|

|||

|

|

|||

|

Page Title:

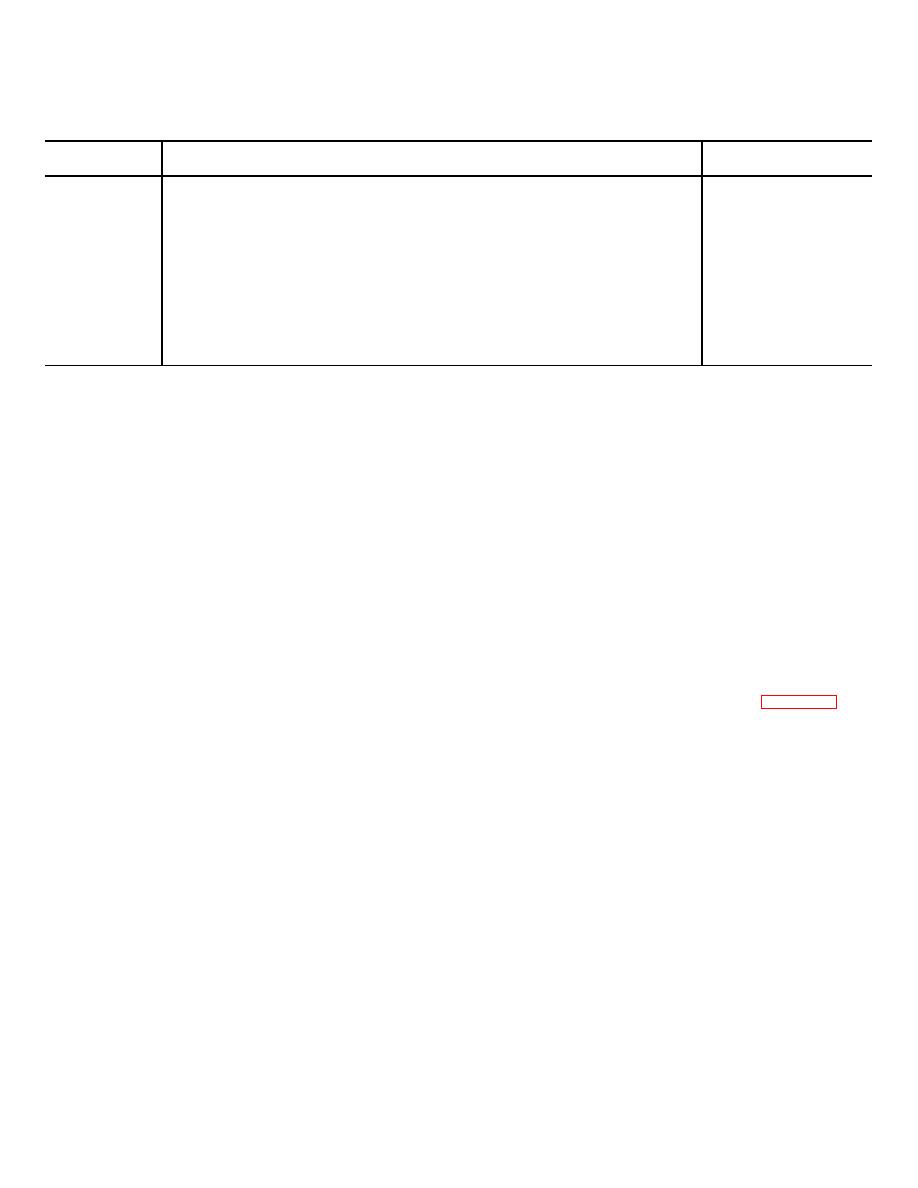

Table 4-3. Organizational Quarterly Preventive Maintenance Checks and Services |

|

||

| ||||||||||

|

|

TM 11-6625-542-14-1

Table 4-3. Organizational Quarterly Preventive Maintenance Checks and Services

Q- Quarterly

Time required: 0.3

Sequence No. Item to be inspected procedure

Work time M/H

1

PUBLICATIONS:

0.1

See that all publications are complete, serviceable and current. Refer to DA

Pam 310-4.

2

MODIFICATIONS:

0.1

Check DA Pam 310-7 to determine if new applicable MWO's have been

published. All URGENT MWO's must be applied immediately. All NORMAL

MWO's must be scheduled.

3

SPARE PARTS:

0.1

Check all spare parts (operator and organizational) for general condition and

method of storage. There should be no evidence of overstock, and all

shortages must be on valid requisitions.

soft clean cloth. If necessary, dampen the cloth with

4-4. Cleaning

water and mild soap.

The exterior surfaces should be clean, and free of dust,

4-5. Rustproofing and Painting

dirt, grease and fungus.

a. Remove dust and loose dirt with a clean, soft

a. Rustproofing. When the finish becomes badly

cloth.

scarred or damaged, rust and corrosion can be

prevented by touching up the bare surfaces. Use No.

WARNING

000 sandpaper to clean the surface down to the bare

The fumes of trichloroethane are toxic. Provide

metal. Obtain a bright, smooth finish.

thorough ventilation whenever used. DO NOT

b. Painting. Remove rust and corrosion from

use near an open flame. Trichloroethane is not

metal surfaces by lightly sanding them with fine

flammable but exposure of fumes to an open

sandpaper. Brush two thin coats of paint on the bare

flame converts flame to highly toxic, dangerous

metal to protect it from further corrosion. Refer to the

fumes.

applicable cleaning and refinishing practices specified in

TB 43-0118.

b. Remove grease, fungus, and ground-in dirt

4-6. Troubleshooting Information

from the cases; use a cloth dampened (not wet) with

trichloroethane.

To troubleshoot the equipment, perform all functions of

c. Remove dust or dirt from output jacks and

the AN/USM-108A operation until an abnormal condition

connectors with a brush.

or result is observed. Note the abnormal condition, or

d. Remove the air filter and gently tap on a hard

result, and refer to troubleshooting table 4-4 for

surface to dislodge dust and dirt. Agitate the filter in

corrective action. If the corrective measures indicated do

soapy water, rinse thoroughly in clean fresh water and

not result in correction of the trouble or if no

dry.

corresponding measure is listed in the troubleshooting

e. Clean the front panel and control knobs; use a

table, higher category of maintenance is required.

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |