|

|||

|

|

|||

|

Page Title:

Section IV. CLEANING, INSPECTION, AND REPAIR |

|

||

| ||||||||||

|

|

TM 11 5840-270-24-1

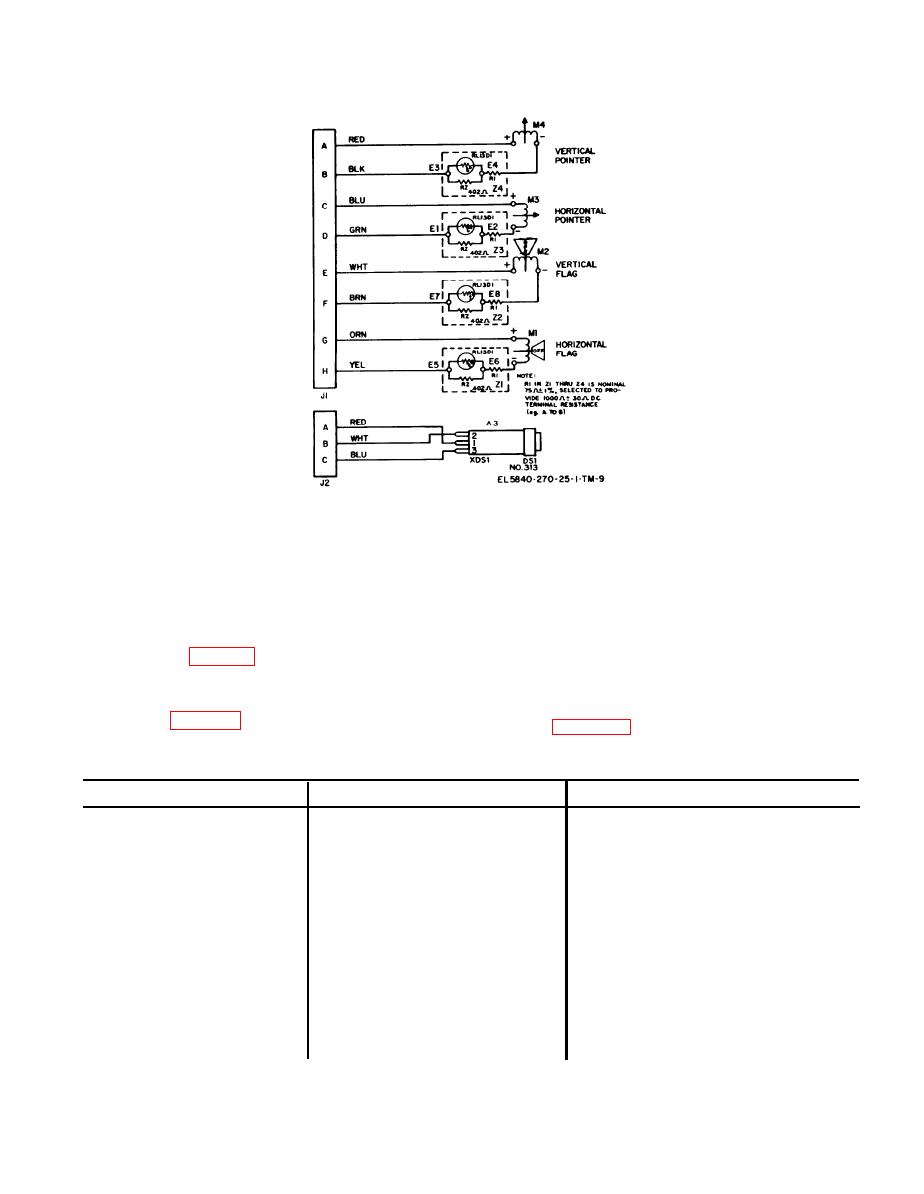

Figure 4-5. Schematic diagram.

Section IV. CLEANING, INSPECTION, AND REPAIR

4-14. Cleaning

4-16. Repair

After disassembly, clean the parts of the indicator

Except for minor dents and scratches, no repair is

as specified in table 4-1.

possible. Replace all parts that are defective or

damaged. If a meter mechanism or compensating

4-15. Inspection

network is replaced, R1 on the network may

Inspect all parts of the disassembled indicator as

require changing to obtain 1000-ohm terminal

indicated in table 4-1.

resistance (para 4-20).

Table 4-1. Cleaning and Inspection of Indicator ID-48A/ARN

Inspection

Part

Cleaning

Mechanism Ml, M2, M3, M4.

Inspect for loose or broken wires and

Movements . . . . . . . . . . . . . . . . . .

Remove any fuzz of lint using a soft

loosely mounted pivot bases.

bristle brush or low pressure air

source. Do not use cleaning fluid.

Inspect for bent or dirty pointer, loose

Pointers . . . . . . . . . . . . . . . . . . . . . .

L u m i n e s c e n t painted surface may

balance weights or chipped surface.

be cleaned with benzine.

Pointer should be perpendicular to the

moving coil and parallel to the dial

when mounted.

None.

Clean with acetone. . . . . . . . . . . . .

Pointer Stops . . . . . . . . . . . . . .

I n s p e c t for poor solder joints, loose

C l e a n connections and terminals

Wiring a n d S o l d e r e d C o n -

before resoldering.

connections and mounting, broken or

nections.

shorted wires.

Clean dirty markings with a cloth

Inspect for chipped or dirty luminous

Dial MP11 and Mask MP4.

moistened with benzine.

marking.

Wipe clean with soft cloth.

I n s p e c t for scratched or broken glass,

Window MP5 . . . . . . . . . . . . . . . .

loose mounting.

4-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |