|

|||

|

|

|||

|

Page Title:

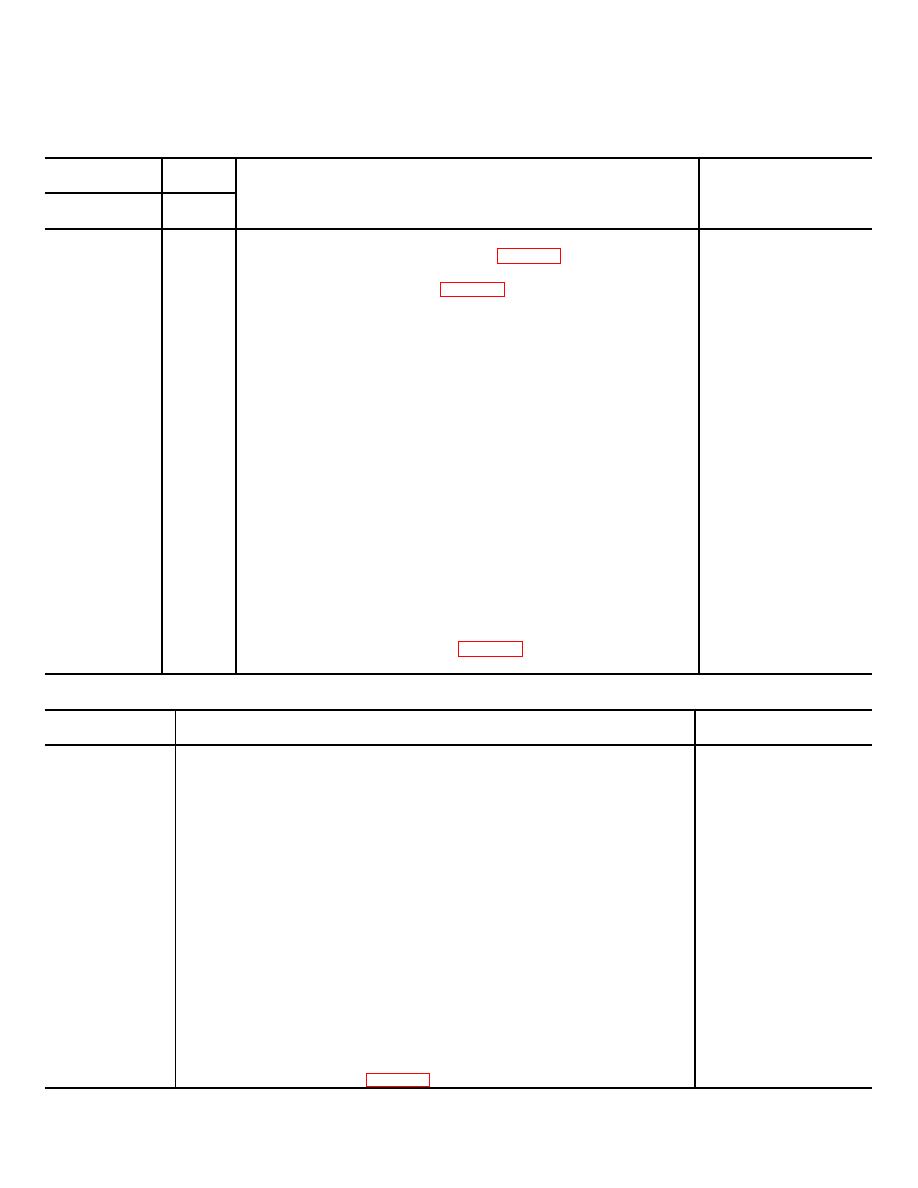

Table 4-1. Operator Daily and Weekly Preventive Maintenance Checks and Services |

|

||

| ||||||||||

|

|

TM 11-6625-542-14-1

Table 4-1. Operator Daily and Weekly Preventive Maintenance Checks and Services

D- Daily

W-Weekly

Time required: 0.5

Time required. 1.6

Interval and

sequence No.

D

W

Item to be inspected procedure

Work time M/H

1

0.1

See that equipment is complete (table 1-1).

2

EXTERIOR SURFACES:

0.1

Clean exterior surfaces (para 4-4). Check indicator lenses for

cracks.

3

CONNECTORS AND CABLES:

0.1

Check all connectors and cables for tightness, cracks and

overall condition.

4

CONTROLS AND SWITCHES:

0.1

Observe that the mechanical action of each pushbutton and

switch is smooth and free of external or internal binding, and

that there is no excessive looseness.

5

INDICATOR LAMPS:

0.1

Set POWER ON switch to ON and observe that POWER ON

indicator and CRYSTAL HEATER indicator both illuminate.

6

CABLES AND CORDS:

0.1

Inspect cords, cables and wires for chafed, cracked or frayed

insulation. Replace connectors that are broken, arced,

stripped or worn excessively.

7

HANDLE:

0.1

Inspect handle for looseness. Replace or tighten as

necessary.

8

METAL SURFACES:

0.2

Inspect exposed metal surfaces for rust and corrosion.

Touchup paint as required (para 4-5).

Table 4-2. Organizational Monthly Preventive Maintenance Checks and Services

M- Monthly Time required: 0.11

Sequence No.

Item to inspected procedure

Work time M/H

1

PLUCKOUT ITEMS:

0.2

Inspect seating of pluckout items. Make certain that tube clamps grip tube

bases tightly.

2

TRANSFORMER TERMINALS:

0.1

Inspect terminals on power transformer. There should be no evidence of

dirt or corrosion.

3

TERMINAL BLOCKS:

0.1

Inspect terminal blocks for loose connections and cracked or broken

insulation. Be sure silver solder connections are not loose from ceramic

backing.

4

RESISTORS AND CAPACITORS:

0.2

Inspect resistors and capacitors for cracks, blistering or other detrimental

defects.

5

GASKETS AND INSULATORS:

0.2

Inspect gaskets, insulators, bushings and sleeves for cracks, chipping and

excessive wear.

6

INTERIOR:

0.1

Clean interior of chassis and cabinet.

7

AIR FILTER:

0.2

Remove and clean air filter (para 4-4).

4-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |