|

|||

|

|

|||

|

Page Title:

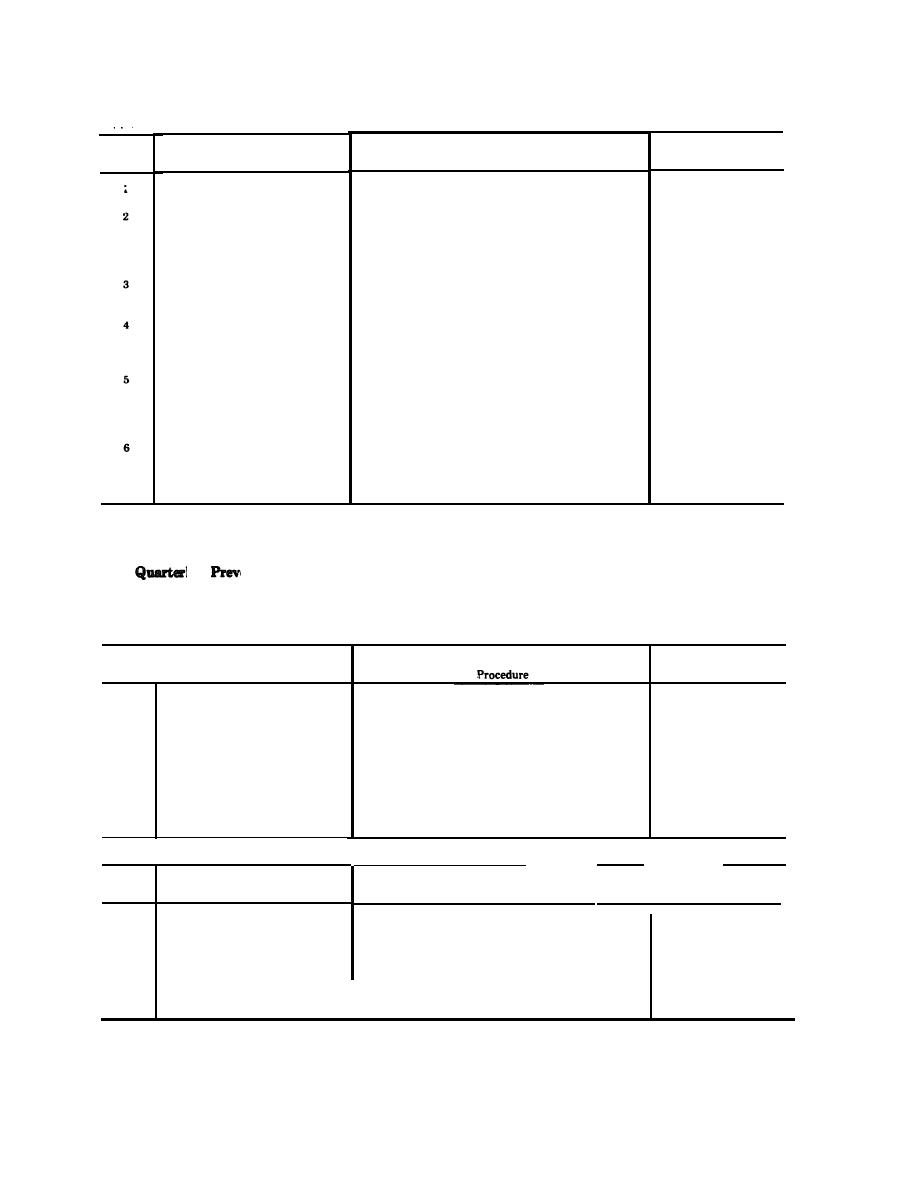

Quarterly preventive maintenance checks and Service Charts |

|

||

| ||||||||||

|

|

TM11-5895-932-14&P

a Patch and Test Facility (Monthly).

Sequence

References

Procedure

Item to be inspected

No

Inspect the station grounding system

Grounding System

Check all hinges. latches, and metal-to-metal

Movable parts

moving parts, as necessary

Para 4-8 and 4-9

a Clean and paint bare metal parts

b Clean all air filters

None

Repair insulation cuts and abrasions with electrical

Cables, wires, and cords

insulation tape

Report any indication of defective switches, switch-

None

Electrical system

plates, outlets, and receptacles to Post Mainte-

nance

None

Check to see that equipment mounting racks.

Equipment mountings

frames, shelves, braces, and clamps are not bent.

broken, or out of shape to endanger equipment or

personnel

None

Check fuses at equipment Replace defective fuses

Fuses

Verify that all operating fuses are of the correct

value Check spare fuses for proper value and quan-

tity

(Monthly). Perform periodic

required on the PTF. Periodic daily, weekly and

b. Equipment

monthly services constitute a part of the quarterly

checks and services on each equipment in the

preventive maintenance checks and services and

facility (app A).

must be performed concurrently. All deficiencies

entive Maintenance Checks

ly

will be recorded and corrected.

and Service Charts

Quarterly preventive maintenance checks are

a. Patch and Test Facility (Quarterly).

Sequence

References

No

Item to be inspected

I

1

Publications

Check to see that all publications are complete.

None

serviceable. and current

None

2

Mounting

Verify that all bolts, nuts, and washers are cor-

rectly positioned and properly tightened Check for

cracked, bent, or broken brackets

3

Spare parts

Check all spare parts for general condition and

None

method of storage There should be no evidence of

overstock. and all shortages must be on requisition

b. Equipment (Quarterly).

Sequence

No

Item to be inspected

Procedure

References

1

Appendix B

See that the equipment

complete

IS

2

Preservation

Check all surfaces for evidence of fungus Remove

Para 4-8 and para 4-9

rust and corrosion and spot-paw bare spots

Verify that plugs. sockets, and lacks are clean, ml-

None

tact. and not loose fitting

3

Connections

I

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |