|

|||

|

|

|||

|

Page Title:

Section II PREVENTIVE MAINTENANCE CHECKS AND SERVICES |

|

||

| ||||||||||

|

|

TM 11-5895-555-24

Section II PREVENTIVE MAINTENANCE CHECKS AND SERVICES

checks and services listed in the periodic pre-

4-10. Preventive Maintenance

ventive maintenance checks and services chart

Periodic preventive maintenance checks and

services on the C-8157/ARC and MT3802/ARC

are required. Periodic preventive maintenance

checks and services and must be performed after

100 hours of flying time. All deficiencies or short-

comings will be recorded in accordance with the

requirements of DA Pam 738-750. Perform all the

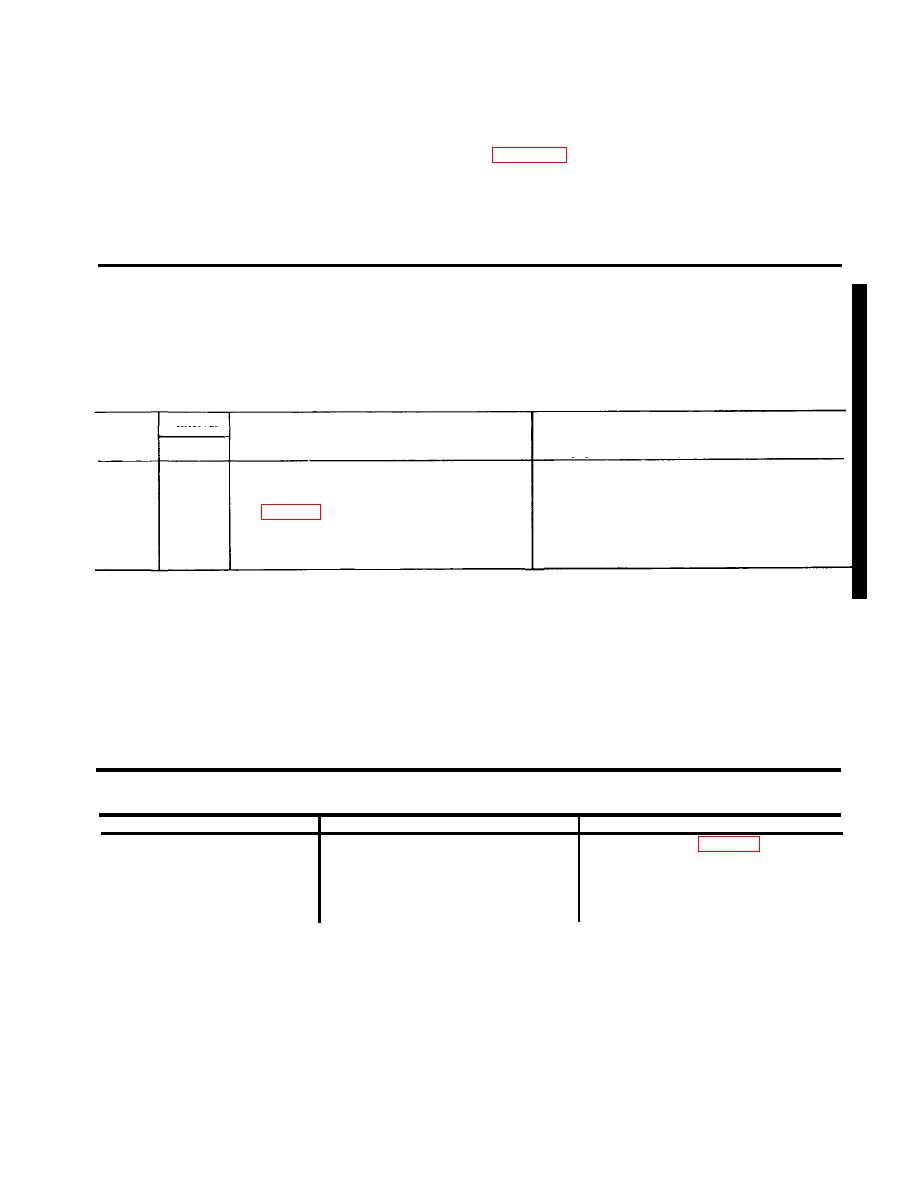

4-11. Preventive Maintenance Checks and Services Chart

NOTE

The checks in the "Interval" column are to be performed in the order listed.

B--Before operation

Item to be inspected

Item

Interval

Equipment is not ready/available if:

Procedure

B

No.

*

Equipment fails to support assigned mission.

1

Control Indicator Performance check.

Perform operational checks as described in

*

Damage to the mounting or equipment.

2

Mounting.

Check and ensure that the TSEC/KY-28

Cipher equipment is mounted securely.

*Do this check before each deployment to a mission location. This will permit any existing problems to be corrected before the mission starts.

The check does not need to be done again until redeployment.

Section III. TROUBLESHOOTING

b. If the corrective measures indicated do not

4 - 1 2 . General

result in correction of the trouble, higher level

a. Control Indicator C-8157/ARC must be re-

maintenance is required.

moved from the aircraft if it fails in any of its

operations during organizational maintenance, or

at anytime it proves to be faulty.

4-13. Troubleshooting Chart

Corrective Action

Probable Cause

Malfunction

a. Defective POWER ON indicator

POWER ON indicator lamp does

b. Press POWER ON switch CB-1

lamp.

not light when POWER ON

to the ON (up) position and

b. POWER ON switch CB-1 has

switch CB-1 is set to ON (up)

release. If CB-1 continues to

tripped to overload.

position.

trip, higher level repair is re-

quired.

4-3

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |