|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 11-6625-2405-15

MAINTENANCE

Section I. ORGANIZATIONAL MAINTENANCE

c. Cleaning (para 3-7)

The maintenance duties assigned to the operator

and organizational repairman of the equipment

are listed below, together with a reference to the

paragraphs covering the specific maintenance

Tools required for organizational maintenance

functions. Required tools and materials are listed

are contained in Tool Kit, Electronic Equipment

TK-101/G. Materials needed are:

a. Daily preventive maintenance checks and

a. Lint-free cloth.

per Federal

services ( para 3-5).

b. Trichloroethane, technical,

b. Monthly preventive maintenance checks and

Specification O-T-620, Type 1.

services (para 3-6).

c. Brush, MIL-G-7241.

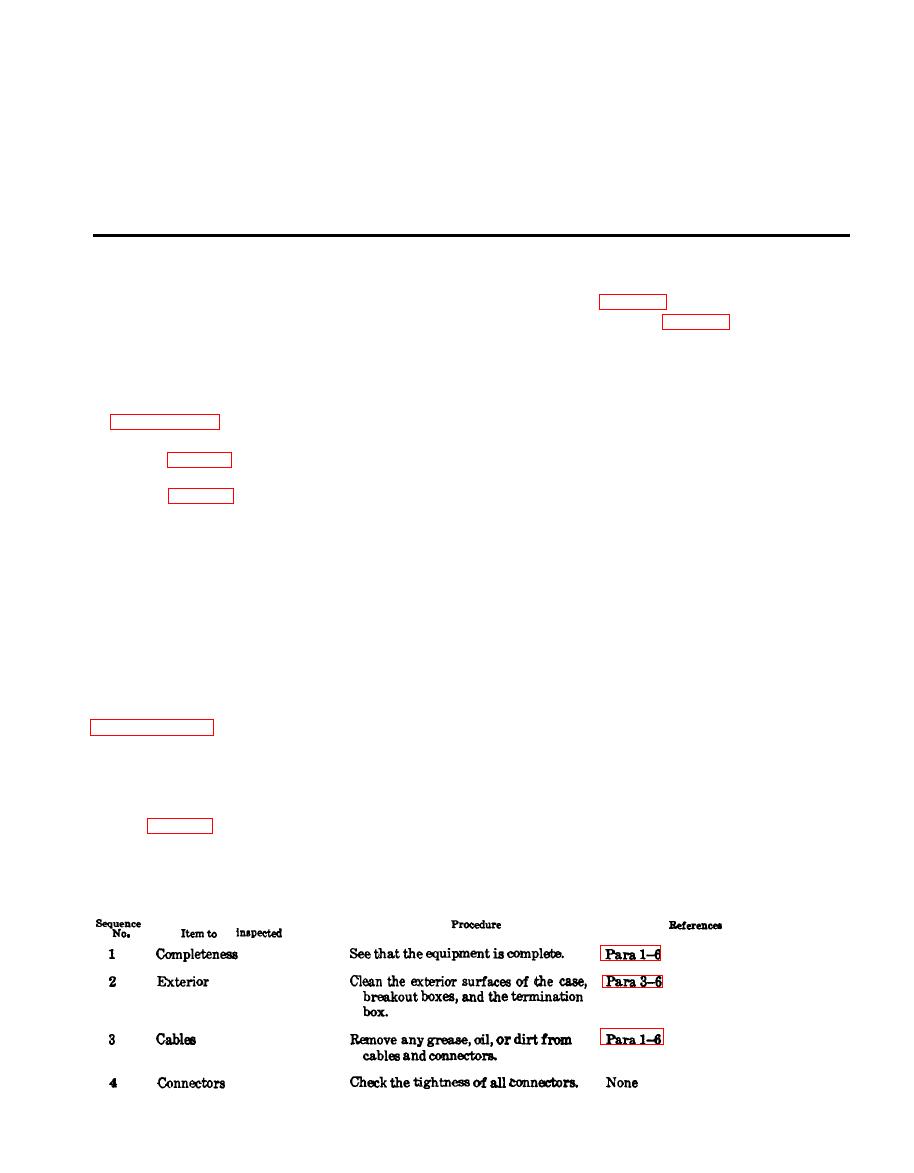

Section Il. PREVENTIVE MAINTENANCE PROCEDURES

maintenance accessories kit is maintained in a

standby condition) and monthly intervals. These

Preventive maintenance is the systematic care,

checks and services are to maintain the equipment

servicing, and inspection of the equipment to

in good general (physical) condition and in good

prevent the occurrence of trouble, to reduce

operating condition. The charts indicate what to

downtime, and to assure that the equipment is

check, how to check, and what the normal condi-

serviceable.

tions are; the References column lists the illustra-

a. Systematic care. The procedures given in

tions, paragraphs, or manuals that contain de-

tailed repair or replacement procedures. If the

tematic care and cleaning essential to proper up-

defect cannot be remedied by performing the cor-

keep and operation of the equipment.

rective actions listed, higher category mainte-

b. Preventive maintenance checks and services.

nance or repair is required. Records and reports

The preventive maintenanoe checks and services

of these checks and services must be made in ac-

charts (para 3-4 and 3-5) outline functions to be

cordance with the requirements set forth in TM

performed daily (or at least once per week if the

33-750.

be

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |