|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 11-3895-209-14

4-3. CHECKING UNPACKED EQUIPMENT

Inspect the equipment for damage incurred during shipment. If the equipment has been damaged,

report the damage on SF 364.

See that the equipment is complete as listed on the packing slip. If the packing slip is not available,

check the equipment against the basic issue items list (appx B). Report all discrepancies in

accordance with DA Pam 738-750.

If the equipment has been used or reconditioned, see whether it has been changed by modification

work order (MWO). If the equipment has been modified, the MWO number will appear on the front

panel near the nomenclature plate. Check to see whether the MWO number (if any) and approoriate

notations concerning the modification have been entered in the equipment rnanual.

NOTE

Current MWO'S applicable to the equipment are listed in DA Pam 310-1.

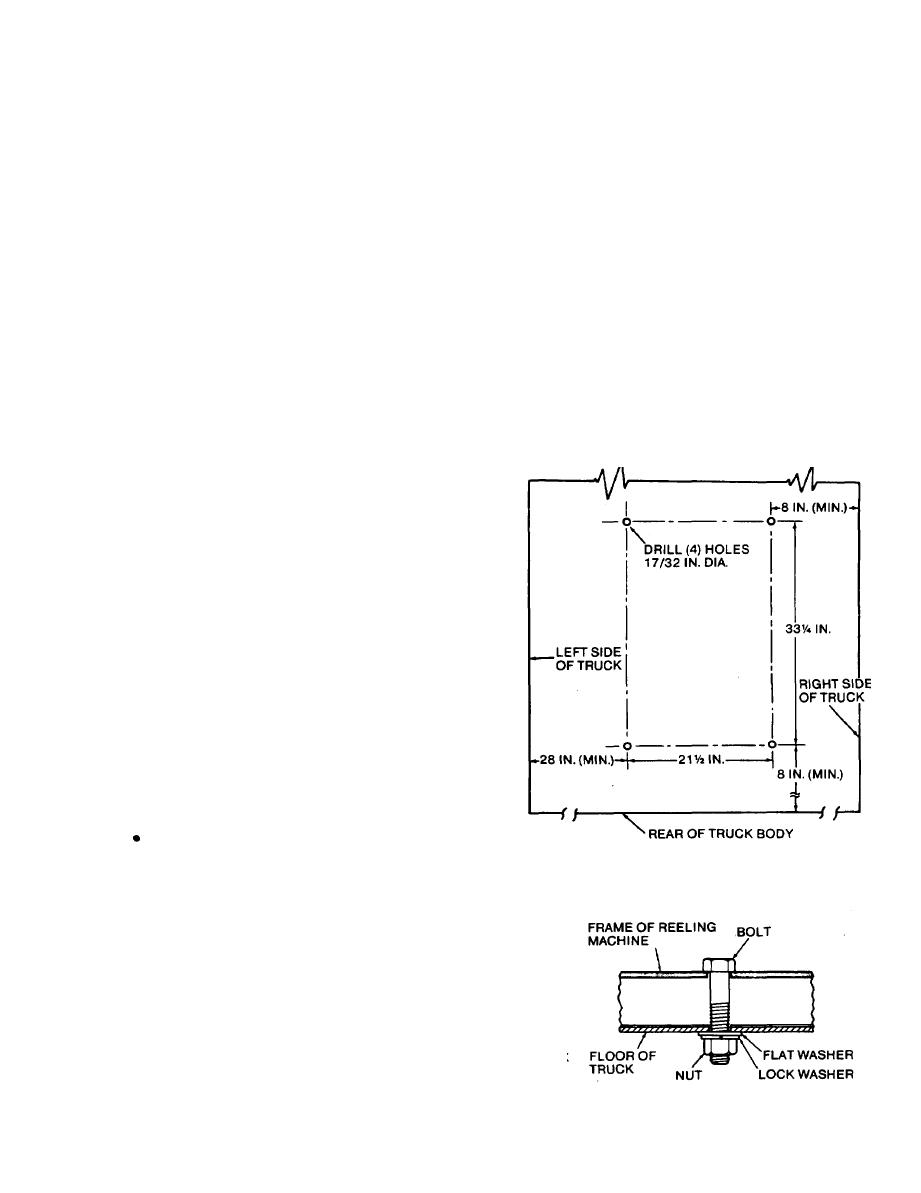

4-4. INSTALLATION ON VEHICLE

Minimum Clearances Required

TYPE OF VEHICLE

The RL-207(*)/G maybe mounted in the body

of the 1 ton, 4X4 Cargo Truck M880/M-1008

or 2 ton, 6X6 Cargo Truck M35A2. A floor-

space of at least 6 feet by 5 feet is required for

operation.

MATERIALS AND TOOLS REQUIRED

The following materials and tools are required

to install the RL-207(*)/G in a vehicle:

A Electric drill, 3/4-inch

B Twist drill, 3/4-inch

C Hexagonal head bolt, 1/2-20 x 2 1/2

inches (four required)

D Hexagonal nut, 1 -2/20 (four required)

E Flat washer, 1/2-inch (four required)

F Split lock washer (four required)

INSTALLATION

A Locate and mark the position of each of the four

mounting holes in the bed of the truck body.

CAUTION

Check to be sure the underside of the

truck body is clear before drilling any of

the holes.

B Drill the four 17/34-inch holes through the bed of the

truck body.

C Set the RL-207(*)/G over the holes. Use a forklift truck

or hoist to lift the RL-207(*)/G.

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |