|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TB 9-2300-247-40

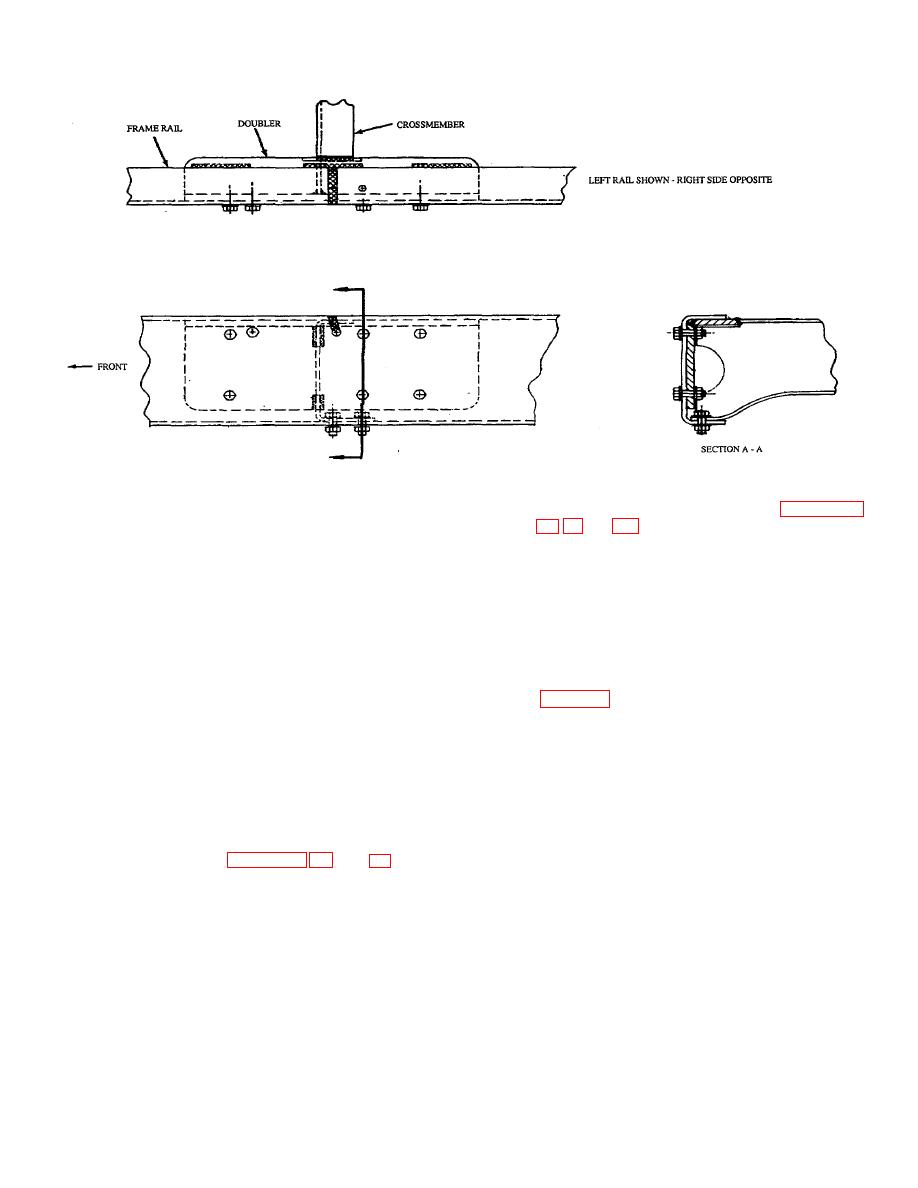

Figure 45. Repair at Crossmember (Upper Flange)

b. Fabricate doubler plate as shown in Figures 42,

NOTE

The

exact

doubler

location

c.

Bevel the doubler at the gap to a 450 angle.

determines the length of the cutout in

the trapezoid plate.

d. Securely bolt the doubler to the plate using new

No. 8 UNF bolts, washers, and locknuts. Torque

60.

Repair Procedure

bolts in accordance with appendix E of the

appropriate vehicle TM.

WARNING

e. Secure doubler to the rail and repair as shown in

Use Only effective chip guarding

equipment, protective equipment and

protective clothing (goggles, shields,

f.

Thoroughly clean repaired

surfaces

and

gloves aprons, etc when doing any

surrounding area of repair.

drilling, grinding, or welding. Failure

to follow this warning could result in

g. Prime and paint repair area and surrounding

injury to personnel.

surfaces as specified in TM-43-0139.

a. Using an oxyacetylene torch, provide cutouts in

61.

Defect. Cracks at jounce bracket requiring

the trapezoid plate with a maximum 5/32-inch

cutouts of portions of the trapezoid plate to accept the

gap as shown in Figures 47, 48, and 49 which

doubler flange and the addition of spacer.

specify the fabrication of doubler plates and

repairs to defective trapezoidal areas.

40

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |