|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

FUEL SYSTEM

TESTING AND ADJUSTMENT

reading of the pressure on the gauge to be almost

constant when the valve in the fuel injection nozzle

opens. The pressure needed to open the valve must

be the same as shown in the chart. If the opening

pressure is less than 2200 psi (154.7 kg/cm2), do not

use the fuel injection nozzle again.

NOTE: The valve in the fuel injection nozzle can be good

and still not make a noise (chatter), or not have a very fine

vapor (spray) from the orifices in the tip of the fuel injection

nozzle during Step 2.

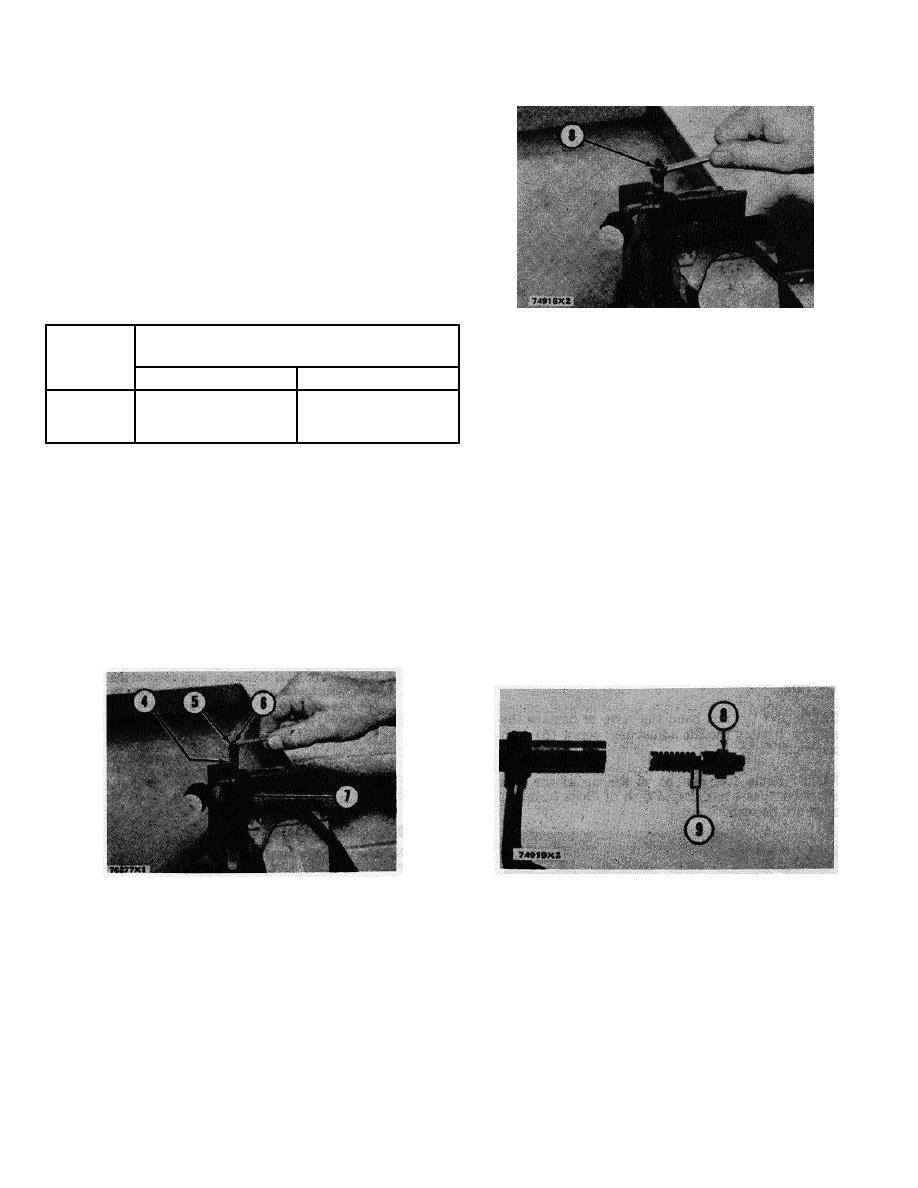

LOOSENING PRESSURE SCREW

OPENING PRESSURE

8. Pressure screw.

VALVE NO.

Used

New

c. Tilt the fuel injection nozzle down, a small amount,

9L7883

2400 to 2900 psi

2750 to 2900 psi

from the vertical position and remove pressure screw

2

2)

(168.7 to 203.9 kg/cm )

(193.3 to 203.9 kg/crn

(8) and shims (9).

NOTE: If shims (9) do not come out of the fuel injection

NOTE: The correct setting of the opening pressure for used

nozzle, turn the fuel injection nozzle over and let the

nozzles that have been cleaned is 2700 to 2900 psi (189.8

shims, spring, and spring seat fall into your hand. The

to 203.9 kg/cm2 ).

valve can come out of the body by its own weight and must

be held carefully by the stem.

3. To make an adjustment to the opening pressure, use

the following procedure:

d. To make an increase in the opening pressure add a

4N5730 Shim. The 4N5730 Shim is .005 in. (0.13

a. Remove the fuel injection nozzle (4) from the

mm) thick and will increase the opening pressure

8S2267 Nozzle Tester and put it in the 8S2250

2

approximately 250 psi (17.8 kg/cm ) maximum of

Nozzle Holding Tool (7). Loosen Locknut (5). Turn

two shims can be added to make an increase in the

lift adjustment screw (6) counterclockwise two or

opening pressure.

three turns.

PRESSURE SCREW AND SHIMS

LOOSENING LOCKNUT

8. Pressure screw. 9. Shims.

4. Fuel injection nozzle. 5. Locknut. 6. Lift

adjustment screw. 7. 8S2250 Nozzle Holding

Tool.

CAUTION: If the lift adjustment screw (6) is not loosened,

e. Assemble the fuel injection nozzle being sure the

the valve can be bent or the seat for the valve can be

thicker shim is against the pressure screw as shown.

damaged when the fuel injection nozzle is assembled in

Put the fuel injection nozzle in the 8S2250 Nozzle

Step e.

Holding Tool. Put the nozzle holding tool in a vise

and tighten the pressure screw (8) to 75 to 80 lb. in.

b. Loosen the pressure screw (8). Remove the fuel

(86.5 to 92.2 cm. kg).

injection nozzle from the 8S2250 Nozzle Holding

Tool (7).

51

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |