|

|||

|

|

|||

|

Page Title:

Pressure Regulator and Safety Valve |

|

||

| ||||||||||

|

|

TM 3-1040-214-12

(3) Install valve handle (9) and nut (10).

Tighten nut.

(4) Slide clamp (7) on valve shaft.

(5) Install pressure tank and valve assembly

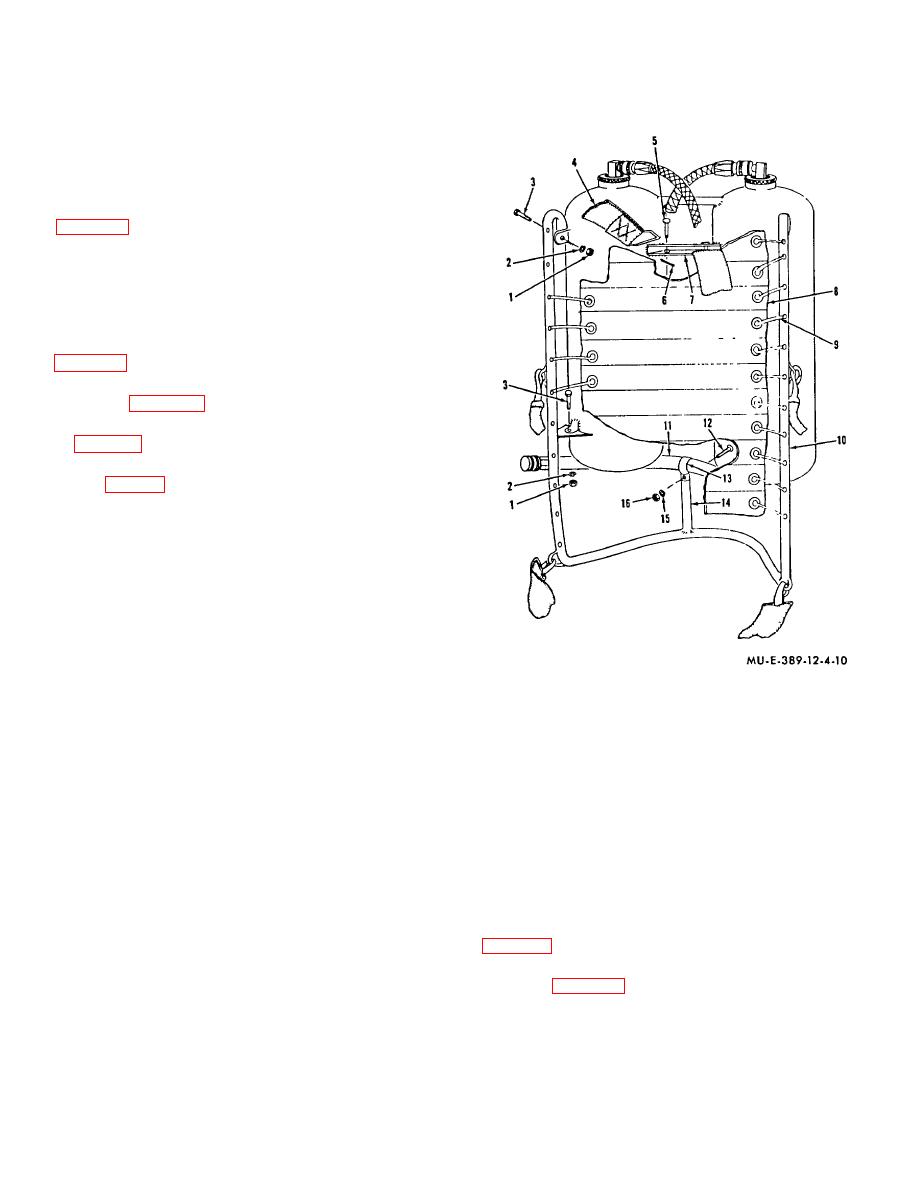

4-32. Pressure Regulator and Safety Valve

Organizational maintenance personnel are authorized to

replace the pressure regulator and safety valve.

a. Removal.

(1) Purge the air in the air pressure system

(para 4-10a).

(2) Remove the pressure tank and valve

assembly. (para 4-10b).

(3) Unlace one side of the carrier pack

(8, Fig. 4-10).

(4) Disconnect the quick-disconnect coupling

half (3, Fig. 4-5) from the pipe and cap assembly (4).

NOTE

Hold

pressure

regulator

when

performing next step.

(5) Unscrew diffusion tube nut (8) from safety

valve adapter (9).

(6) Unscrew safety valve adapter (9) from

safety valve (11).

(7) If required, remove the tube assembly (16)

from the pressure regulator (18).

1

Nut

9

Cord

(8) If required, remove the quick-disconnect

2

Washer

10

Frame

coupling half (f5) from the tube assembly (16).

3

Screw

11

Agent delivery pipe

4

Upper strap assembly

12

Screw

b. Installation.

5

Pin

13

Clamp

(1) Apply anti-seize compound or tape to the

6

Cotter pin

14

Support

tube assembly (16) exterior threads.

7

Bracket

15

Washer

8

Carrier pack

16

Nut

(2) Connect the quick-disconnect coupling

half (15) to the tube assembly and tighten.

Figure 4-10. Carrier Section.

(3) Install loosely the tube assembly (16) to

(7) Tighten tube assembly (16)

to

inlet

the inlet adapter (17).

adapter (17).

(4) Install lead washer (10) on safety valve

(8) Cross the disconnected hose assemblies

(11). Connect safety valve (11) to adapter (9).

(2) and connect the quick-disconnect coupling half (3) to

(5) Align diffusion tube (5) with safety valve

opposite pipe and cap assemblies as shown in

adapter (9).

Check to see that quick-disconnect

coupling half (15) on tube assembly is centered between

(9) Install the

pressure

tank

and

valve

both agent tanks.

assembly (para 4-10c).

(6) Tighten nut (8).

4-33. Safety Head

Organizational maintenance personnel are authorized to

replace the washer and the safety head.

4-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |