|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

b. Cleaning and Lubricating.

(1) Clean the removed serviceable parts if

required.

(2) Clean the valve body cavity.

(3) Before installing the trigger, apply silicon

lubricant to the trigger cavity.

c. Assembly and Installation

(1) If the trigger safety has been removed,

perform the following:

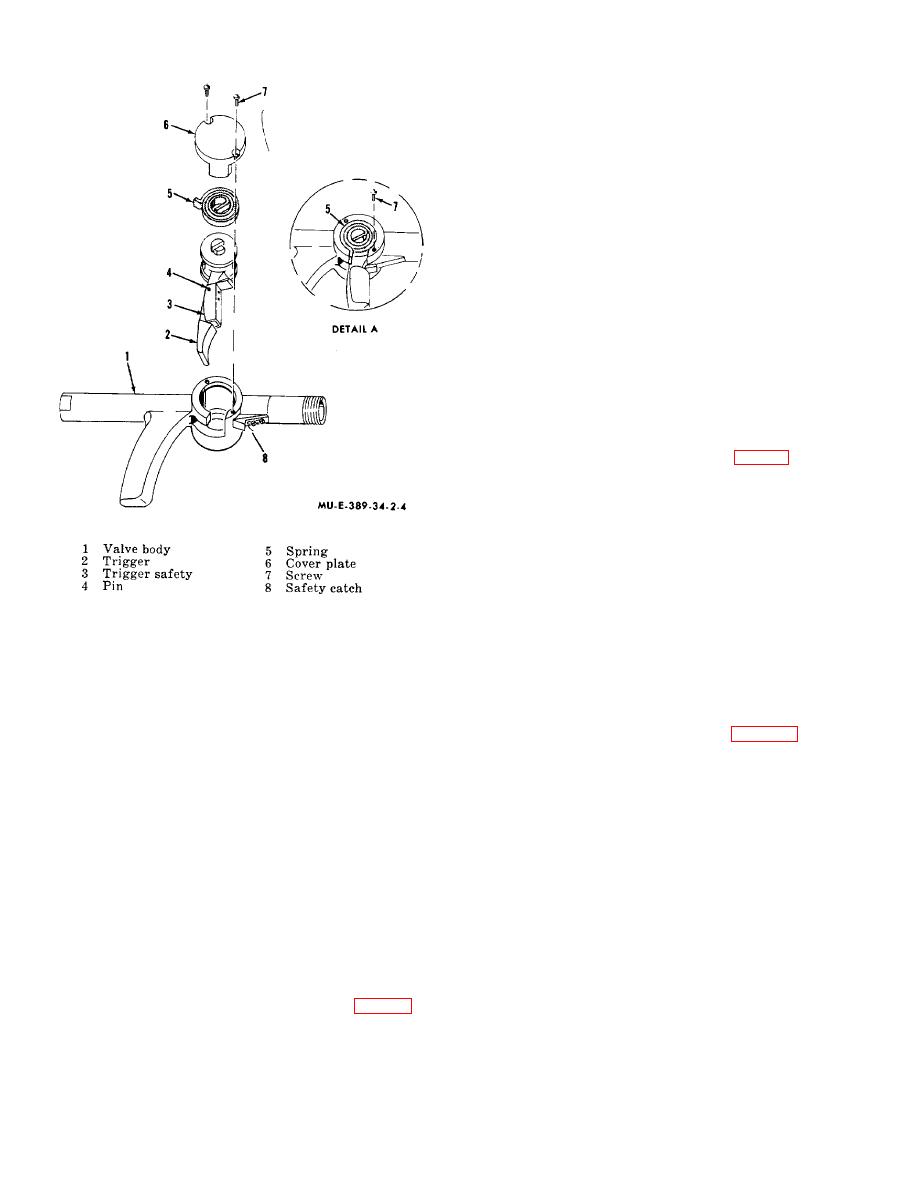

(a) Place the trigger safety (3) on the

trigger (2).

(b) Install the pin (4) to secure the trigger

safety (3) to the trigger (2).

(c) Apply silicon lubricant on the trigger.

(2) Install the trigger (2) in the valve body cavity.

(3) Position the trigger safety (3) so that it

engages the safety catch (8).

(4) Place the spring (5) on top of the trigger (2).

The center of the spring should be engaged in the slot in

the trigger shaft as shown in detail A, fig. 2-4.

WARNING

The spring must be installed under

tension.

Care must be exercised

when in- stalling the spring.

(5) Install temporarily a screw (7) as shown in

Figure 2-4. Trigger and safety assembly.

detail A.

(6) With a pair of pliers, squeeze the ex- tended

Care must be exercised when removing

end of the spring (5) and temporarily in- stall screw (7)

the spring.

until the extended end of the spring is seated properly in

(3) Remove the spring (5) and trigger (2) from

the valve body cavity.

the valve body cavity.

(7) Remove screw (7, detail A).

(4) If the trigger safety must be replaced perform

(8) Install the cover plate (6) and two screws (7).

the following:

(9) Install the removed parts (para 2-1b).

(a) Remove the pin (4).

(b) Remove the trigger safety (3) from

the trigger (2).

Section II. PRESSURE SECTION

(2) Disconnect the coupling nut (12) from the

2-3. Valve Shaft Assembly

pressure tank valve (17).

(3) Remove the wing nut (11), eyelet (7), and

Direct support maintenance personnel are authorized to

clamp (10).

replace the valve handle, clamp, eye- let, and coupling

(4) Remove the nut (8) and handle (9).

nut.

b. Inspection.

a. Removal.

(1) Inspect the removed parts, including the

(1) Close the pressure tank valve (17, fig. 2-5) by

coupling nut (12) and valve shaft (6), for possible

turning the handle (9) clockwise.

damage. Check especially the threads on the nut.

(2) Replace unserviceable parts.

2-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |