (radial eccentricity) of the Flywheel

1. Install the dial indicator (3) and make an adjustment of

the universal attachment (4) so it makes contact as

shown.

GRAPH FOR TOTAL ECCENTRICITY

10. If the point of intersection is in the range marked

"Acceptable" the bore is in alignment. If the point of

intersection is in the range marked "Not Acceptable"

do Step 11.

II.

Loosen the bolts holding the flywheel housing to the

cylinder block. Hit the flywheel housing lightly with a

hammer to put it in the correct position. Tighten the

bolts holding the flywheel housing to the cylinder

block and do Steps 1 through 10 again.

Face Runout (axial eccentricity) of the Flywheel

1. Install the dial indicator as shown. Force the crankshaft

the same way before the indicator is read so the

crankshaft end clearance (movement) is always

removed.

CHECKING BORE RUNOUT OF THE FLYWHEEL

2. Set the dial indicator to read .000 in. (0.0 mm).

1. 7H1945 Holding Rod. 2. 7H1645 Holding Rod. 3,

7H1942 Indicator. 4. 7H1940 Universal Attachment.

CHECKING FACE RUNOUT OF THE FLYWHEEL

CHECKING FLYWHEEL CLUTCH

PILOT BEARING BORE

80

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |