|

|||

|

|

|||

|

Page Title:

CHAPTER 3 OPERATOR'S MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

TM 3-1040-214-12

CHAPTER 3

OPERATOR'S MAINTENANCE INSTRUCTIONS

Section I. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

Report equipment defects to organizational maintenance

3-1. General

The preventive-maintenance checks and services (table

personnel.

services which must be performed at the intervals

3-2. Explanation of Columns

prescribed. Use the list to make sure that all required

A number under before or after-operation in the "Interval

maintenance is accomplished. If corrective action is not

and sequence No." column indicates that the services

authorized at operator's level, do not use the equipment.

opposite the number must be performed in numerical

sequence at the prescribed time.

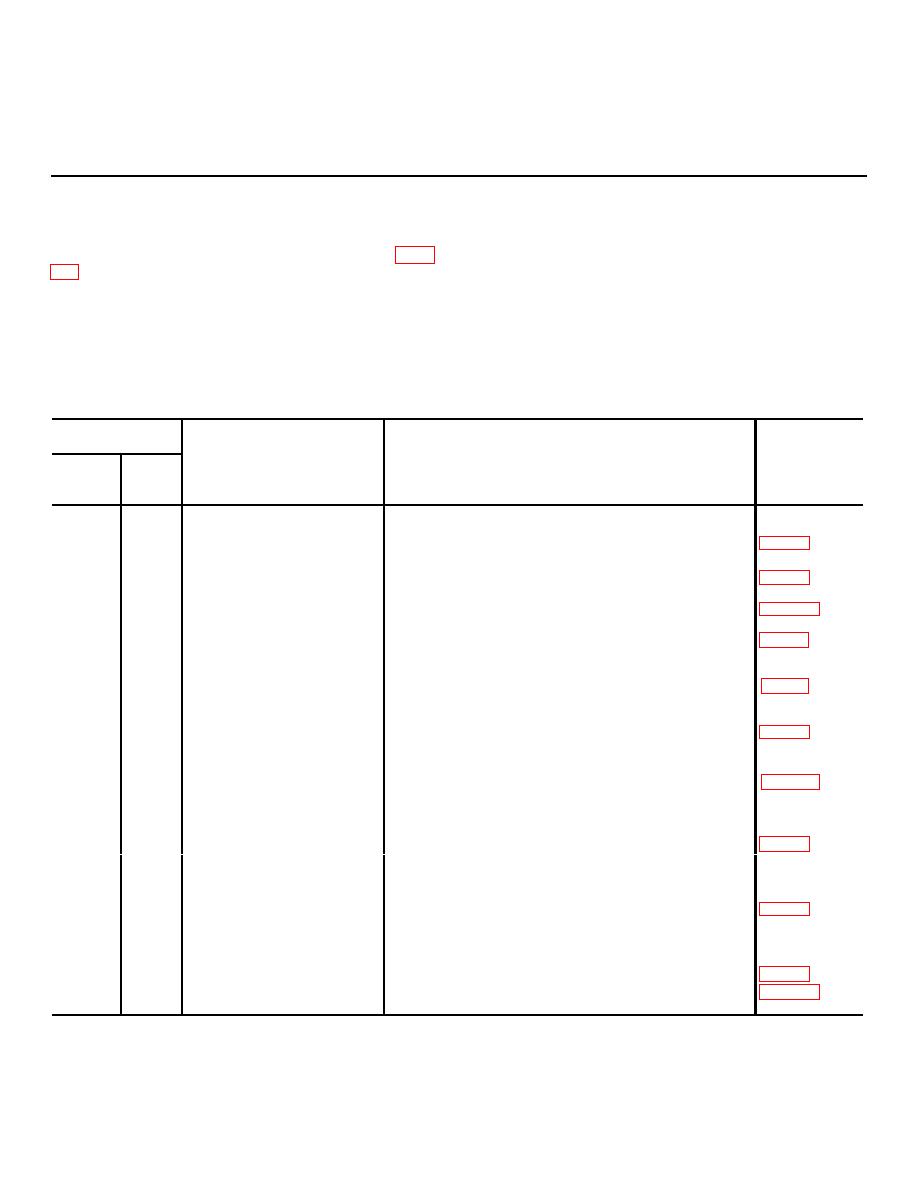

Table 3-1. Preventive Maintenance Checks and Services Operator's Maintenance Category

Interval and

sequence No.

Item to be inspected

Procedure

Reference

Before-

After-

opera-

opera-

tion

tion

AGENT SECTION

1

-----

Pipe and cap assembly ----------- Check to see that pipe and cap assemblies are net loose.

Handtighten knurled tank caps.

2

-----

Hose assemblies and quick-

Check to see that hose quick-disconnect coupling half

disconnect coupling half.

operates properly.

3

-----

Agent tanks -------------------------- Check the hydrostatic and volumetric test date on the

agent tanks.

4

-----

Hinged clamp and wingnut------ Check hinged tank clamp and wingnut. See that pressure

-

tank is secured properly.

5

10

Shutoff valve ------------------------- Check to see that the shutoff valve is closed -------------------

PRESSURE SECTION

6

-----

Pressure tank, valve assem-

a. Check to see that the valve shaft is secured prop-

bly, valve handle, and

erly with clamp and wingnut. Check valve handle

valve shaft.

and valve shaft for possible damage.

b . Check that the volumetric test date on the pressure

tank.

CARRIER SECTION

7

11

Strap assemblies, carrier

Check for damaged webbing and cotton cord. Check for

pack, frame, and attach-

missing cord and damaged straps and hardware.

ing hardware.

HOSE GROUP

8

-----

Hose assembly---------------------- Check to see that gun and hose are attached to tank

group.

GUN GROUP

9

12

Gun assembly, trigger, trig-

Check operation of trigger and trigger safety--------------------

ger safety, and rubber

tube.

3-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |