|

|||

|

|

|||

|

Page Title:

Table 2-1. Storage Induced Quality Defect Assignment Code Guideline (AR 740-3, Appendix B) |

|

||

| ||||||||||

|

|

SB 740-91-01

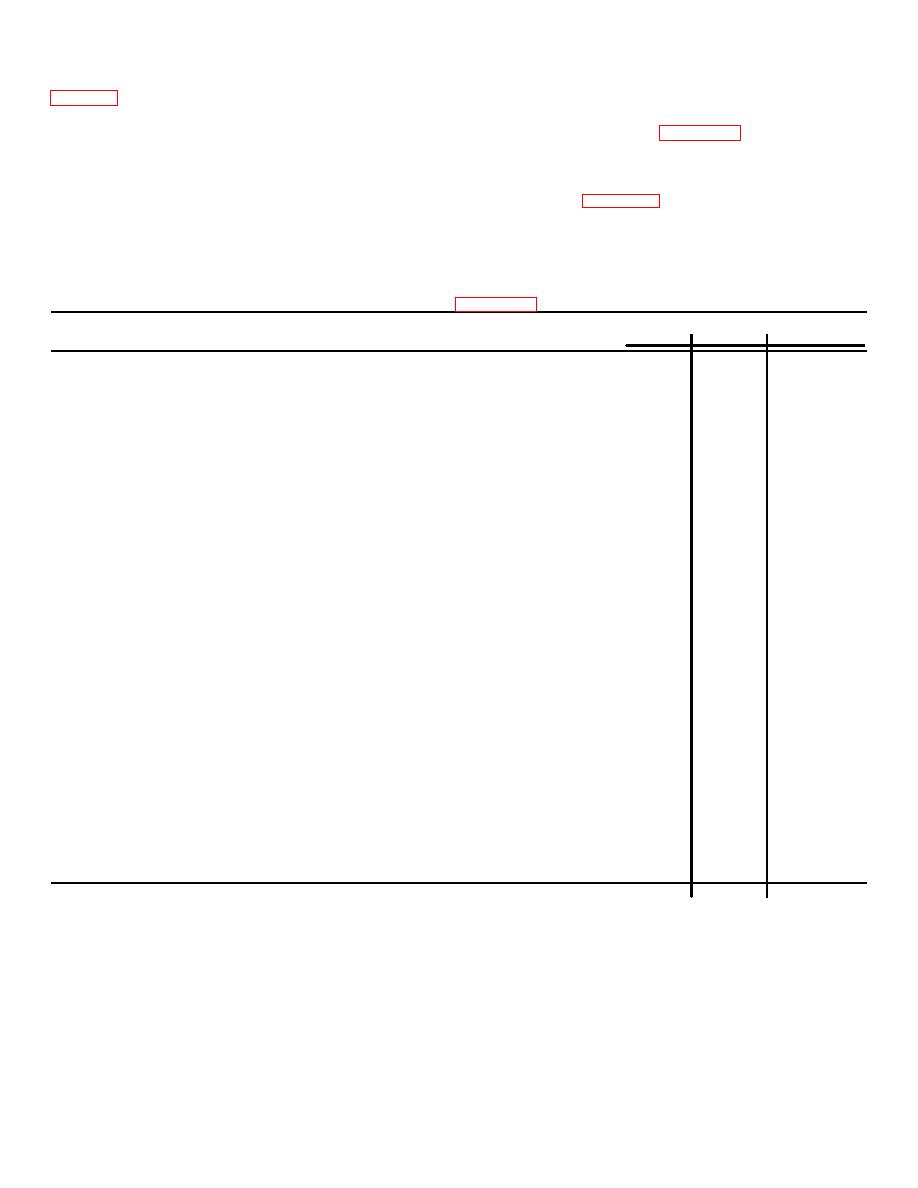

Table 2-1 provides a modified list of materiel quality defects and severity levels that are of most concern during extended

periods of storage and which formed the basis for assigning the coded accept/reject requirements for cyclic inspections.

The required quality defects/severity level inspection codes for each materiel item found in appendix A were derived from

this modified list. The individual defect/severity level codes were assigned in accordance with their potential impact on the

readiness of the materiel items and based on factors of cost effectiveness and probability of occurrence. Other

discrepancies that may be observed during cyclic inspection not covered by the preassigned QDC codes shall be

classified in accordance to severity, recorded on the appropriate work sheet (see Figure 2-2), and taken into account when

determining lot acceptance.

Table 2-1. Storage Induced Quality Defect

Assignment Code Guideline

(AR 740-3, Appendix B)

Second and

Severity Code (First Digit)

Third Digit

Category

Critical

Major

Minor

02

Preservation Inadequate

2

13

Container Damaged or Deteriorated

2

23

Containers, Boxes, Crates, or Pallets

1

2

Damaged or Deteriorated

33

Markings Illegible

2

40

Loose or Frozen Parts (out of adjustment)

0

1

2

41

Damaged Parts (cracked, chipped, torn)

0

1

2

2

45

Leakage (liquid)

0

1

48

Bonding Deterioration (soldering, welding,

0

1

2

etc.)

50

Contamination (dirt, sludge, moisture,

2

foreign matter)

51

Excessive Moisture (fungus, mildew, rot)

2

55

Shelf-life Data Exceeded

0

62

Failed Test Requirements (failed supplemen-

0

1

2

tary test functional/visual)

86

Improper Storage Space

1

2

90

Corrosion, Stage 1 (or more)

1

2

It should be noted when classifying a defect which is not considered critical, major, or minor at the time of inspection but

(due to inspector experience) is expected to become so prior to the next cyclic inspection, the defect shall be identified as

such and considered as a cause for rejection and counted relative to the items' sampling plan criteria. However, defects of

a trivial nature should not be considered as cause for rejection of a lot, unless some reduction in usability or function of

items is expected prior to the next scheduled inspection. For example, nicks, dents, or scratches that do not break

coatings or paint films are considered trivial deficiencies.

2-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |