|

|||

|

|

|||

|

Page Title:

CONNECTION OF GOVERNOR TO FUEL INJECTION PUMP HOUSING (CONT) |

|

||

| ||||||||||

|

|

3208 INDUSTRIAL AND MARINE ENGINES

DISASSEMBLY AND ASSEMBLY

FUEL INJECTION PUMP HOUSING AND GOVERNOR

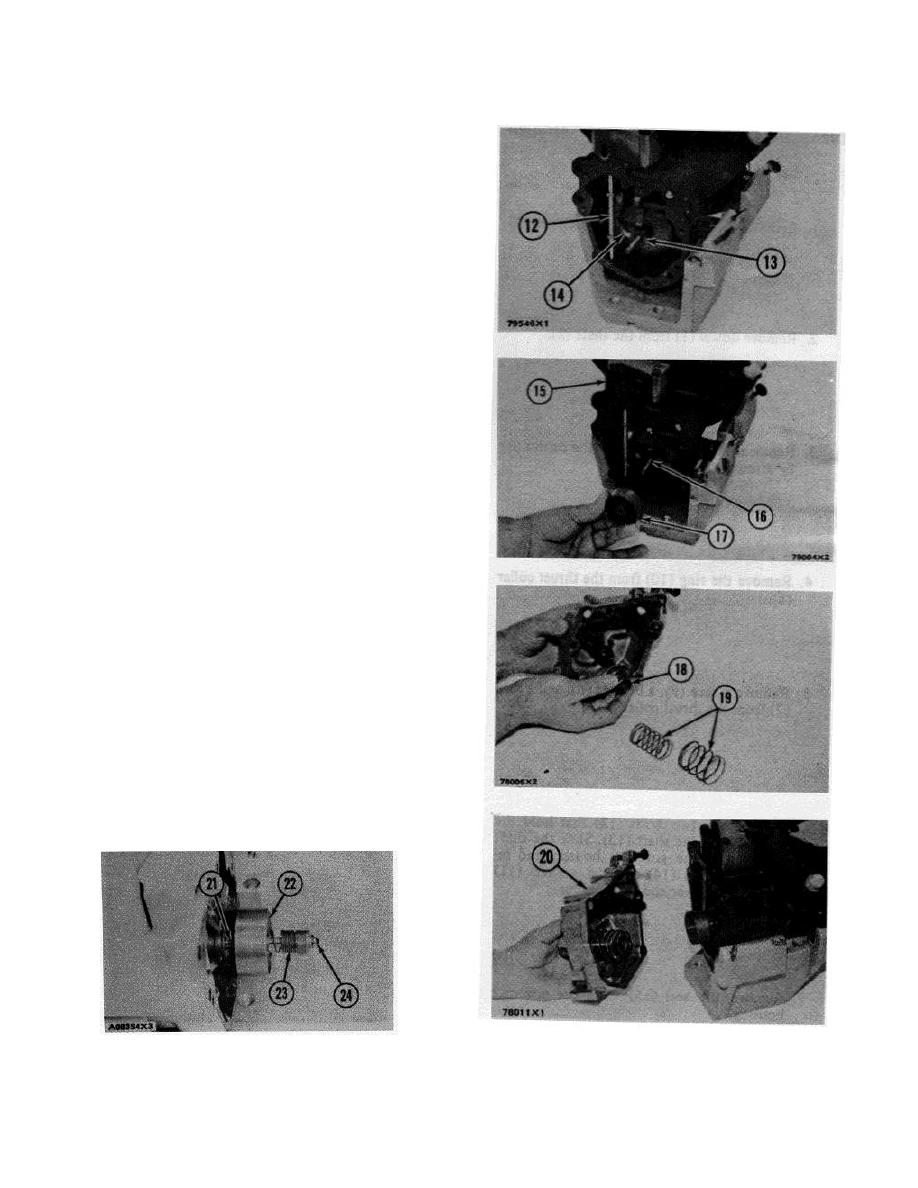

14. Put the thrust collar (13) in position be-

tween the flyweights. Lift the flyweights up

with a piece of wire and push the thrust

collar (13) forward.

15. Put the lever (14) in position in the housing

and in the groove of the thrust collar (13).

Put a new O-ring seal on the shaft and in-

stall the shaft (12) down through the hous-

ing and into the holes in lever (14).

16.

Install the cover (15) on the pump housing.

17.

Install the spring (16) on the shaft.

18.

Install the seat (17) on the shaft.

19.

Install the seat (18) and two springs (19) in

the governor housing.

CAUTION: Both springs must make a full seat on

seat (18) before installing in governor housing. If

springs do not make a full seat, high idle speed

will not be correct. Low idle governor surge can

be caused by springs not making a full seat. It

can also prevent getting a low idle setting with

stability.

20. Install the governor housing (20) on the

pump housing.

21. For fuel systems equipped with a dashpot

governor, install spring (21) on shaft (24).

Install seat and piston assembly (22) on

shaft (24). Turn spring (23) on the piston

and seat until it just contacts the shoulders

on the piston and seat.

end by:

a) make an adjustment of the fuel sys-

tem setting (See FUEL SYSTEM in

TESTING AND ADJUSTING)

b) install fuel injection pump housing

and governor

31

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |