|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

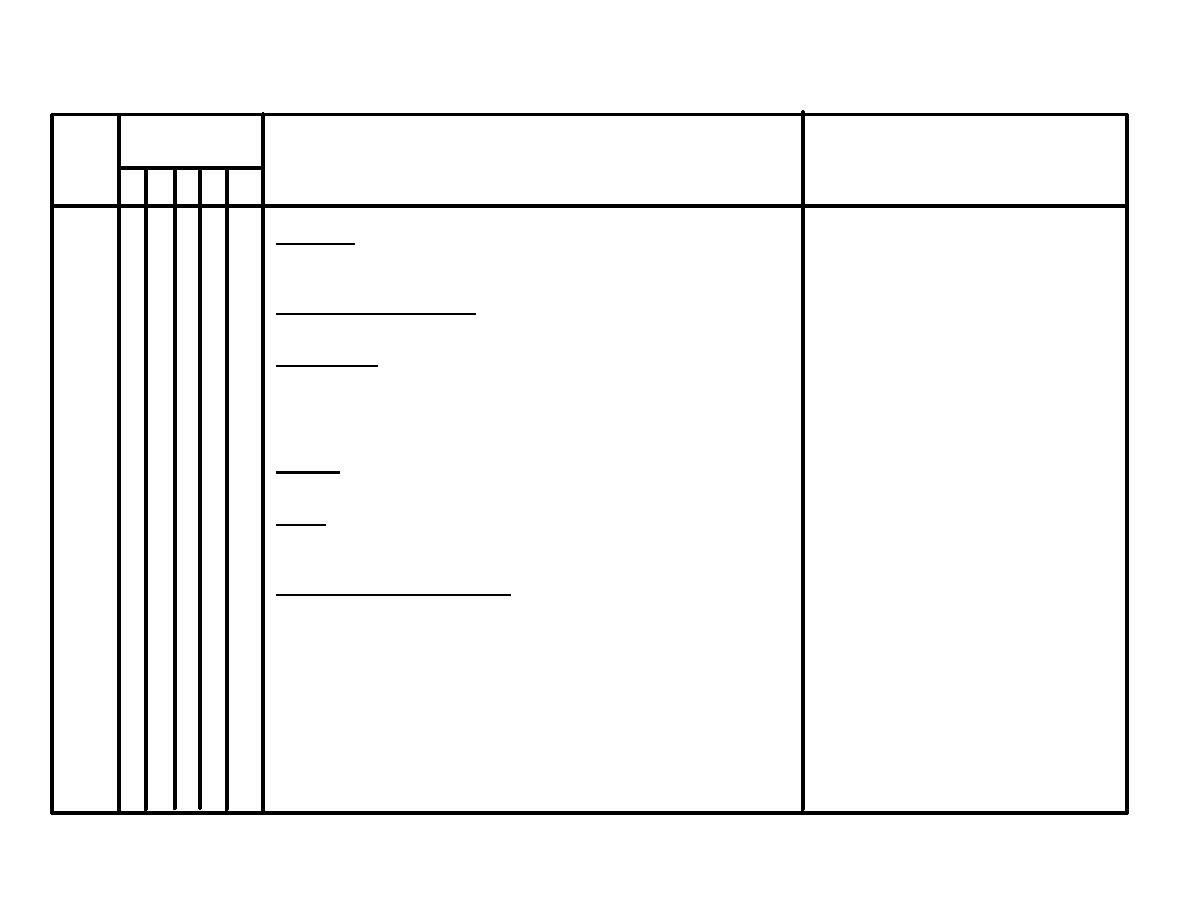

OPERATOR/CREW PREVENTIVE MAINTENANCE CHECKS AND SERVICES

B Before

D During

A After

W Weekly

M Monthly

ITEMS TO BE INSPECTED

INTERVAL

PROCEDURE: Check for and have repaired, filled or

Equipment is not ready/

ITEM

adjusted as needed.

AVAILABLE IF:

NO.

B

D

AW

M

5

RADIATOR

Check coolant level. Add coolant as required (Level should be

1/2 inch from bottom of filler neck).

6

BRAKE MASTER CYLINDER

Check brake cylinder fluid level. Add as required.

7

AIR CLEANER

a. Check air cleaner indicator. If red, clean or replace air

filter element.

b. Inspect air cleaner element.

Element missing.

8

V BELTS

Check for frayed, cracked, or broken belts

Broken belt.

9

AXLES

Check differential and planetary oil level (allow 5 min for

oil to settle).

10

CONTROLS AND INSTRUMENTS

a. Engine water temperature gauge (normal operating tempera-

If any are not within normal

ture 165-195 ).

F

operating range.

b. Engine oil pressure gauge (Idle 10-25 psi, rated speed

2800 RPM) 45-75 psi).

c.

Converter "out" oil pressure gauge (25-70 psi).

d. Transmission oil temperature gauge (180-250F).

40

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |