|

|||

|

|

|||

|

Page Title:

ORGANIZATIONAL PREVENTIVE MAINTENANCE CHECKS AND SERVICES SCHEDULE (CONT) |

|

||

| ||||||||||

|

|

TM 3-1040-276-23

ORGANIZATIONAL PREVENTIVE MAINTENANCE CHECKS AND SERVICES SCHEDULE (CONT)

M - MONTHLY

S - SEMIANNUALLY

Interval

Item

Item

To Be

No.

M

Procedures

Inspected

S

3

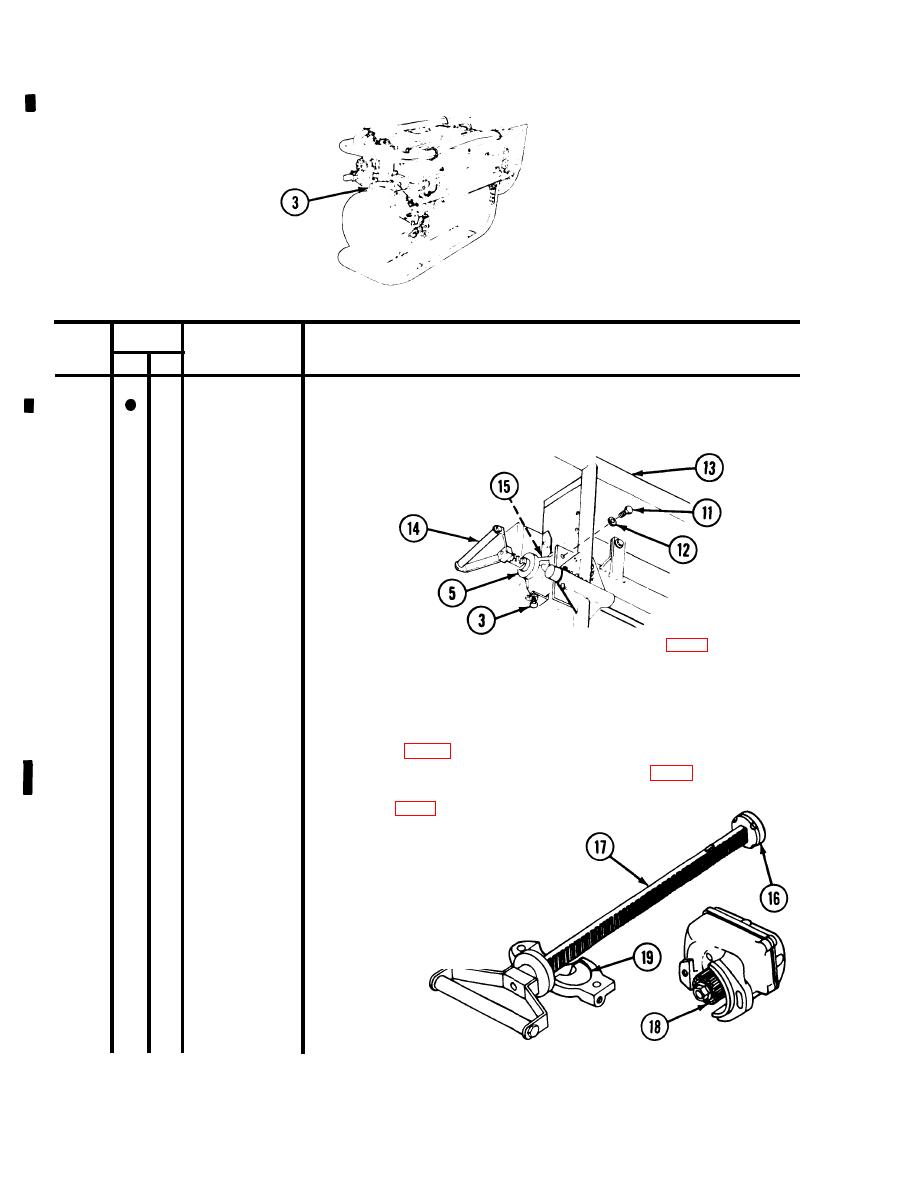

e. Remove cap screw (11) and washer (12) from frame (13) and clamp (5).

Magneto air

pump

f.

Pull air pump handle (14) and remove clamp (5) with assembled items

assembly

from magneto air pump tube (15).

(cont)

g. Clean dirty parts with dry cleaning solvent (item 4, app C).

h. Check plunger (16) for cuts, brittleness, or deterioration.

i. Check for bent rack (17) and broken rack teeth.

j. Check for broken teeth on gear (18) and check if gear turns easily.

k. Disassemble, clean, inspect, repair, replace, and reassemble parts as

required (p 2-51).

l.

Fill grease cup (19) with aircraft grease (item 5, app C), and lubricate

inside of magneto air pump tube and plunger (16) with lubricating oil

(item 6, app C).

CAUTION

When inserting plunger (16) into

magneto air pump tube (15),

carefully guide plunger past

edges of groove opening in tube.

Forcing plunger against the

edges will cut or tear

the plunger.

2-6

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |