|

|||

|

|

|||

|

Page Title:

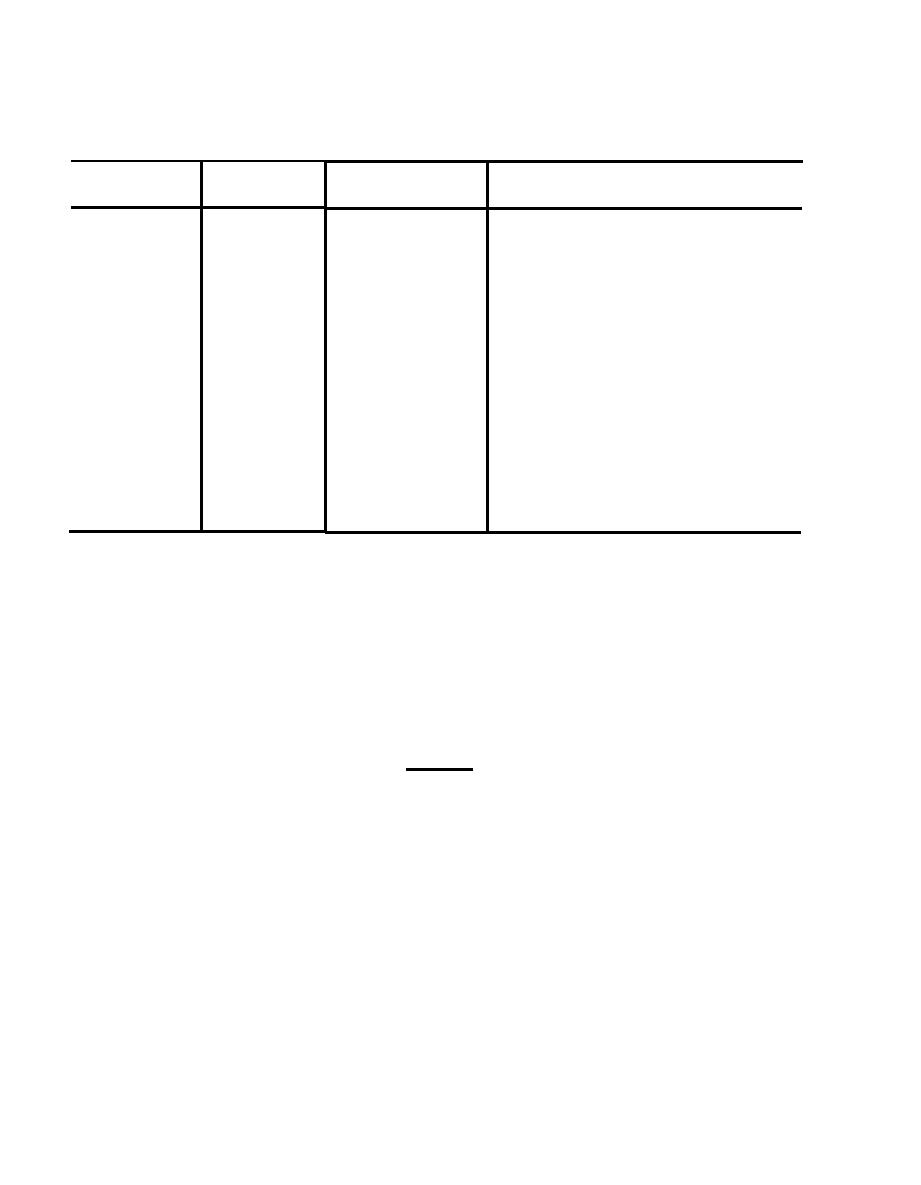

Table 5-9. Indicator Lamp Assembly (A18, A19), Inspection |

|

||

| ||||||||||

|

|

TM 32-5865-069-24&P

Indicator Lamp Assembly (A18, A19), Inspection

Inspection

Normal

Procedure

Component

method

condition

Indicator

Visual

a thru d must

a.

Check the assembly for

loose, missing or damaged

be free of

Light Assy

defects.

hardware.

b.

Check lamp contacts for

dirt, corrosion and damage.

Check for continuity between

c.

lamp contacts and printed

wiring board connections

using a multimeter.

Examine the printed wiring

d.

board, check-for broken or

cracked board, dry joints or

excessive solder, lifted or

broken tracks.

(3) Insert the blade of the screwdriver between the retaining spring and

the top of the sleeve. Gently depress the spring to release the

.

assembly from the sleeve.

(4) Ensure the replacement lens is fitted with serviceable lamps.

(5) Insert the lens into the sleeve and push gently until the retaining

spring snaps into place.

b. Replace Indicator Assembly/Printed Wiring Board as follows:

CAUTION

Use a low temperature soldering iron tip or appropriate heat-sink to

avoid damage to printed wiring board.

Refer to NAVTORPSTA REPORT

1347

(1) Use solder wick or suction to remove solder from all connections to

the printed wiring board.

(2) Remove and retain the four screws securing the printed wiring board to

the assembly.

(3) Remove the board from the assembly.

(4) Discard the faulty component.

(5) Assemble the replacement part to the component retained in step b.(4).

5-46

.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |