|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

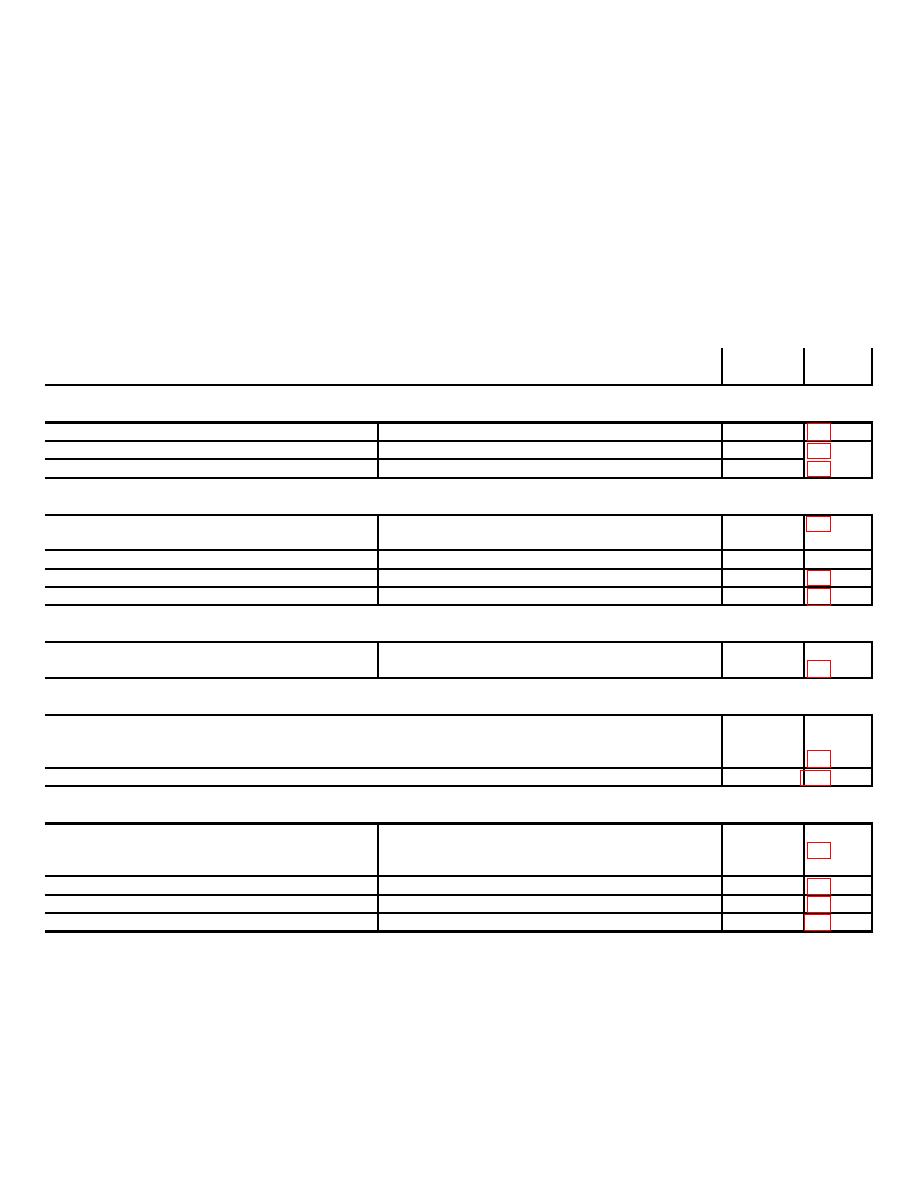

SERVICE INTERVALS

The service meter is the most reliable method of determining service intervals. The service meter shows the total

number of units your engine has run. Perform the maintenance at multiple intervals of units shown. For example when

the service meter shows "100" on the dial, all items listed under "EVERY 10 SERVICE METER UNITS" should be

serviced now for the tenth time, and all items under "EVERY 50 SERVICE METER UNITS" should be serviced for the

second time.

If your engine does not have a service meter, use the calendar interval. These figures are based on a 10 hour day

and a 2000 hour year. If your operation differs from these limits, base your service intervals on actual running time.

Keep an accurate record of operating time.

Items which do not pertain to your engine may be lined out to customize your charts.

SERVICE ITEMS AND PROCEDURES

LUBE

PAGE

FREQUENTLY DURING OPERATION

Check oil pressure gauge reading.

Observe all gauge readings. Note any change

-

Check water temperature gauge reading.

from the NORMAL reading and determine

-

Check ammeter reading.

the cause. Have necessary repairs made.

-

EVERY 10 SERVICE METER UNITS OR DAILY

Check crankcase oil level.

Maintain between ADD and FULL mark

CD or CC

on dipstick.

Fill fuel supply tank after stopping.

See "Key to Fuels, Lube & Water", Pg. 9

-

15

Check engine coolant level.

Maintain level 1/2" below fill pipe.

-

Check clutch adjustment.

Should engage with distinct snap.

EVERY 50 SERVICE METER UNITS OR WEEKLY

Check electrolyte level of battery cells.

Fill only with make-up water, See "Key to

Fuels, Lubricants and Water", Pg. 9

-

EVERY 100 SERVICE METER UNITS OR 2 WEEKS

Check inlet and exhaust valve lash. (See

Initial adjustment for new and

Note 4)

reconditioned engines only.

See valve lash setting, Pg. 10

Lubricate flywheel clutch lever bearings.

2 fittings - 2 strokes

MPGM

EVERY 150 SERVICE METER UNITS OR 3 WEEKS

Change engine oil and oil filter. (See Note 2)

Drain and refill. Refill capacity 12 qts.

CC

(11.5 ltrs.)

(See

Note 1)

Change air cleaner elements. (See Note 3)

Install a new or a cleaned element.

Check fan and drive belt wear and tension.

Maintain belt tension as indicated in chart

Check flywheel clutch oil level.

Keep at proper level.

CD or CC

8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |