|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

FUEL SYSTEM

TESTING AND ADJUSTMENT

9. Adjust dial indicator (8) so both pointers (10) are on "0"

(Zero).

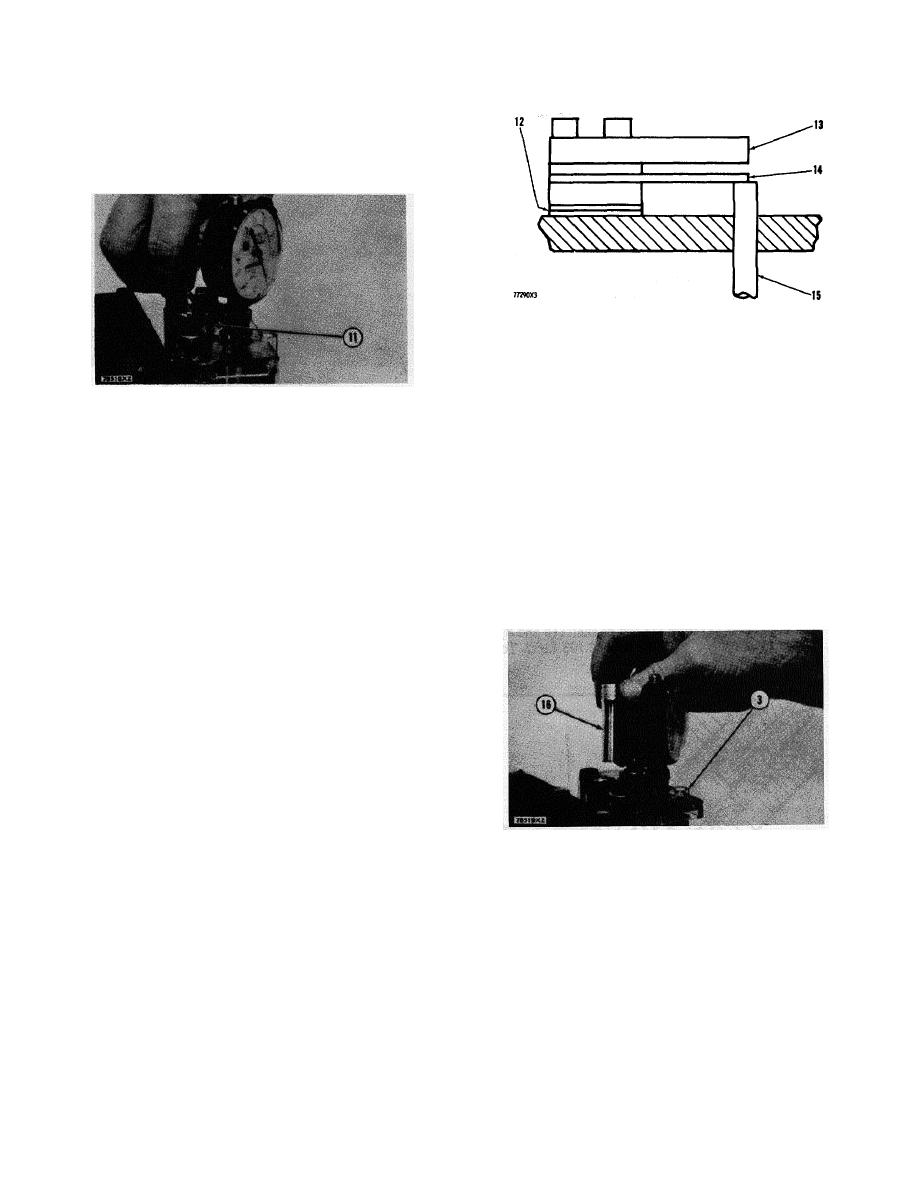

10. Using wrench (11) turn the 8S7271 Screw (6)

counterclockwise. Turn screw (6) six or more turns.

LEAF TYPE TORQUE SPRING

12. Location of shims. 13. Stop bar. 14. Leaf

type torque spring. 15. Load stop pin.

e. Install the correct amount of shims (12) torque

spring (14), and stop bar (13) on the housing for the

LOOSENING SCREW (6)

fuel injection pumps.

11. 1S9836 Wrench.

f. Install the test tools and do the test procedure again.

11. Put the clip end of the 8S4627 Circuit Tester to a good

Do this until the dimension on the dial indicator is

ground. Put the other end of the 8S4627 Circuit Tester

the same as the dimension given in the RACK

on the load stop contact. Put this end of the 8S4627

SETTING INFORMATION. After the fuel setting is

Circuit Tester through the large hole on top of cover

correct, remove the test tools. Install cover (2) and

(3).

shut-off solenoid (1).

12. Move the governor control lever to the LOW IDLE

Load Stop Adjustment

position.

a. Put socket (16) in the large hole in cover (3).

13. Move the governor control lever slowly toward the

HIGH IDLE position until the continuity light just comes

on. Make a note of the reading on dial indicator (8).

Do this step several times to make sure the reading is

correct.

14. Make a comparison of this reading and the fuel setting

in the RACK SETTING INFORMATION.

15. If the reading on dial indicator (8) is not correct, do the

following.

Leaf Type Torque Spring

PUTTING SOCKET IN COVER

a. Write down the dimension that is on dial indicator

3. 2P331 Cover. 16. 3P221 Socket.

(8).

b. Write down the dimension given in the RACK

b. Use wrench (21) with socket (16) and loosen locknut

SETTING INFORMATION.

(18).

c. Remove the test tools [cover (3), spring (4), and dial

c. Using screwdriver (20), turn adjustment screw (17)

indicator (10)] from the housing for fuel injection

until the reading on dial indicator (8) is the same as

pumps.

the dimension given in the RACK SETTING

d. Install or remove shims at location (12) to get the

INFORMATION.

correct dimension as given in the RACK SETTING

INFORMATION.

The difference between the

d. When the adjustment is correct, tighten locknut

dimensions in (a) and (b) is the thickness and

(18). Check the adjustment again by doing Steps

amount of shims to remove or install to get the

11 through 15 again.

correct setting.

59

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |