|

|||

|

|

|||

|

Page Title:

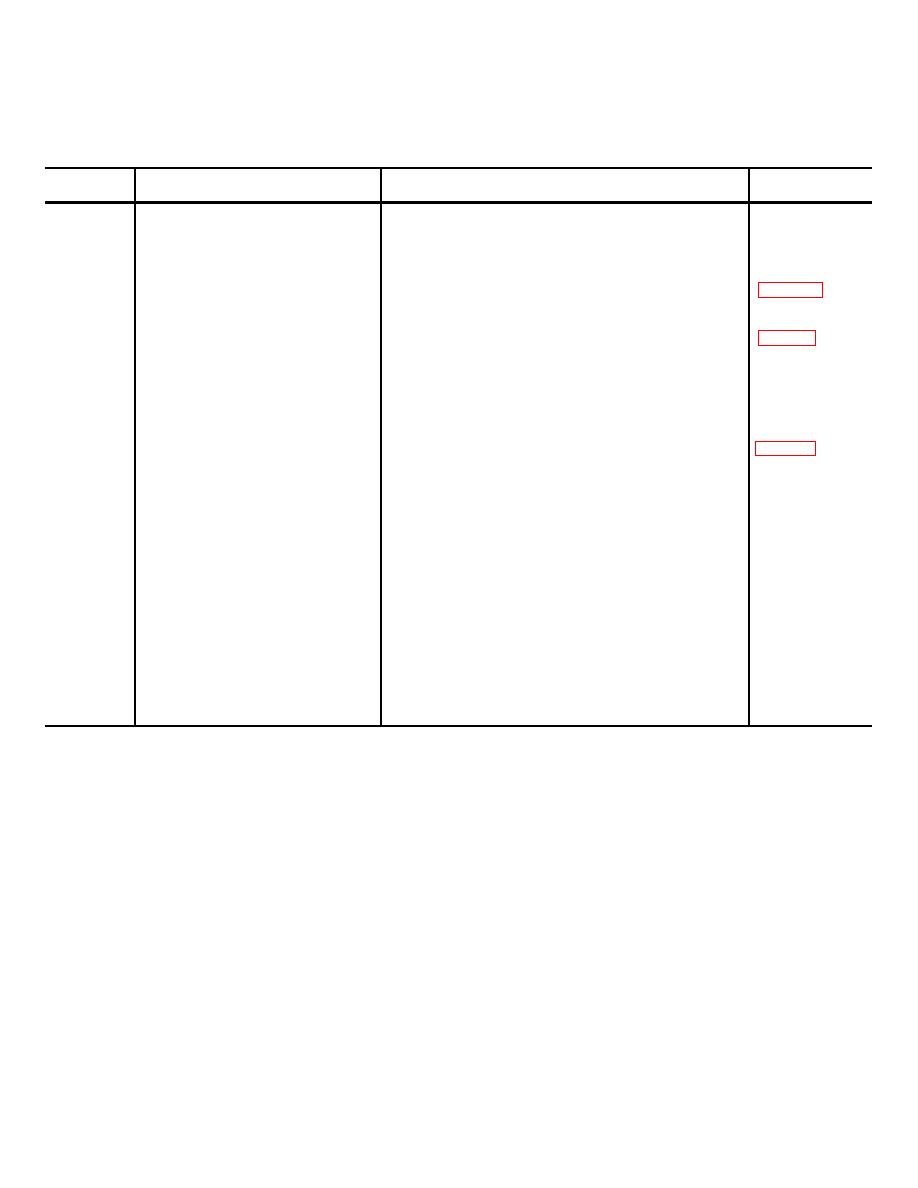

Table 2-1. Preventive Maintenance Checks and Services |

|

||

| ||||||||||

|

|

TM 5-4310-340-24

Table 2-1. Preventive Maintenance Checks and Services

Organizational Maintenance

Quarterly Schedule

Sequence

Item to be

Paragraph

number

inspected

Procedure

Reference

BEFORE OPERATING COMPRESSOR

1

Lubricating oil.

Check level. Add or change oil as required.

LO 9-2350-232-12

2

Oil level dipstick.

Check dipstick and preformed packing for damage.

Replace damaged parts.

3

Screws. nuts. brackets, and clamps

Check for looseness. Tighten as required.

4

Coolers

Check for bent fins and loose connections. Straighten

(para 1-15)

fins and tighten connections as required.

COMPRESSOR OPERATING

5

Oil tubes. fittings. and gaskets.

Check for leaks. If leaks are found, stop compressor and

tighten defective tube or fitting as required. Operate

compressor and recheck leak. If leak continues and

cannot be stopped, stop compressor and notify direct

support maintenance.

6

Compressor assembly

Listen for any unusual noises. If unusual noises are

heard. locate and correct cause. If cause cannot be

corrected at organizational level, stop compressor and

notify direct support maintenance.

7

Compressor assembly

Check for vibration, overheating, or smoking. If

overheating, vibrations, or smoking exist, stop

compressor and notify direct support maintenance.

8

Compressor assembly

Check for proper operation. If air supply is insufficient,

and the compressor is at fault, stop compressor and

notify direct support maintenance.

2-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |