|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TROUBLESHOOTING

c. Isolation. The checks listed below will

aid in isolating the trouble. After the trouble

Troubleshooting at fourth and fifth echelon

has been isolated to a particular circuit, isolate

maintenance levels includes all the techniques

the trouble within that circuit to a particular

outlined for organizational maintenance (TM

part.

11-6625-274-12) and any special or additional

(1) Resistance measurements. Use the

techniques required to isolate a defective part.

schematic diagram (fig. 42-44) to find

The field and depot maintenance procedures are

the value of the components. Use re-

not complete in themselves but are supple-

sistance measurements (para 17 and

mented by the procedures described in TM 11-

6625-274-12. The systematic troubleshooting

normal readings, and compare them

procedure, which begins with the checks that

with the readings taken.

can be performed at an organizational level,

(2) Troubleshooting chart. The symptoms

must be completed by means of additional lo-

listed in the troubleshooting chart

calizing and isolating techniques.

to a component part.

(3) Intermit tent troubles. In all these

a. General. The first step in servicing a de-

tests, the possibility of intermittent

fective test set is to localize the fault to the

troubles should not be overlooked. If

circuit responsible for abnormal operation. The

present, this type of trouble may often

second step is to isolate the fault to the defec-

be made to appear by tapping or jar-

tive part that is responsible for the abnormal

ring the equipment. Check the wiring

condition. Some faults, such as a burned-out

and connections to the test set.

resistor, can often be located by sight or smell.

The majority of faults, however, must be local-

ized by checking resistances.

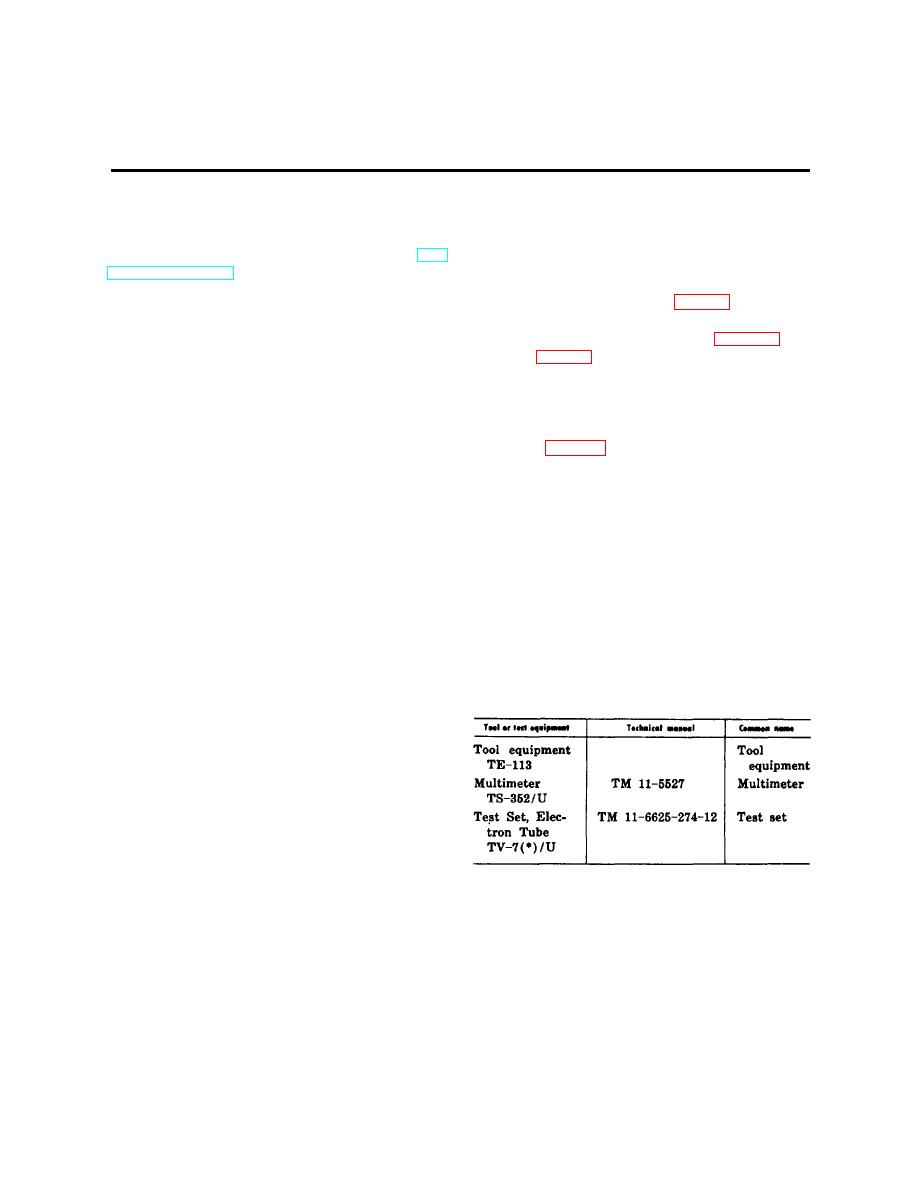

The following chart lists the tools and test

b. Localization. The test set can be used

equipment required for troubleshooting the test

to check pilot lamps, diode tubes, amplifier

set, the associated technical manuals, and the

tubes for Gm, gas, and noise, and to check tubes

assigned common names.

for shorts. The first step in localizing troubles

is to determine the circuit or circuits at fault

by the following methods:

(1) Visual inspection. The purpose of

visual inspection is to locate faults

without testing or measuring circuits.

All meter readings and other visual

signs should be observed to try to

localize the fault to a particular cir-

cuit.

a. General. In the troubleshooting chart

(2) Operational tests. Operational tests

frequently indicate the general loca-

(c below), procedures are outlined for isolat-

ing troubles to. a particular component part.

tion of trouble. In many instances,

the tests will help in determining the

The adjustment chart (d below) indicates the

exact nature of the fault. The equip-

test that is to be performed when certain com-

ment performance checklist (TM 11-

ponent parts are adjusted or replaced. Parts

6625-274-12) is a good operational

locations for the different models of the test

test.

set are shown in figures 15 through 32. Re-

20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |