|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TB 9-1430-1533-40-1

Section II. COOLANT CLEANING

5. Preparation of Cleaning Station.

6. Preparation for Cleaning the HIPIR Cooling

a. Fill reservoir No. 1 to within two inches of the

System.

rim with hot (160F) tapwater. Pour in two pounds of

Versene-Acid and stir with a wooden paddle until powder

CAUTION

dissolves. Place cover on reservoir.

b. Fill reservoir No. 2 to within two inches of the

In performing the following purging

rim with hot (160F) tapwater. Pour in three ounces of

procedure, the pump may be

concentrated liquid soap (alkali-free) and stir for a few

operated

without

the

required

seconds. Place cover on reservoir.

lubrication provided by the coolant;

c. Fill reservoir No. 3 to within two inches of the

as a result, the life of the pump is

rim with hot (160F) tapwater. Pour in two pounds of

affected. Therefore, it is important

pyrosulphate and stir with a wooden paddle until powder

that operation of the pump not

dissolves. Place cover on reservoir.

exceed the time noted in the

d. Fill reservoir No. 4 to within two inches of the

procedure:

rim with distillated or demineralized water. Place cover

on reservoir.

NOTE

e. Fill reservoir No. 5 to within two inches of the

rim with Ethylene Glycol. Place cover on reservoir.

To achieve maximum results, it is

f. Set the main power switch and the control

necessary, when performing this

current switch to ON.

cleaning procedure on the HIPIR for

g. Set the heater control switch to position I & II (fig.

the first time, to clean the coolant

fluid reservoir (1, figure 5) and the

h. Adjust thermostat to 160F.

heat

exchange

(2,

figure

5)

separately.

MS011044

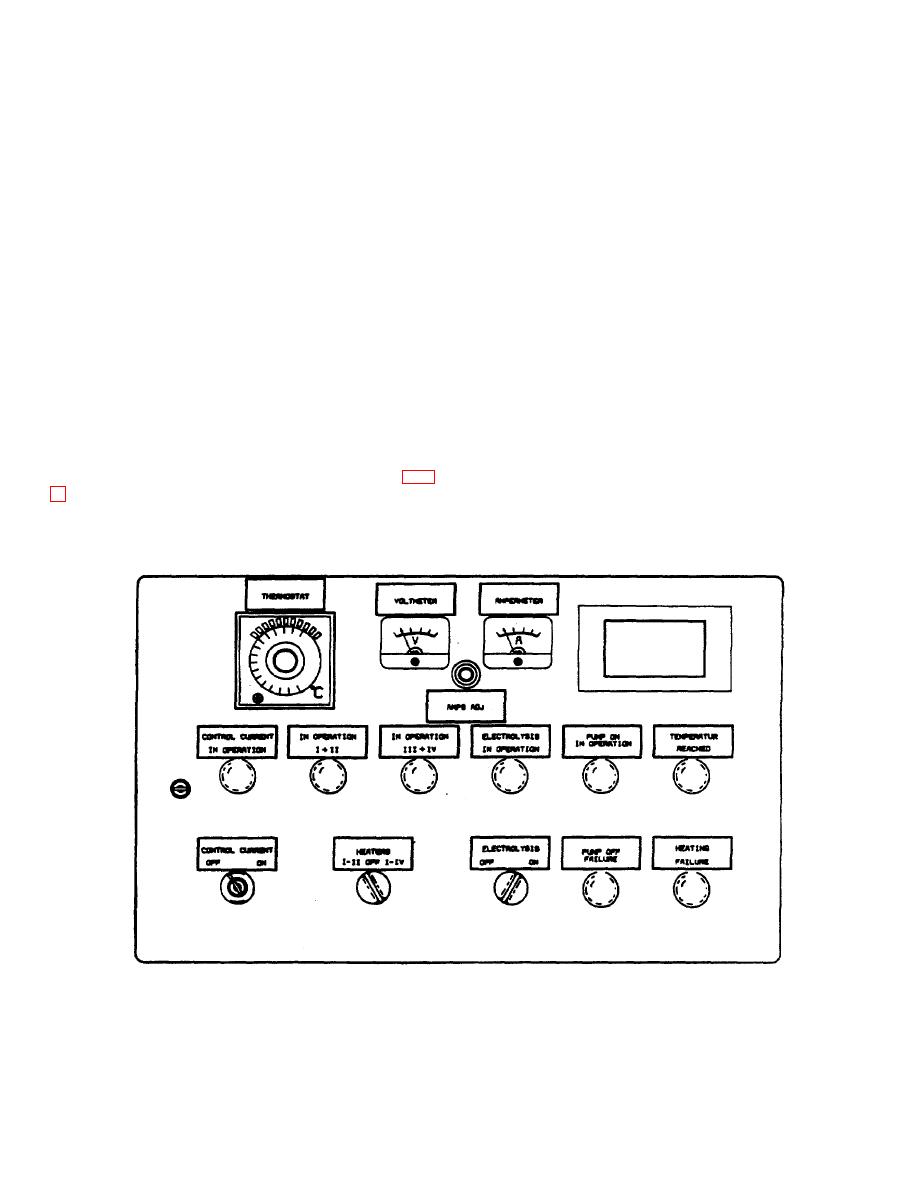

Figure 2. Cleaning unit controls.

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |