|

|||

|

|

|||

|

Page Title:

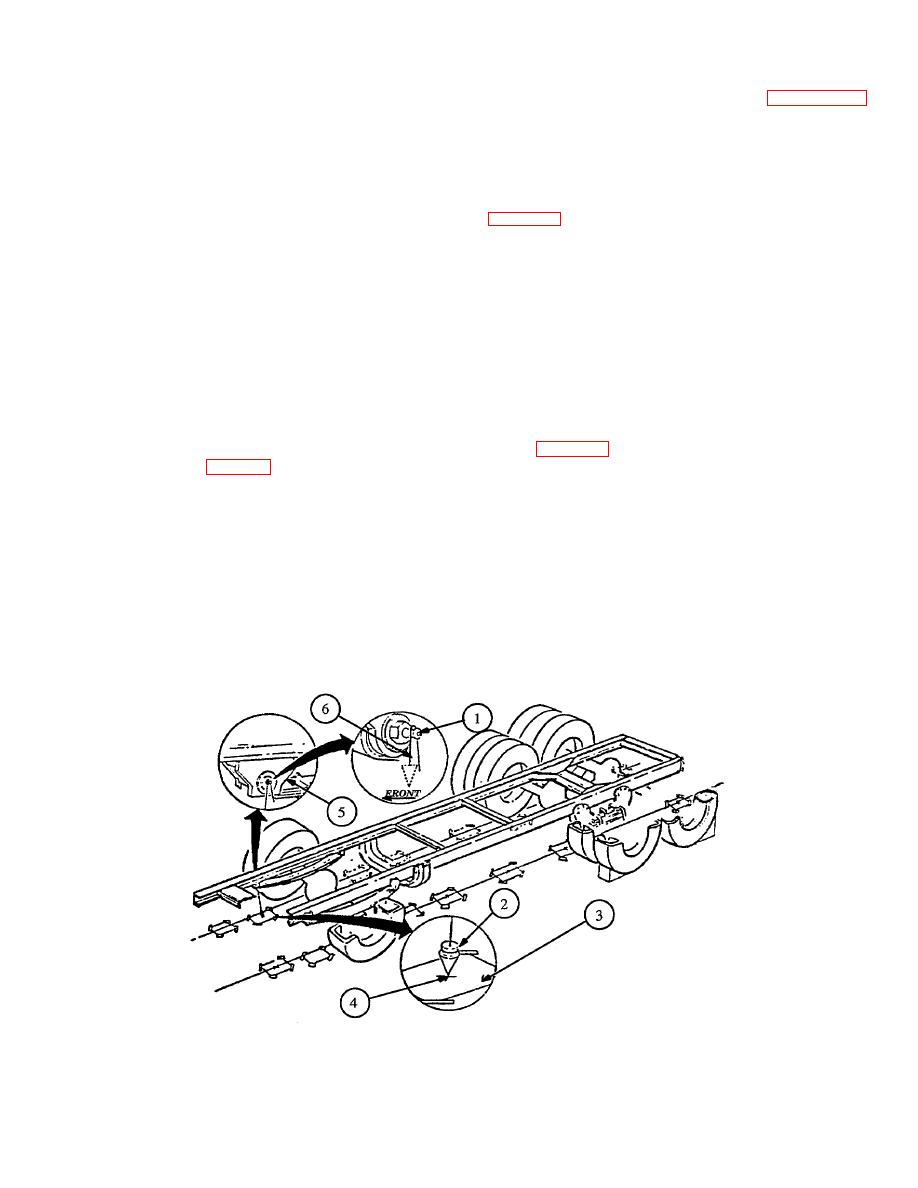

Horizontal Bow Measurements -Vehicle Frames Over 20 Feet (Figure 9). |

|

||

| ||||||||||

|

|

TB 9-2300-247-40

a.

Perform steps a thru c of paragraph 33

NOTE

above for each 20 foot section of frame rail.

For frame rail sections with added

If frame rail exceeds the tolerances

flaseplate, subtract 5/16-in.

from

specified, the vehicle will be classified

plumb bob mark to compensate for

unserviceable.

the flaseplate added to the frame rail.

35.

Frame Squareness - All Vehicle Frames

b. Record measurements (A) and (B)

on DA Form 2404.

NOTE

NOTE

This procedure requires that the

To verify frame rail tolerance

vehicle right and left front spring

measurement, have another qualified

shackles be equipped with straight

shop

technician

repeat

mark

type grease fittings.

measurement steps a and b.

If

second measurements verify frame

M39 series vehicles modified with

rail out of tolerance condition, vehicle

M809

vehicle

power

steering

will be classified as unserviceable.

conversion kit will have a grease

fitting installed on the in- side of the

c.

Record second measurements (A) and (B).

right front spring shackle (re- fer to

34.

Horizontal Bow Measurements -Vehicle

Frames Over 20 Feet (Figure 9).

a.

Locate and clean the two front grease

fittings (1) on right and left front spring front

NOTE

shackles (2).

On vehicles with frames over 20 feet

in length, the forward (front) 20 feet

b.

Check that grease fittings (1) are straight

of frames rail is measured separately

type. If not, replace with straight type

from the rear (back) 20 feet of frame

grease fittings.

rail. The front 20 feet of frame rail will

be measured from front to rear and

c.

Using tape, securely attach sheet paper (3)

the rear 20 feet of frame rail will be

to shop floor directly under right and left

measured from rear to front. This will

front spring front shackles (2)

cause an overlap in measurements.

Figure 11. Marking Paper Under Right Spring Shackle

13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |