|

|||

|

|

|||

|

Page Title:

Bore Run out (radial eccentricity) of the Flywheel Housing |

|

||

| ||||||||||

|

|

BASIC BLOCK

TESTING AND ADJUSTING

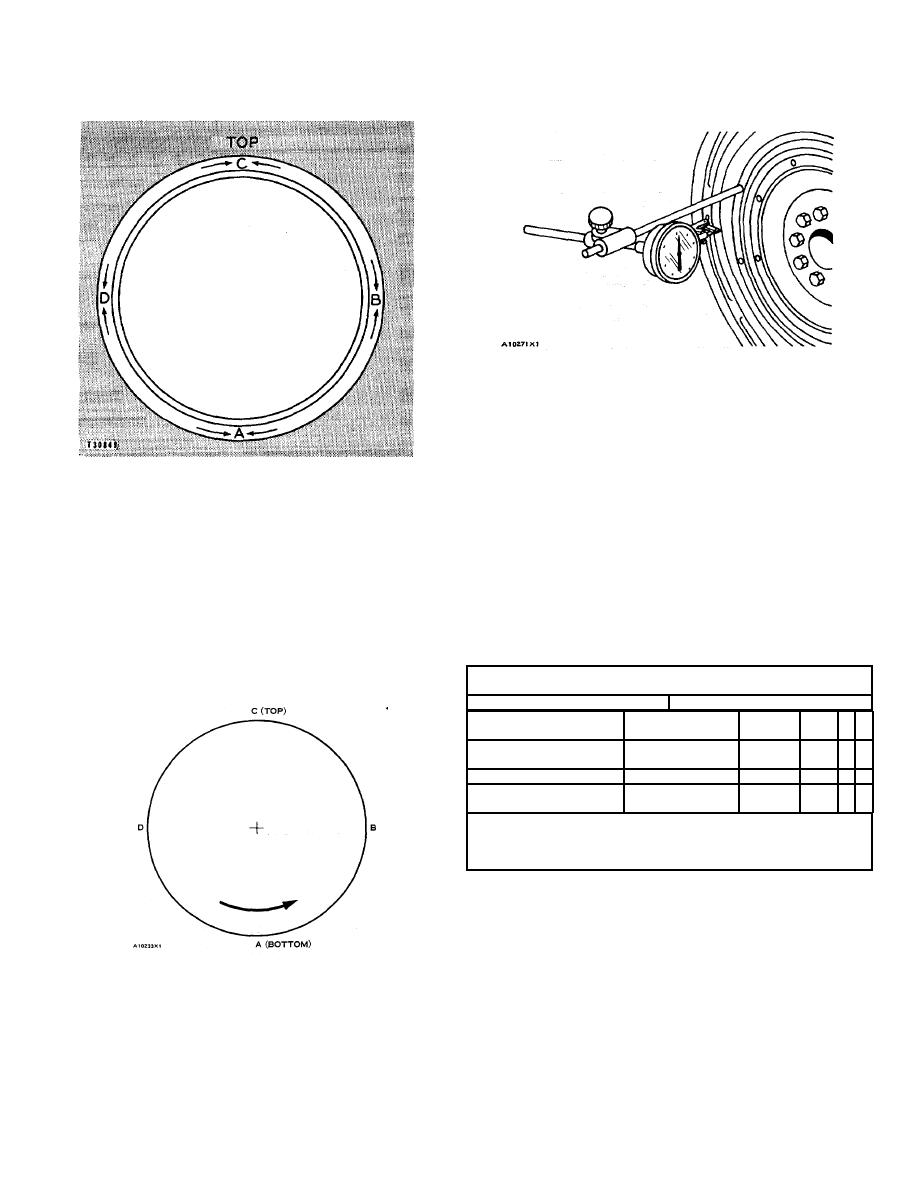

8S2328 DIAL INDICATOR GROUP INSTALLED

2. Divide the measurement from Step 1 by 2. Write this

number on line I in columns (B) & (D).

3. Turn the crankshaft to put the dial indicator at (A).

Adjust the dial indicator to "0" (zero).

4. Turn the crankshaft counterclockwise to put the dial

CHECKING FACE RUNOUT OF THE

indicator at (B). Write the measurement in the chart.

FLYWHEEL HOUSING

5. Turn the crankshaft counterclockwise to put the dial

A. Bottom. B. Right side. C. Top. D. Left side.

indicator at (C). Write the measurement in the chart.

6. Turn the crankshaft counterclockwise to put the dial

indicator at (D). Write the measurement in the chart.

Bore Runout (radial eccentricity) of the Flywheel

7. Add lines I & II by columns.

Housing

8. Subtract the smaller number from the larger number

in line III in columns (B) & (D). The result is the

1. With the dial indicator in position at (C), ad- just the

horizontal "eccentricity" (out of round). Line III,

dial indicator to "0" (zero). Push the crankshaft up

column (C) is the vertical eccentricity.

against the top bearing. Write the measurement for

bearing clearance on line 1 in column (C).

CHART FOR DIAL INDICATOR MEASUREMENTS

Position of dial indicator

Line No

A

B

CD

Correction for bearing

I

0

clearance

Dial Indicator Reading

II

0

Total of Line 1 & 2

III

0

**

*

*

*

*Total Vertical eccentricity (out of round).

**Subtract the smaller No. from the larger No. The

difference is the total horizontal eccentricity. A0234X1

9. On the graph for total eccentricity find the point of

intersection of the lines for vertical eccentricity and

horizontal eccentricity.

CHECKING BORE RUNOUT OF THE

FLYWHEEL HOUSING

79

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |