|

|||

|

|

|||

|

Page Title:

High-Pressure Tube Repair - Using Hose and Union. |

|

||

| ||||||||||

|

|

TM 5-3835-222-BD

g. Operate ail hydraulic subsystems (except those that may still be damaged) to remove air from

the system. Check carefully for fluid leaks. Tighten leaking fittings.

h. Check the hydraulic reservoir again to ensure a sufficient hydraulic fluid level. If this level is

low, refer to para 8-13 and fill the reervoir as needed.

i. Record the BDAR action taken. When the mission is completed, as soon as practicable,

repair using standard maintenance procedures.

8-7.5. High-Pressure Tube Repair - Using Hose and Union.

Limitations:

High-pressure hose must be used for high-pressure repair.

Personnel/Time Required:

1 soldier - 1.5 hrs.

Materials/Tools:

Tool Kit

Hose Fitting(s) (Female)

Hose, Hydraulic, High-Pressure

Hex Union

Tube Fitting(s), Female, Flareless

Tape

Saw

Vise

Procedural Steps:

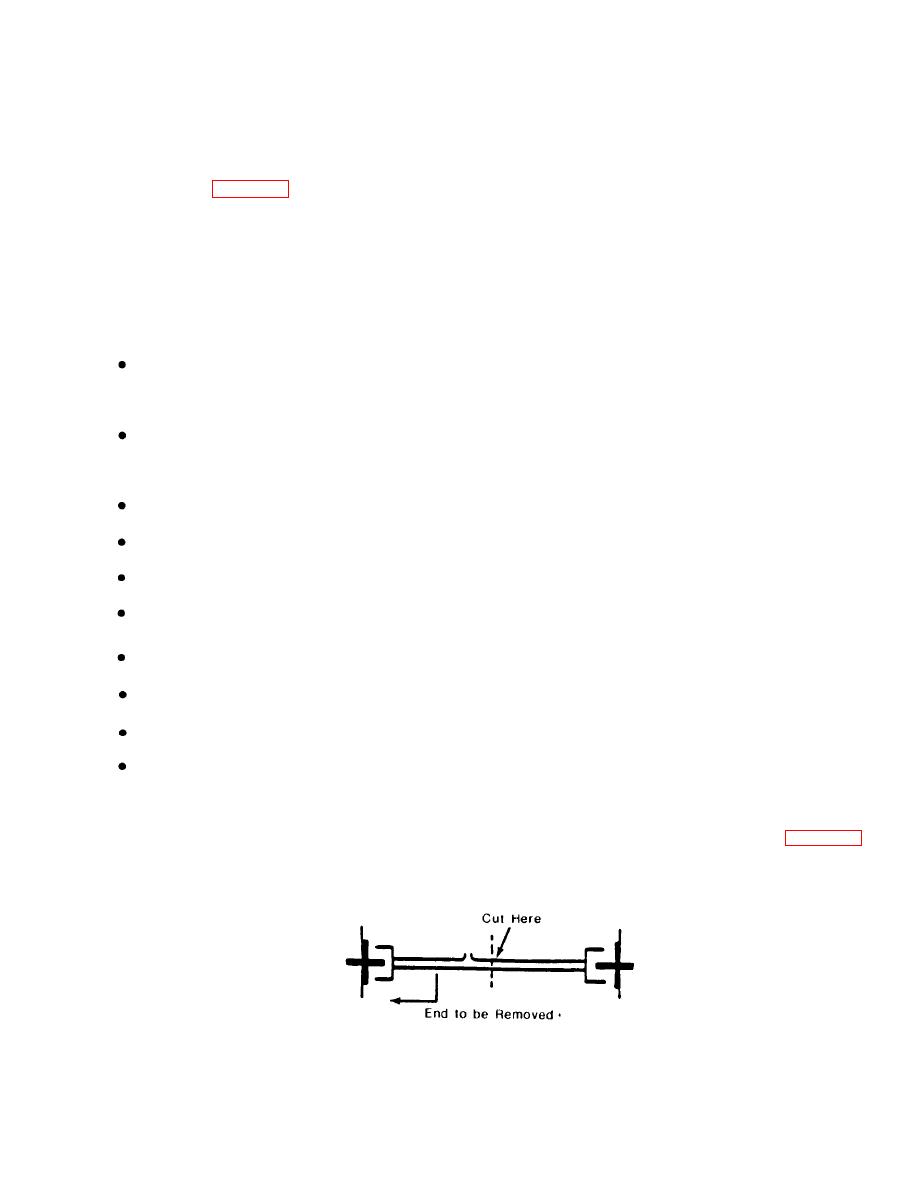

a. Squarely cut off the damaged section of the tube that will be replaced by the hose (see para 8-17).

Remove the tube to be replaced.

8-17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |