|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

MISCELLANEOUS MAINTENANCE

VEE BELTS

CHECKING BELTS

ADJUSTING BELT TENSION

1.

Check belt wear.

2.

Check tension of each belt

Alternator Drive (Fig. A)

1. Loosen the bolts on the alternator.

If one belt in a set requires replacement, always install

2. Move the alternator until the belt is properly

a new matched set of belts-never replace just the worn

adjusted. Tighten the adjustment bolt.

belt. If only the worn belt is replaced, the new belt will

3. Check the adjustment.

be carrying all of the load-as it will not be stretched as

4. Tighten the bolt.

much as the older belts-and all of the belts will-fail in

rapid succession.

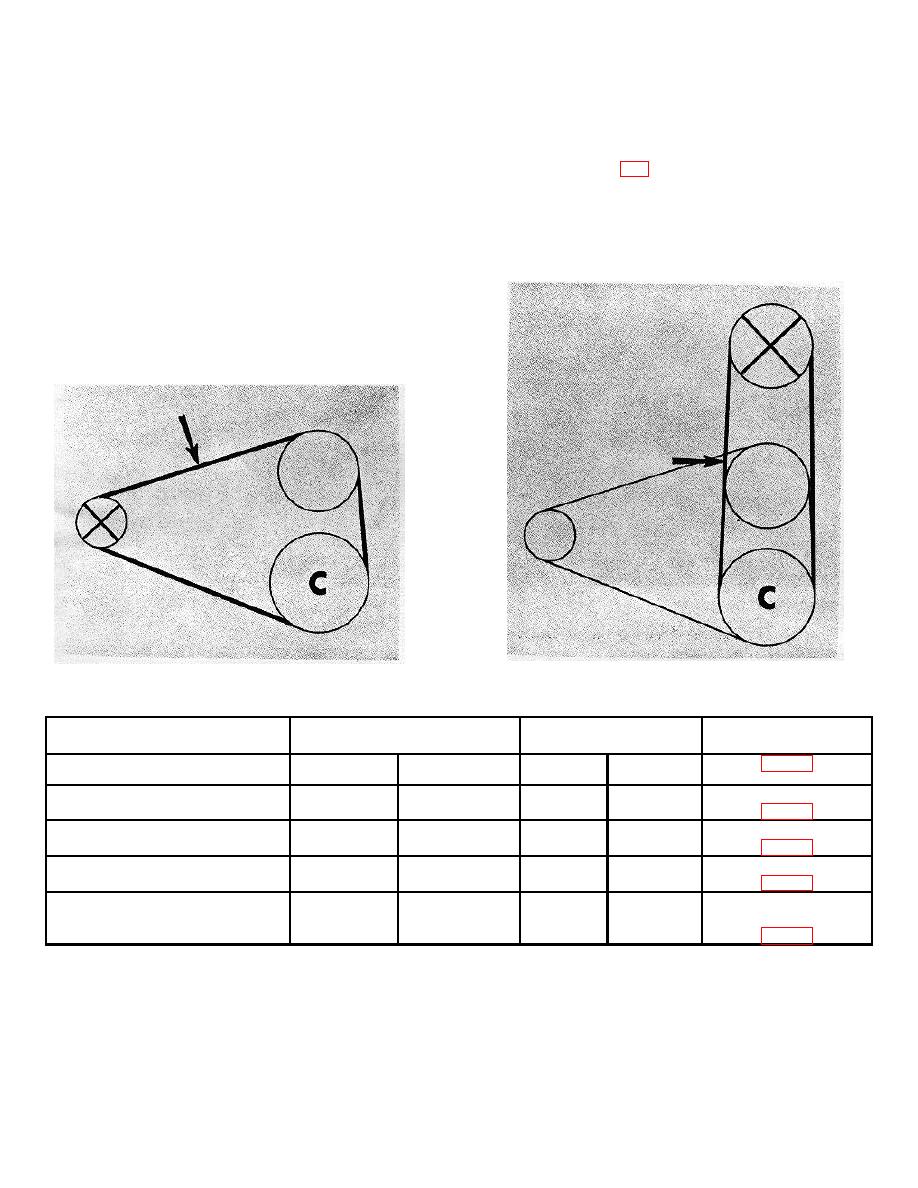

In the following illustrations the pulley marked X is the

adjusting pulley. The pulley marked C is the crankshaft.

Force is applied at the arrow. See the chart for the

force and belt deflection.

FIG. B HIGH MOUNT FAN DRIVE

FIG. A ALTERNATOR DRIVE AND WATER DRIVE

ATTACHMENT

FORCE

BELT

FOR SCHEMATIC

DEFLECTION

SEE:

Alternator Drive

5 lbs.

227 gms.

0.25 in.

6.5 mm

Water Pump-Fan Drive

5 lbs.

227 gms.

0.25 in.

6.5 mm

High Mount Fan Drive

5 lbs.

227 gms.

0.25 in.

6.5 mm

Air Compressor Drive

6 lbs

272 gms.

0.25 in.

6.5 mm

Air Compressor Drive

w/high mount fan

4 lbs.

182 gms.

0.12 in.

3.0 mm

22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |