|

|||

|

|

|||

|

Page Title:

FOG OIL EXHAUST HOSE GUSHES FOG OIL. |

|

||

| ||||||||||

|

|

TM 3-1040-276-23

TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Step 2. Ignition terminal sleeve contact corroded or insulator

chipped or cracked.

Replace ignition terminal sleeve (p 2-55).

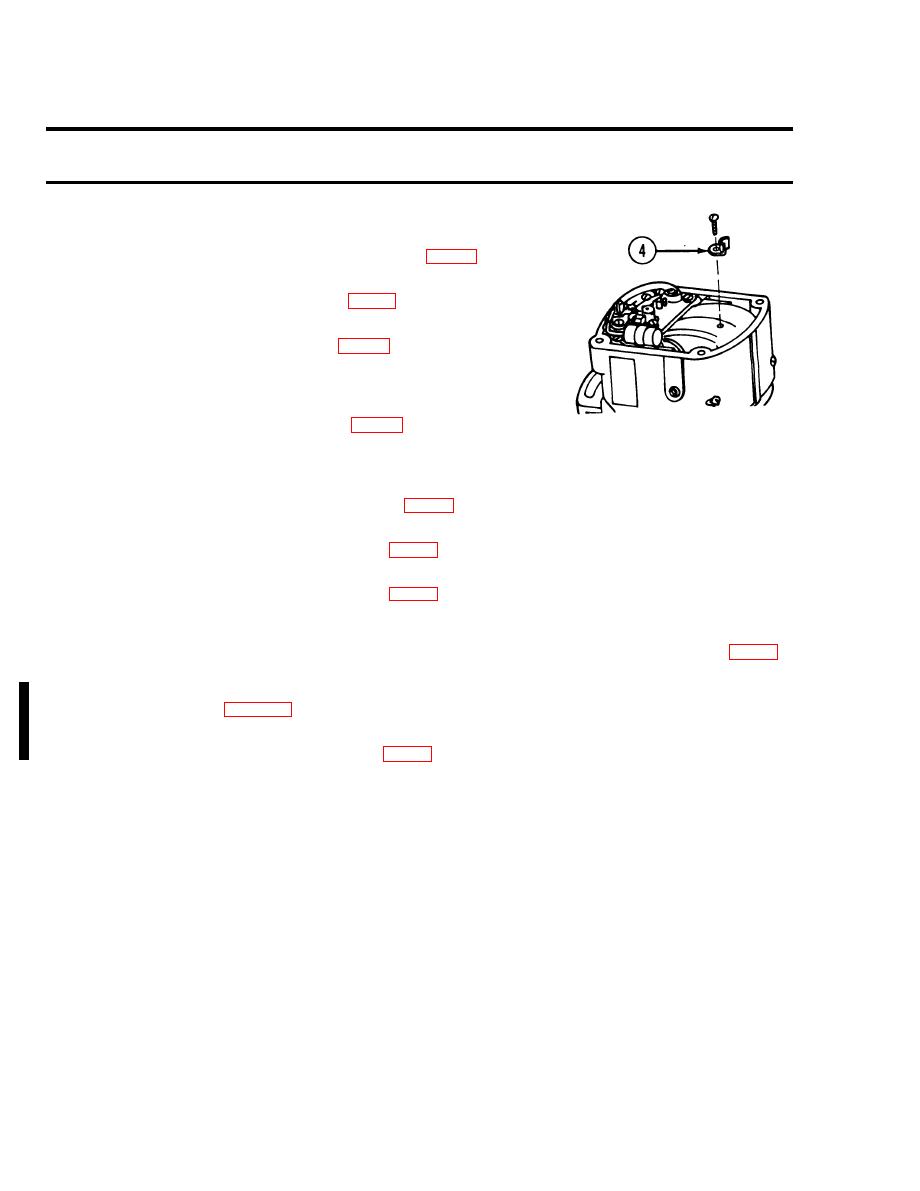

Step 3. Coil clip (4) missing or broken.

Replace coil clip (4) (p 2-55).

Step 4. Capacitor cracked or has broken lead.

Replace capacitor (p 2-55).

Step 5. Contact set points pitted or corroded. Separate

points by inserting screwdriver blade and check

points.

Replace contact set (p 2-55).

Step 6. Contact set point gap may need adjusting. Rotate cam so that breaker arm of contact set sits

on high center. Then check gap between points with 0.015-inch feeler gage. Feeler should

slide in between points with little resistance or play.

Adjust contact set point gap (p 2-55).

Step 7. Coil has cracked insulator or broken leads.

Replace ignition magneto (p 2-51).

Replace ignition magneto (p 2-51).

4. FOG OIL EXHAUST HOSE GUSHES FOG OIL.

Step 1. Test for faulty air check valve assembly disc valve. Remove air check valve assembly (p 2-61).

Shake valve body and listen for rattle.

If disc valve doesn't rattle (won't open or close), repair air check valve assembly

Step 2. Fog oil pump air motor leaks.

Remove M4 fog oil pump (p 2-26) and repair (2-66.7).

Step 3. Pressurizing line clogged.

Report on DA Form 2404 to your supervisor.

Change 1

2-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |