|

|||

|

|

|||

|

Page Title:

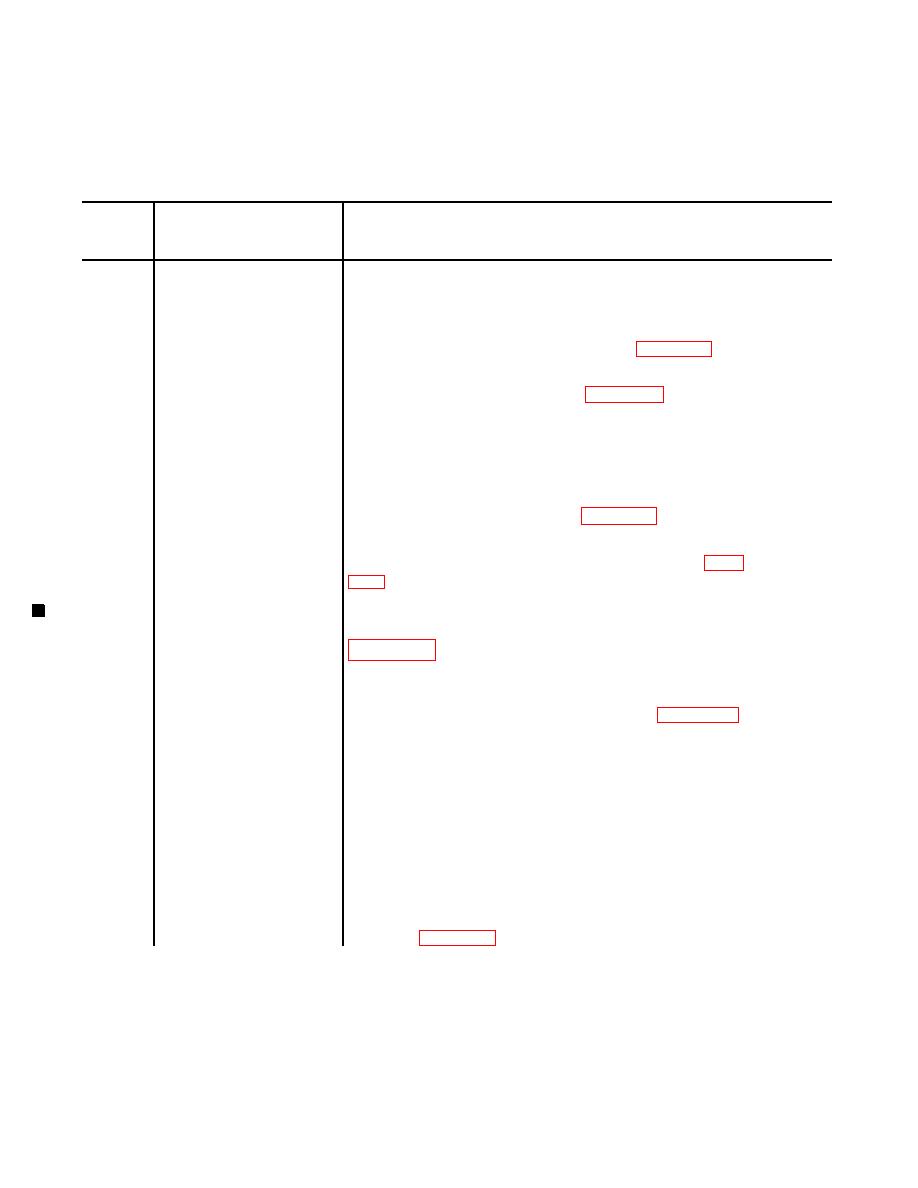

Table 4-1. Organizational Preventive Maintenance Checks and Services Quarterly Schedule |

|

||

| ||||||||||

|

|

TM 10-7360-204-13&P

Table 4-1.

Organizational Preventive Maintenance

Checks and Services Quarterly Schedule

Item

Item

No.

to be

Procedures

Inspected

Cabinet Assembly

1

Lid

Inspect for improper closing, cracked or broken hinges, and

defective brace or handle. Replace a defective lid. Inspect the

lid hinge retainer and replace if necessary (para 4-8.1).

2

Lifting Handle

Check for breaks, binding, and loose or missing rivets.

Replace a defective lifting handle (para 4-8.2).

3

Accessory Items

Inspect all accessory items for serviceability; repair or replace any

unserviceable items.

Burner Assembly

4

Top and Bottom Shields

Inspect for cracks, bends, and missing, or distorted springs.

Repair or replace a damaged part (para 4-9.1).

5

Spare

Inspect for dents and broken, loose or missing fittings.

Check for leaks. Replace a defective spare generator (para

6

Air Valve Assembly

Inspect for leaks and improper operation while pressurizing

the unit. If valve leaks, shut unit down and replace air valve assembly

7

Fuel Tank

Inspect for leaks from drain plug. If defective, replace.

Check fuel tank for cracks, broken welds, damaged threads

and other leaks. Replace a damaged fuel tank (para 4-9.6).

Check fuel filler cap for cracks, damaged threads, defective

gasket, and leaks. Replace a defective cap or gasket.

8

Preheater

Inspect preheater valve for leaks and improper operation. If

valve leaks, shut down unit. Check for leaks between valve

stem and packing nut. Tighten packing nut or repack valve

as required. Replace a defective valve. Inspect the preheater

head and shield for bends and breaks. Check the head for

loose mounting. Inspect the orifice cleaning control for binding or

improper operation. Inspect the preheater head

bushing for damaged threads. Replace or repair the

preheater (para 4-9.4).

4-2

Change 11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |