|

|||

|

|

|||

|

Page Title:

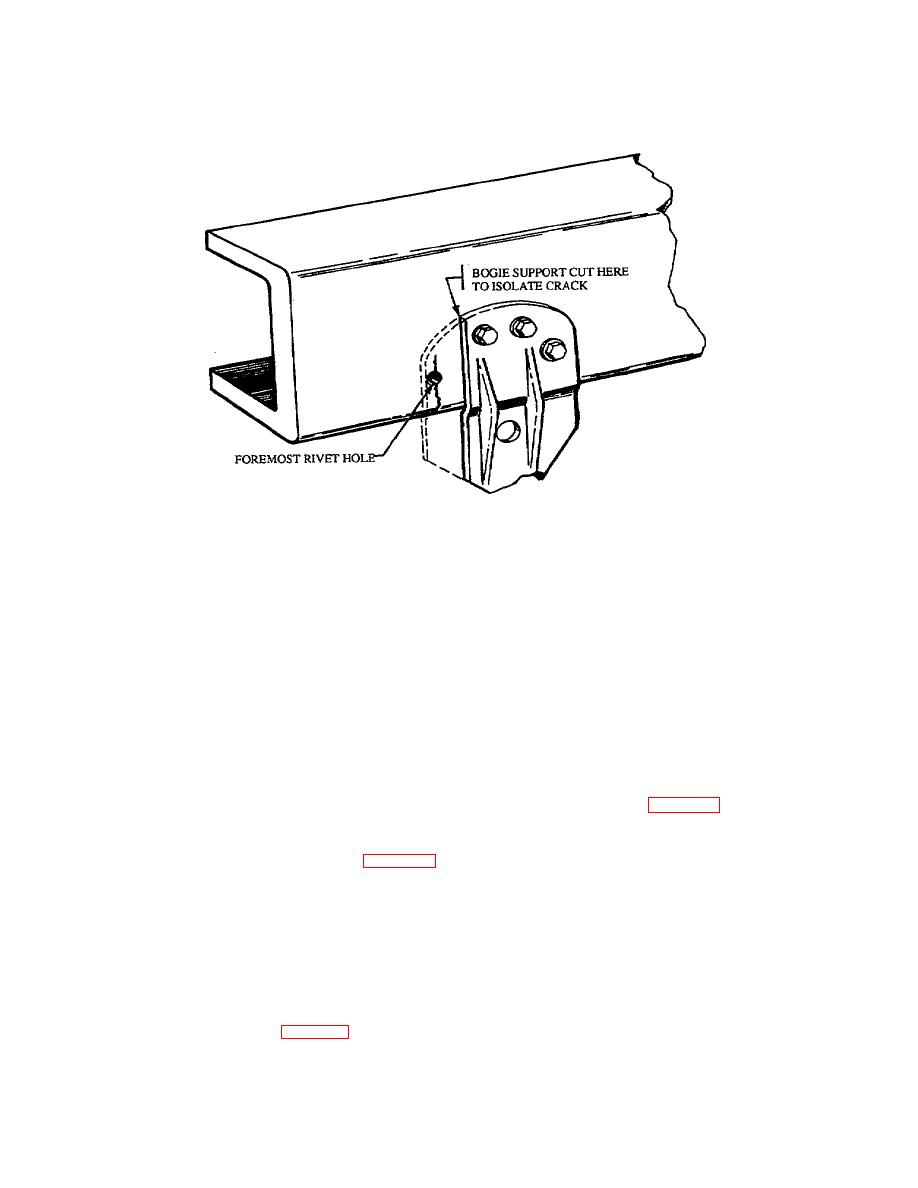

Defect. Cracks Under Bogie Support |

|

||

| ||||||||||

|

|

TB 9-2300-247-40

g. Thoroughly clean repaired

surfaces

and

h. Prime and paint repair area and surrounding

surrounding area of repair.

surfaces as specified in TM-43-0139.

Figure 40. Isolation of Crack In Bogie Support

e. Thoroughly clean repaired

surfaces

and

55.

Defect. Cracks Under Bogie Support. Cracks

surrounding area of repair.

located under bogie supports requiring removal of the

support assembly.

f.

Prime and paint repair area and surrounding

surfaces as specified in TM-43-0139.

WARNING

56.

Defect. Cracks In Lower Flange of Frame

Use Only effective chip guarding

Rail. Cracks in lower flange of frame rail at the bogie

equipment, protective equipment and

support.

protective clothing (goggles, shields,

gloves aprons, etc) when doing any

a. Sketches. Prepare sketches to design specific

drilling, grinding, or welding. Failure

repair requirements as required and/or as shown

to follow this warning could result in

in this section.

injury to personnel.

b. Fabricate doubler plate from prepared sketches

a. Cut bogie support to provide space around the

and as shown in Figure 42.

area of the vehicle frame to be welded.

c.

Using C- clamps, insure that frame rails are in

b. Cut the support by drilling a series of holes at the

alinement and in close contact with the doubler.

proposed welding point as shown in figure 41.

Chisel through holes, and grind separated

d. Grove the side rail and weld into the liner with

surfaces to a smooth finish with a portable

the doubler plate in place.

grinding tool.

e. Thoroughly clean repaired

surfaces

and

c.

Sketches. Prepare sketches to design specific

surrounding area of repair.

repair requirements as required and/or as shown

in this section.

f.

Prime and paint repair area and surrounding

surfaces as specified in TM-3-01 39.

d. Fabricate and install doubler plate from prepared

sketches and as shown in figure 42.

36

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |