|

|||

|

|

|||

|

Page Title:

CHAPTER 3 MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

TM 3-4240-201-13

CHAPTER 3

MAINTENANCE INSTRUCTIONS

Section I.

PREVENTIVE MAINTENANCE CHECKS AND SERVICES

3-1.

General

3-2.

Preventive

Maintenance

Checks

and

Services

This section provides in table 3-1 the operator with a list

of services which must be performed at the intervals

prescribed. Intervals of maintenance are based on

provides a list of services that the operator must perform

normal operation and will be reduced or extended

either before or after operation.

Defects that are

depending on operating conditions. The filter unit will

discovered during preventive maintenance servicing

normally be used on very short notice. This equipment

must be corrected immediately. The number also

must be kept in a constant state of readiness.

indicates the sequence in which the service must be

performed.

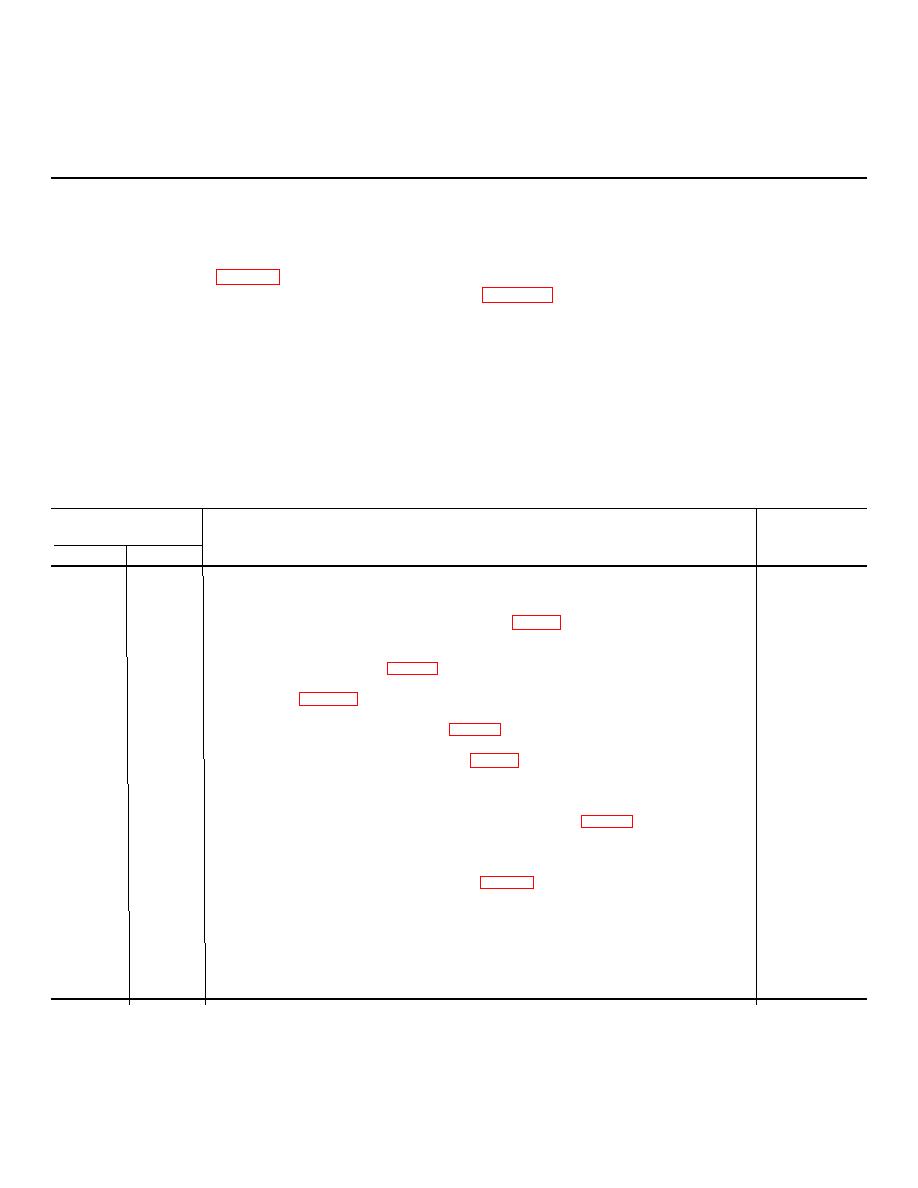

Table 3-1. Preventive Maintenance Checks and Services

B-Before operation

A-After operation

Time required: 1.1 hours

Time required: 1 hour

Interval and

Item to be inspected procedure

Work

Sequence No.

Time

B

A

(M/H)

1

9

Publication. See that a copy of TM 3-4240-201-13 is available and in serviceable con-

0.1

dition.

2

10

Overall Visual Inspection. See that the filter unit (fig. 1-1) is clean and all parts are

0.2

free of rust, pitting, corrosion, and dry rot. See that none of the components are

missing or damaged.

3

11

Air Purifier. Check housing (fig. 1-4) for dents and loose connections. Notify organi-

0.1

zational maintenance to replace gas filter and particulate filter when they become

contaminated (table 2-1). See that airflow control caps are in place and in good

condition.

4

12

Transformer. Check transformer case (fig. 1-5) for damaged, loose, or missing cables,

0.1

damaged connectors, loose or missing screws, and broken toggle switch.

5

13

Battery. Check electrolyte level in battery (fig. 1-1) cells visually. Maintain liquid

0.1

level in battery cells by adding distilled water as necessary. Clean the terminals and

remove corrosion. See that protective cable nipples cover both clips of the 24 volt dc

power cable.

6

14

Hoses. See that hoses are routed according to the diagram (fig. 2-1). See that hoses

0.2

are not stretched or sharply bent. See that loop clamps are used to support hoses along

their lengths. Check ratchet clamps, inlet adapter, pulomatic plug, and Y-fittings for

damage.

7

15

Headpiece and Carrier. Check headpieces (fig. 1-2) for cleanliness, holes, and loose

0.2

or cracked plastic material. See that inlet adapter mount, strap, and outlet valve are

not damaged. Check for missing carriers.

8

16

Operational Check. Move toggle switch to ON position to see that it operates. Remove

0.1

115 vac power cable from ac power source to see that it automatically transfers to

dc power source. If it is satisfactory, place toggle switch to OFF position. Plug the

115 vac power cable in to the power source.

3-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |