|

|||

|

|

|||

|

Page Title:

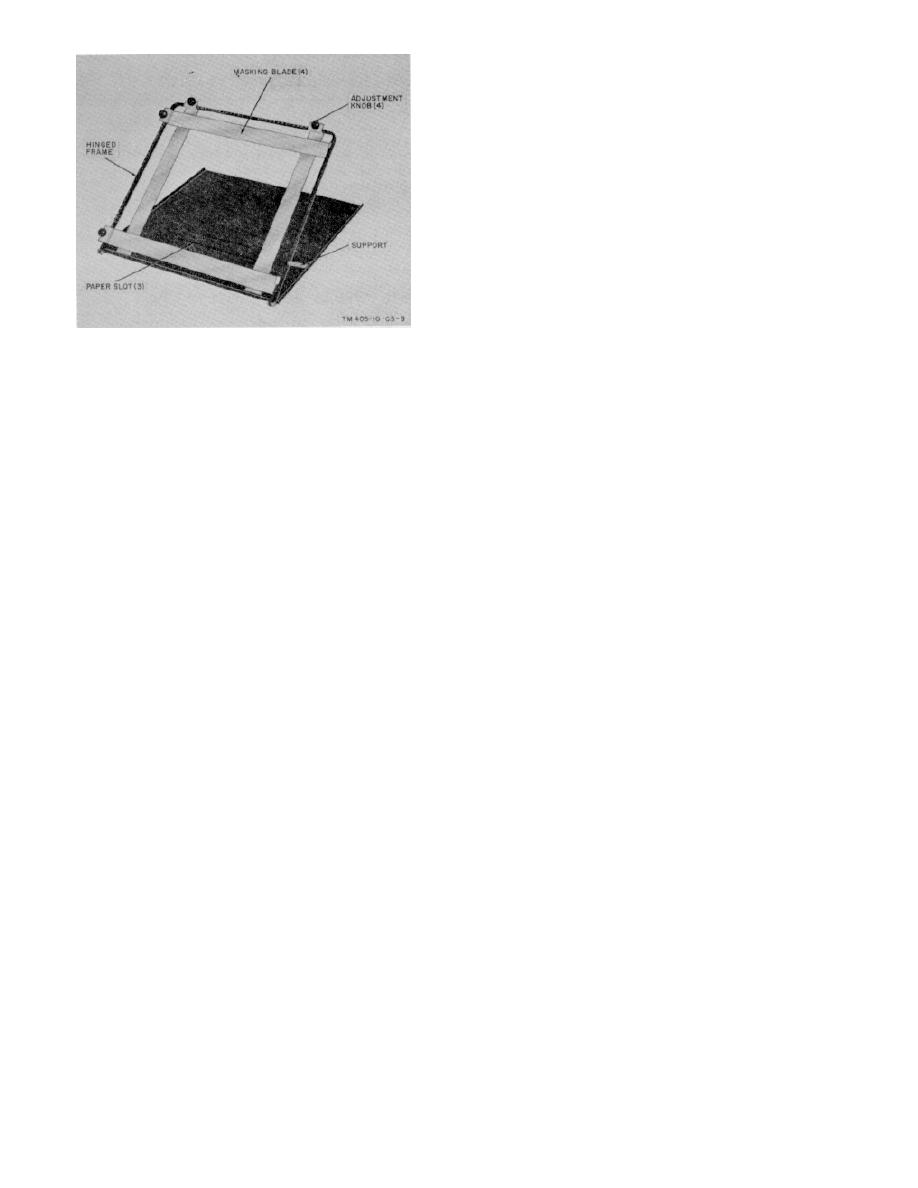

Figure 28.1. Projection Printing Easel EN-10(2). |

|

||

| ||||||||||

|

|

d. Equipment performance checklist (para 35).

e. Repairs (para 36).

32. Materials Required for Maintenance

a.

Cleaning compound (FSN 7930-395-9542).

b.

Lens cleaner (FSN 7930-392-9751).

c.

Lens tissue (FSN 6640-393-2093).

d.

Textile cloth (FSN 8305-267-3015).

33. Preventive Maintenance

Preventive maintenance is the systematic care,

servicing, and inspection of equipment to prevent the

occurrence of trouble, to reduce downtime, and to insure

that the equipment is serviceable.

Figure 28.1. Projection Printing Easel EN-10(2).

a. Systematic Care. The procedures given in

paragraphs 34.1 through 35 cover routine systematic

Page 36, paragraph 24a. Make the following

care and cleaning essential to proper upkeep and

changes:

operation of the equipment.

Heading. Change "Tank PH-526A (fig.

b.

Preventive Maintenance Checks and

29)" to Tank PH-526A or FM-8(2) (fig. 29).

Services. The preventive maintenance checks and

First sentence. Delete and substitute: To

services charts (para 34.1 and 34.2) outline functions to

develop 4by 5-inch cut film by using Tank PH-526A or

be performed at specific intervals. These checks and

FM-8(2), proceed as follows:

services are to maintain Army electronic equipment in a

Page 39, paragraph 25.1 (page 15 of C 3).

combat serviceable condition; that is, in good general

Add "or PH-594A/U" to the heading.

(physical) condition and in good operating condition. To

Figure 31.1 (page 17 of C 3). Delete the caption

assist operators in maintaining combat serviceability, the

and substitute.

chart indicates what to check, how to check, and what

Tank

PH-594A/PFQ

or

PH-594A/U,

the normal conditions are. The References column lists

components.

the illustrations, paragraphs, or manuals that contain

Page 40, paragraph 28, line 2 (page 18 of C 3).

detailed repair or replacement procedures. If the defect

Change "Units ES-20(1) and ES-20(2)" to ES-20(1), ES-

cannot be corrected by the operator, higher category of

20(2), and ES-20(3).

maintenance or repair is required. Records and reports

Page 42 (page 18 of C 3 and as changed by C 2,

of these checks and services must be made in

26 Aug 63).

accordance with the requirements set forth in TM 38-

750.

Delete paragraphs 31 through 34 and substitute:

34.

Preventive Maintenance Checks and Services

31. Scope of Maintenance

Periods

Preventive maintenance checks and services of

The maintenance duties assigned to the

Processing Equipment PH-406 and Photographic Film

operator of Processing Equipment PH-406 and

Processing Units ES-20(1), ES-20(2), and ES-20(3) are

Photographic Film Processing Units ES-20(1), ES-20(2),

required at daily (para 34.1) and weekly (para 34.2

and ES-20(3) are listed below with references to the

intervals. In addition to the routine daily checks and

paragraphs covering the specific maintenance functions.

services, the equipment should be rechecked and

serviced immediately before going on a mission and as

a. Daily preventive maintenance checks and

soon as possible after completion of the mission.

services (para 34.1.

b. Weekly preventive maintenance checks and

services (para 34.2).

c. Cleaning

(para

34.3).

17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |