|

|||

|

|

|||

|

Page Title:

FLOW OF FUEL USING THE PRIMING PUMP |

|

||

| ||||||||||

|

|

FUEL SYSTEM

SYSTEMS OPERATION

(90N1-90N6120)

rpm and position of governor weights (28). Any

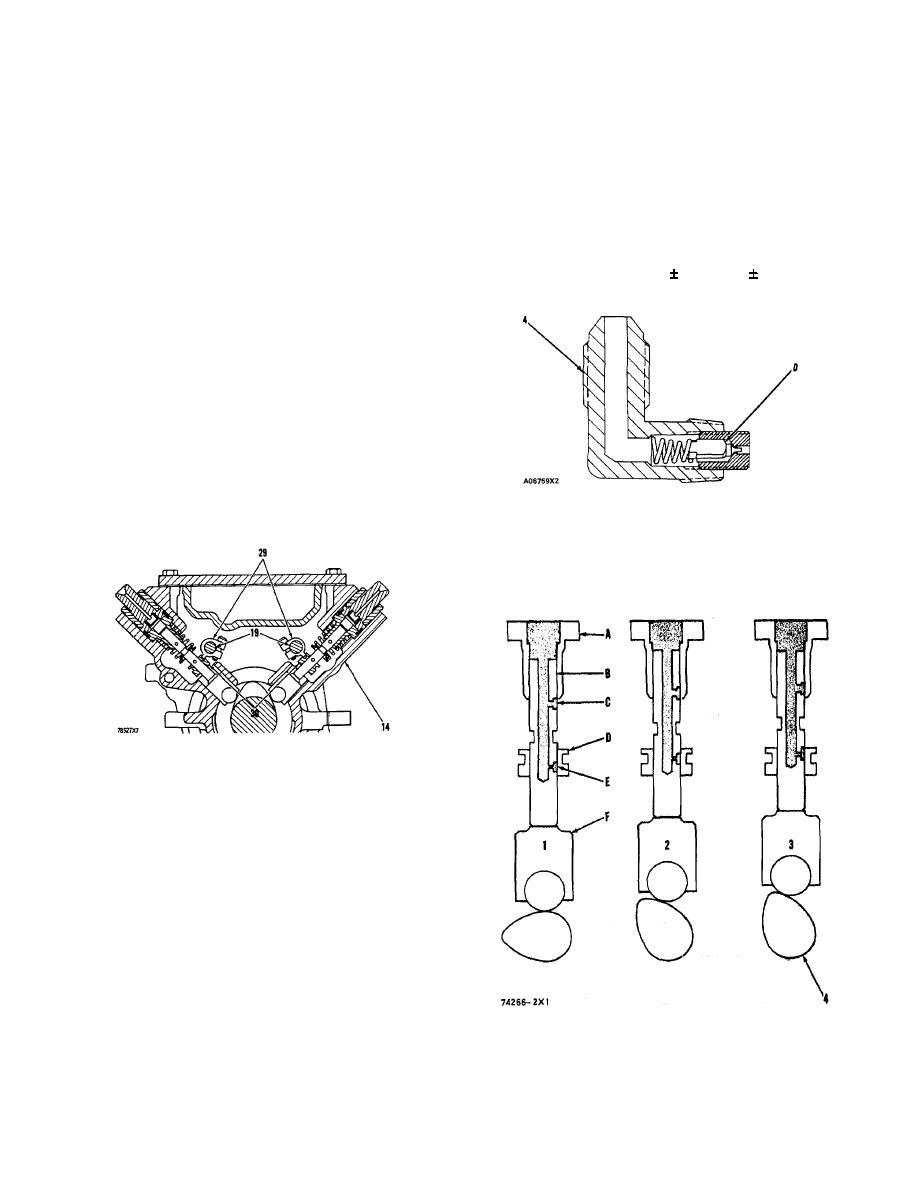

CONSTANT BLEED VALVE

change of governor weight position will cause

thrust collar (25) to move. As governor weights

Constant bleed valve (4) lets approximately 9

(28) turn faster, thrust collar (25) is pushed toward

gallons of fuel per hour go back to fuel tank (7).

governor springs (23). When the force of governor

This fuel goes back to fuel tank (7) through return

springs (23) is balanced by the centrifugal force of

line for constant bleed valve (3). This flow of fuel

the governor weights, sleeves (30) of the injection

removes air from housing (14) and also helps to

pumps are held at a specific position to send a

cool the fuel injection pump. Check valve (D)

specific amount of fuel to the engine cylinders.

makes a restriction in this flow of fuel until the

pressure in housing (14) is at 8 3 psi (0.6 0.2

When the governor control lever is turned

kg/cm2 ).

toward the FUEL-OFF position with the engine

running, there is a reduction of force on governor

springs (23). The movement of the linkage in the

governor will cause fuel control shafts (19) to

move sleeves (30) down, and less fuel will be

injected in the engine cylinders.

To stop the engine, turn the ignition switch to

the "OFF" position. This will cause the shut-off

solenoid to move linkage in the fuel pump housing.

Movement of the linkage will cause sleeve levers

(29) to move sleeves (30) down, and no fuel is sent

to the engine cylinders. With no fuel going to the

CONSTANT BLEED VALVE

engine cylinders, the engine will stop.

4. Constant bleed valve. D. Check valve.

OPERATION OF FUEL INJECTION PUMPS

FUEL SYSTEM COMPONENTS

14. Housing for fuel injection pumps. 19. Sleeve control

shafts. 29. Sleeve levers. 30. Sleeves.

FLOW OF FUEL USING THE PRIMING PUMP

When the handle of priming pump (2) is pulled

out, negative air pressure in priming pump (2)

opens check valve (A) and pulls fuel from fuel tank

(7). Pushing the handle in closes check valve (A)

and opens check valve (B). This pushes air and/pr

fuel into housing (14) through the fuel passages

and check valve (C). More operation of priming

pump (2) will pull fuel from fuel tank (7) until the

fuel lines, fuel filter (9) and housing (14) are full of

fuel. Do this until the flow of fuel from manual

FUEL INJECT!ON SEQUENCE

bleed valve (5) is free of air bubbles. Relief valve

1, 2. 3. Injection stroke (positions) of a fuel injection pump.

(10) will open and let the fuel go to the inlet for

4. Injection pump camshaft. A. Barrel. B. Plunger. C.

fuel priming pump (2} if the pressure gets higher

Fuel inlet. D. Sleeve. E. Fuel outlet. F. Lifter.

than 20 psi (1.4 kg/cm ) when using priming pump (2).

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |