|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2300-247-40

holes in frame and doubler to assure a firm and

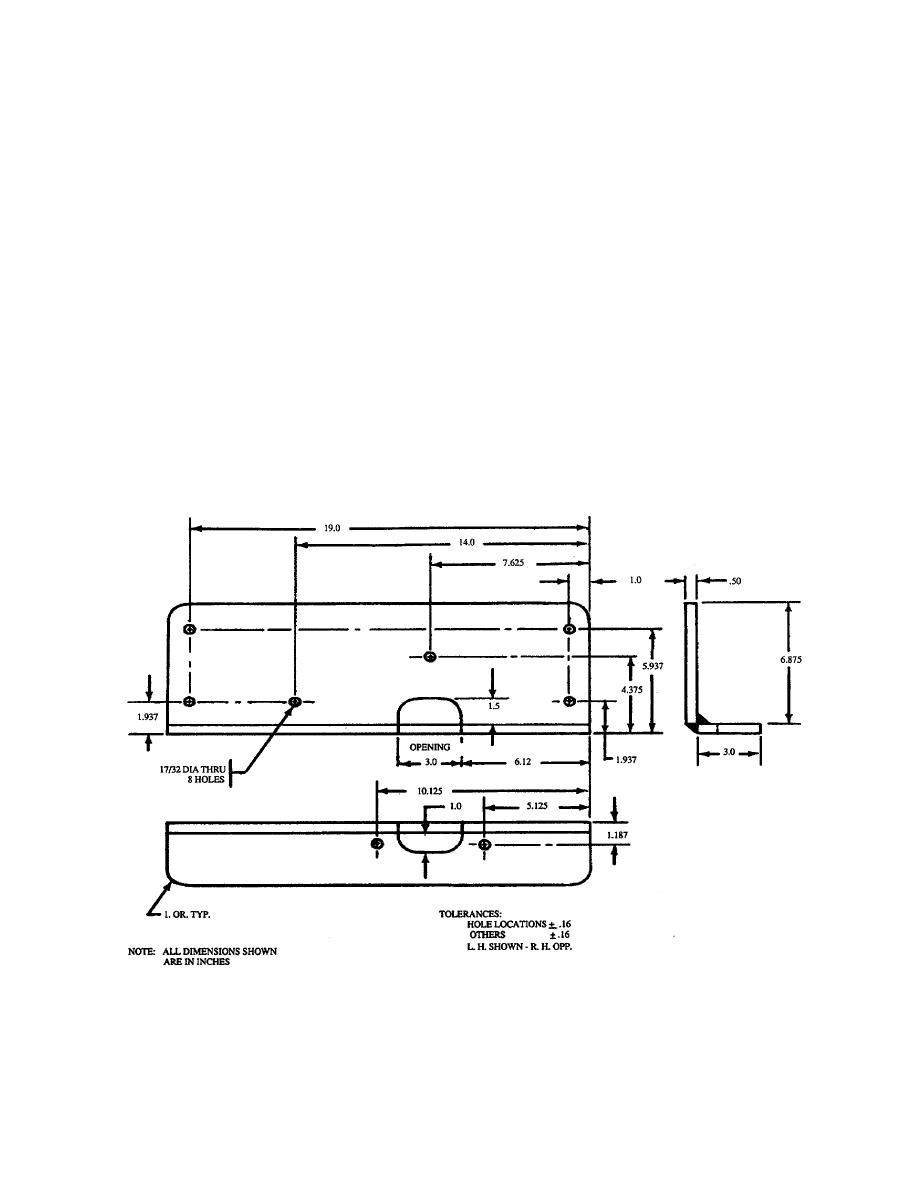

62.

Doubler Plate Fabrication.

secure attachment of the repair and to meet the

requirements for minimum bolt configuration on

a. Use 1/2-inch Society of Automotive Engineers

each side of the crack and to assure a tightly

(SAE) steel plate, NSN 9515-02-222-5059.

mated surface and proper stress distribution.

Such additional holes may be drilled after

WARNING

doubler has been attached to the rail.

Use Only effective chip guarding

d. Where required, grind inside fillet welds to

equipment, protective equipment and

assure positive contact between washer and

protective clothing (goggles, shields,

doubler mating surfaces.

gloves aprons, etc) when doing any

drilling, grinding, or welding. Failure

e. When mating doubler to frame, ream doubler

to follow this warning could result in

and frame rail holes as required for proper hole

injury to personnel.

alinement and tight fit of attaching hardware.

b. Using an oxyacetylene torch, cut and trim the

f.

Where it is necessary to remove elongation in

fabricated doubler to the desired form. Grind all

holes, holes may be enlarged to accept a larger

edges to a smooth finish. The outside edges

bolt.

shall be no closer to a bolt hole than 1/2-inch.

c.

Drill all holes in doubler to template and to

location of repair area. Where required, provide

Figure 49. Doubler at Jounce Bracket

43

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |